Air passage ring cutting tool for pantograph pan

A technology of pantograph slides and air passages, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of low product qualification rate and inconsistent depth of fine grooves, etc., to ensure safe operation and accurate tool feeding Quantity control, to achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

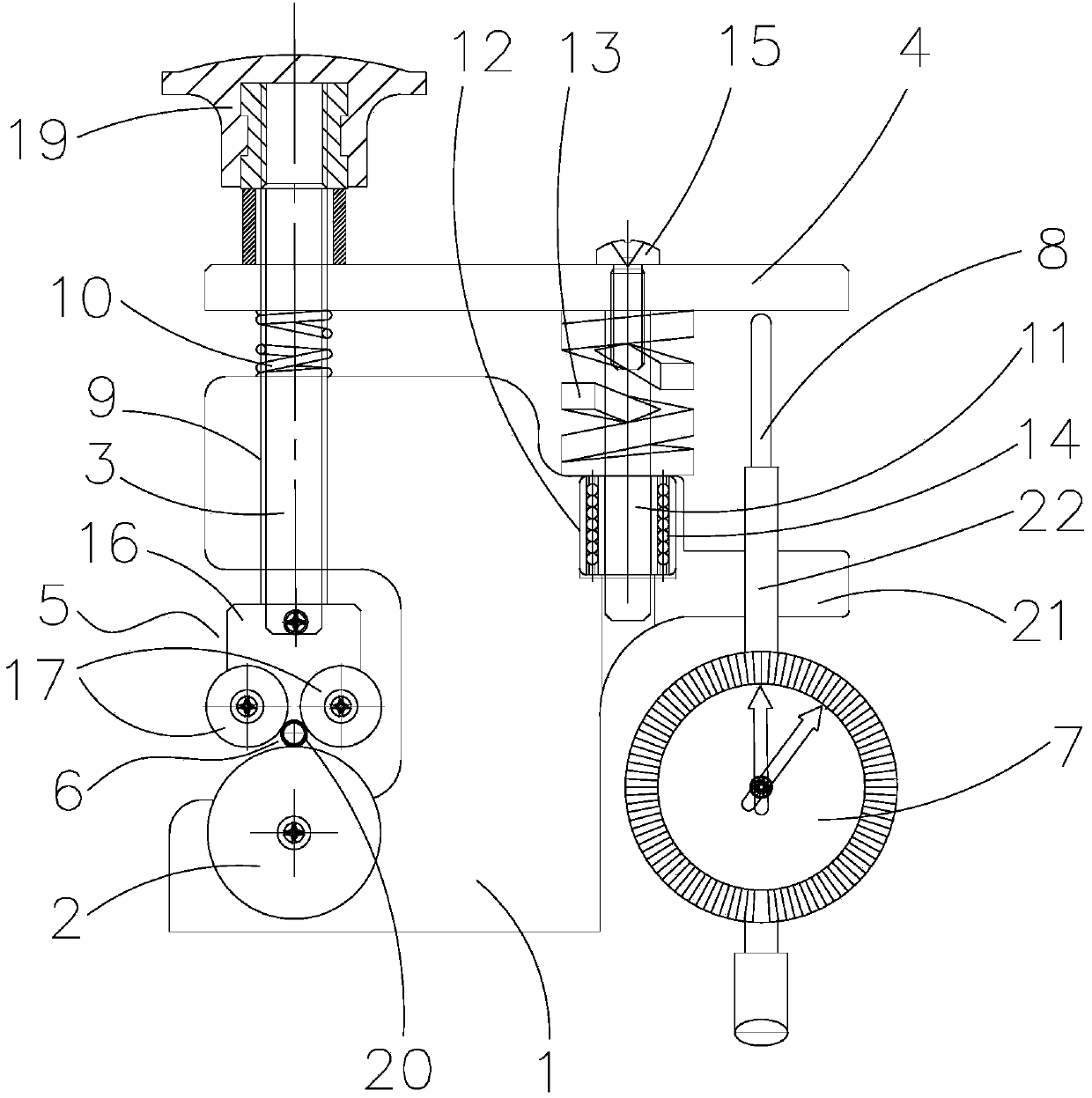

[0032] The pantograph slide airway circumcision tool provided by the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] Such as figure 1 As shown, the pantograph slide airway circumcision tool provided by the specific embodiment of the present invention includes a bracket 1, a cutting control rod 3, a dial indicator 7 and a transmission member 4, specifically,

[0034] On the support 1, preferably the bottom of the support 1 is rotatably provided with a cutting blade 2 for forming a fine groove on the outer surface of the copper pipe;

[0035] The cutting control rod 3 is arranged on the support 1 to move up and down along the height direction of the support 1, and the end of the cutting control rod 3 facing the cutting blade 2 is provided with an airway clamping mechanism 5, so as to be compatible with the The cutting blade 2 forms an airway circumcision chamber 6;

[0036] The dial indicator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com