Embossing preparation process of wood for solid-wood doors and windows

A preparation process and technology for doors and windows, applied in the field of wood embossing preparation technology for solid wood doors and windows, can solve the problems of low product qualification rate, easy product deformation, large cross-section ratio, etc., and achieve high surface hardness and structural performance, excellent dimensional stability. , high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

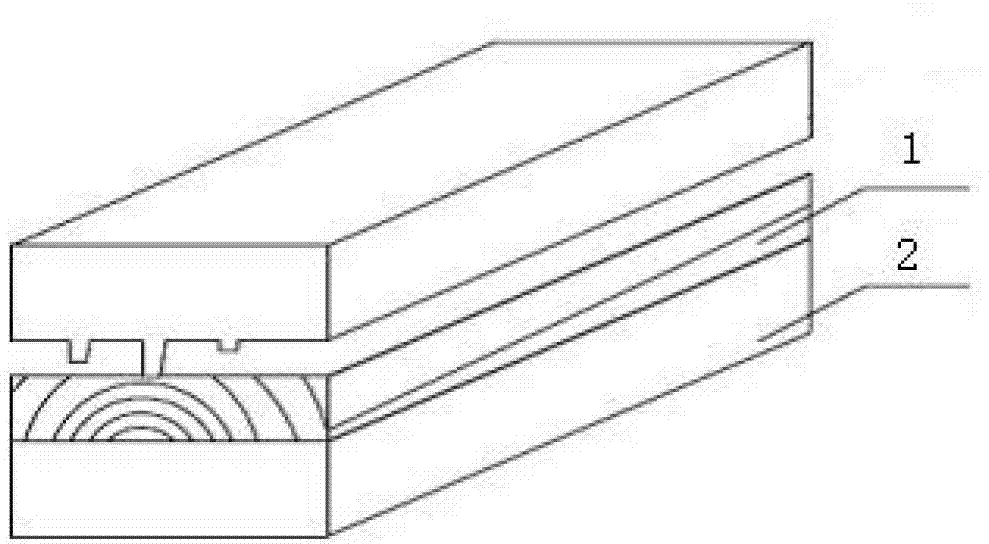

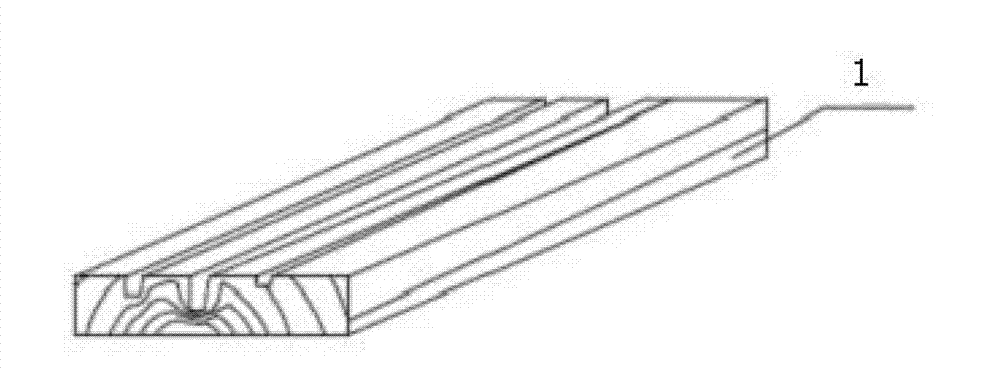

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0018] see figure 1 and figure 2 , the embodiment of the present invention includes: a kind of wood embossing preparation process for solid wood doors and windows, the steps of the processing method include:

[0019] First, the size of the material is processed; the log is sawed into the base material according to the size of the material;

[0020] Second, the material is softened by heat and humidity; soak the substrate in hot water at 50°C~80°C for 1~2 days, or add a small amount of alkaline substances such as sodium hydroxide to the hot water to keep the pH of the hot water at 8 In the range of -9.5, to shorten the soaking time, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com