Method for making curved frequency selective surface by three-dimensional printing technology

A frequency-selective surface and three-dimensional printing technology, which is applied in image data processing, instruments, etc., can solve the problems of unsuitable and non-expandable surface FSS, etc., and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

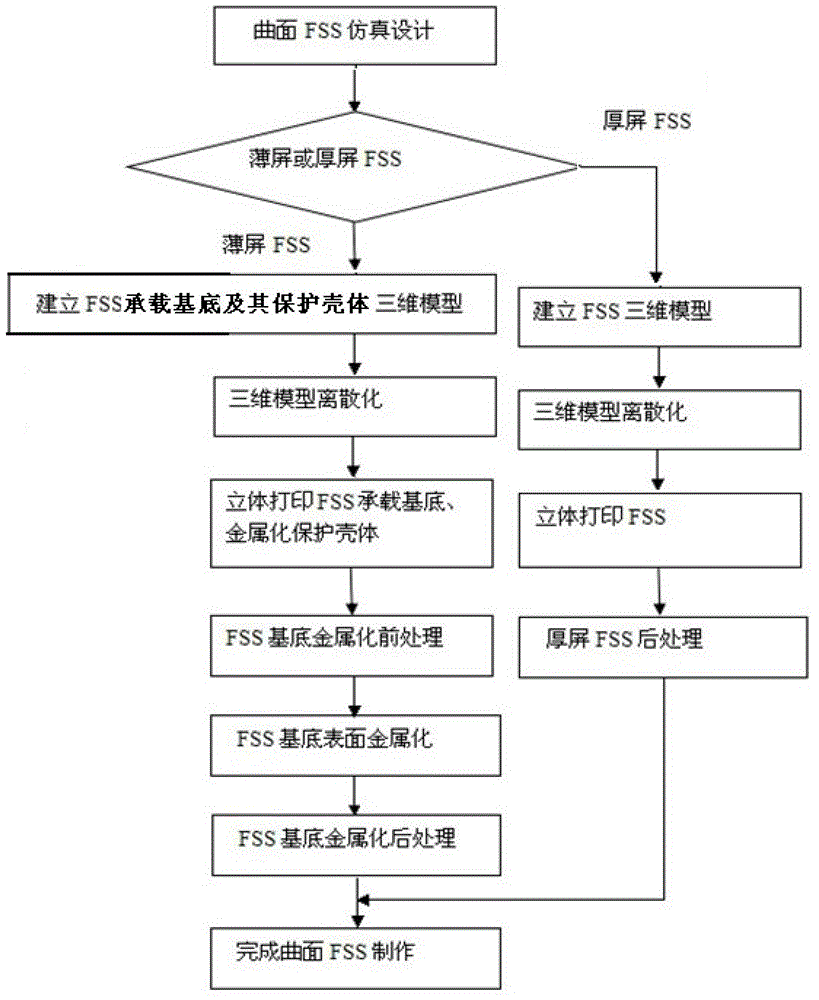

[0032] Such as figure 1 As shown, the steps of the method for making the curved surface FSS by the three-dimensional printing technology of the specific embodiment of the present invention are:

[0033] (1) Surface FSS simulation design: establish the surface FSS and its compound wall model in the professional electromagnetic simulation software;

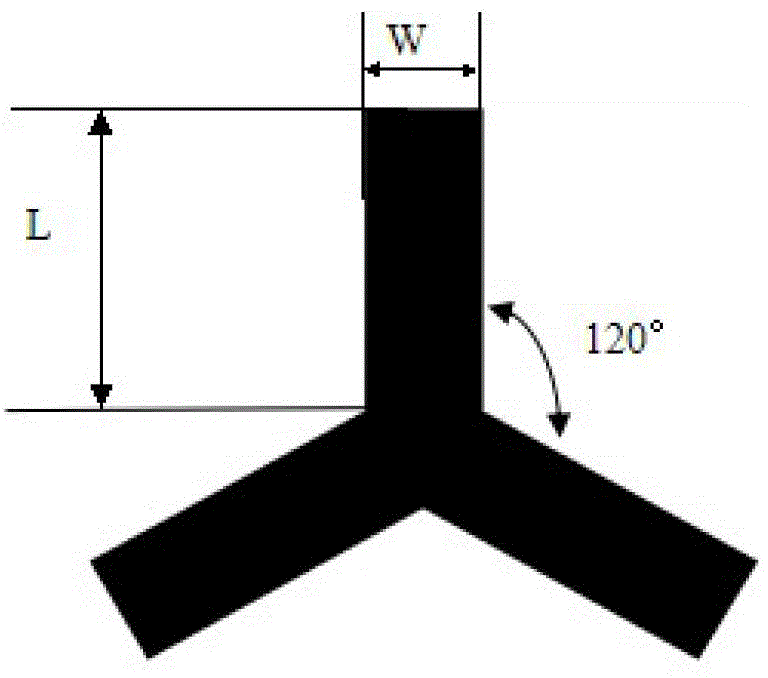

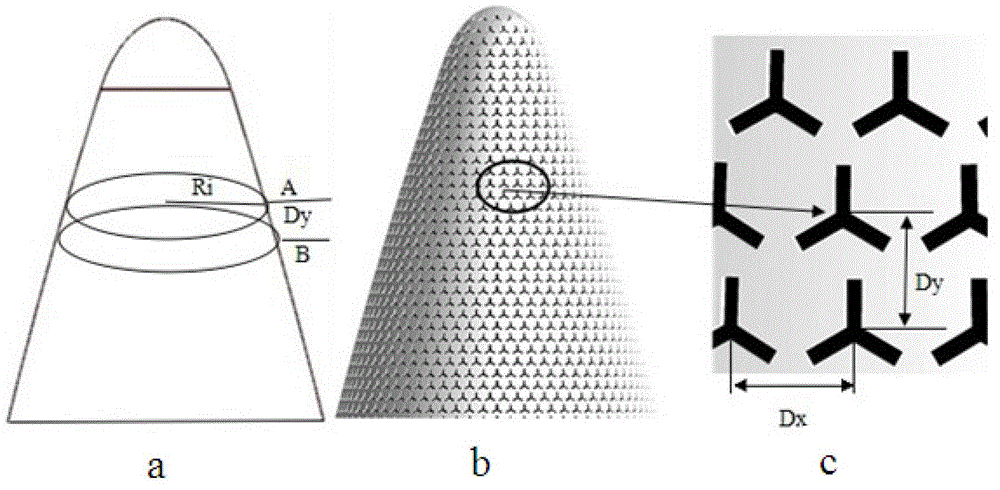

[0034] Considering FSS's resonant bandwidth, angular stability, anti-cross-polarization characteristics, surface quasi-periodic characteristics and other response characteristics and the difficulty of processing, the Y-shaped array is an ideal structural unit for radome, so this The FSS design of the embodiment selects the Y-shaped unit, but structural units such as cross, square, circle and ring can also implement the present invention;

[0035] In the established model, accurately input the electrical parameters of each layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com