Whitening and freckle-removing cream

A whitening and freckle-removing, high-quality technology, applied in the field of skin care products, can solve problems such as effect balance and high price, and achieve the effects of delicate luster, skin whitening, and reasonable compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

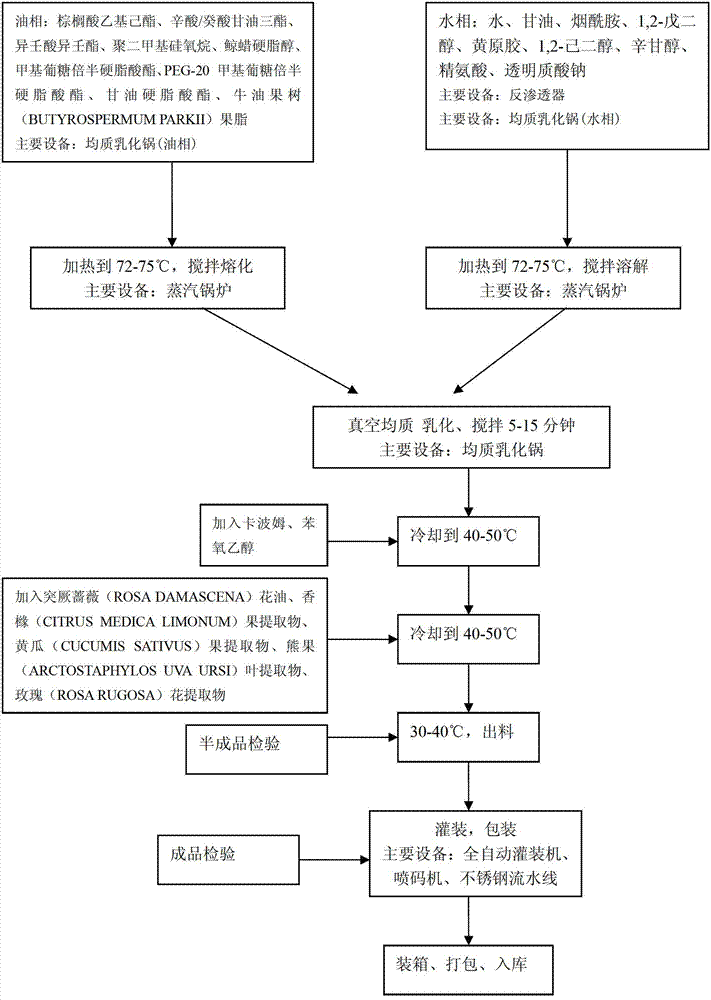

[0022] Such as figure 1 Shown, the preparation method of whitening freckle cream of the present invention comprises the following steps:

[0023] 1. Heat the oil phase material in the oil phase pot of the homogeneous emulsification pot to 72-85 ° C, stir and melt; the oil phase material includes 6-10 parts by mass of ethylhexyl palmitate, 3-5 parts by mass of Caprylic acid / capric triglyceride, 3-7 parts by mass of isononyl isononanoate, 2-4 parts by mass of polydimethylsiloxane, 2-5 parts by mass of cetearyl alcohol, 1.08-1.32 The methyl glucose sesquistearate of mass parts, the PEG-20 methyl glucose sesquistearate of 1.08-1.32 mass parts, the glycerol stearate of 2-5 mass parts and the mass of 0.45-0.55 part of Shea Butter.

[0024] 2. Heat the water phase material in the water phase pot of the homogeneous emulsification pot to 72-85 ° C, stir and dissolve; the water phase material includes 40-50 parts by mass of water, 9-11 parts by mass of glycerin, 2-4 Parts by mass of ...

Embodiment 1

[0032] 1. The oil phase material (ethylhexyl palmitate, caprylic acid / capric triglyceride, isononyl isononanoate, polydimethylsiloxane, cetearyl alcohol, methyl glucose sesquihard Fatty acid ester, PEG-20 methylglucose sesquistearate, glycerol stearate, shea butter (BUTYROSPERMUM PARKII) fruit butter) in the oil phase pot of the homogeneous emulsification pot, heated to 72 ° C, stirred and melted . Wherein the ratio of each component is: 10%, 3%, 5%, 3%, 3%, 1.32%, 1.32%, 3%, 0.55%.

[0033] 2. Mix the aqueous phase materials (water, glycerin, nicotinamide, 1,2-pentanediol, xanthan gum, 1,2-hexanediol, caprylyl glycol, arginine, sodium hyaluronate) in a homogeneous Heat the water phase pot of the emulsification pot to 72°C and stir to dissolve. Wherein the ratio of each component is: 45%, 11%, 4%, 4%, 0.22%, 0.22%, 0.3%, 0.3%, 0.01%.

[0034] 3. Under stirring, slowly pump the oil phase material into the water phase, and emulsify in vacuum for 10 minutes.

[0035] 4. Turn ...

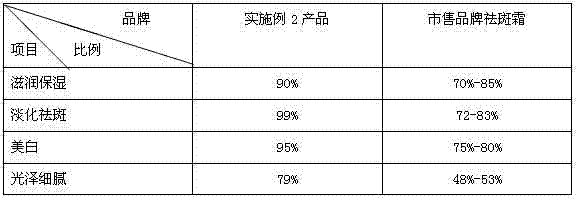

Embodiment 2

[0041] 1. The oil phase material (ethylhexyl palmitate, caprylic acid / capric triglyceride, isononyl isononanoate, polydimethylsiloxane, cetearyl alcohol, methyl glucose sesquihard Fatty acid ester, PEG-20 methyl glucose sesquistearate, glycerol stearate, shea butter (BUTYROSPERMUM PARKII) fruit butter) Heat the oil phase pot of the homogeneous emulsification pot to 78°C, stir and melt. Wherein the ratio of each component is: 6%, 5%, 7%, 2%, 2%, 1.2%, 1.2%, 2%, 0.5%.

[0042] 2. Mix the aqueous phase materials (water, glycerin, nicotinamide, 1,2-pentanediol, xanthan gum, 1,2-hexanediol, caprylyl glycol, arginine, sodium hyaluronate) in a homogeneous Heat the water phase pot of the emulsification pot to 78°C and stir to dissolve. Wherein the ratio of each component is: 50%, 9%, 3%, 3%, 0.2%, 0.2%, 0.38%, 0.5%, 0.02%.

[0043] 3. Under stirring, slowly pump the oil phase material into the water phase, and emulsify in vacuum for 5 minutes.

[0044] 4. Turn on the cooling water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com