Intermediate film for laminated glasses, and laminated glass

A technology of laminated glass and interlayer film, applied in glass/slag layered products, layered products, synthetic resin layered products, etc., can solve the problems of large infrared heat effect, achieve high visible light transmittance, and improve heat insulation And visible light transmittance, heat insulation and visible light transmittance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

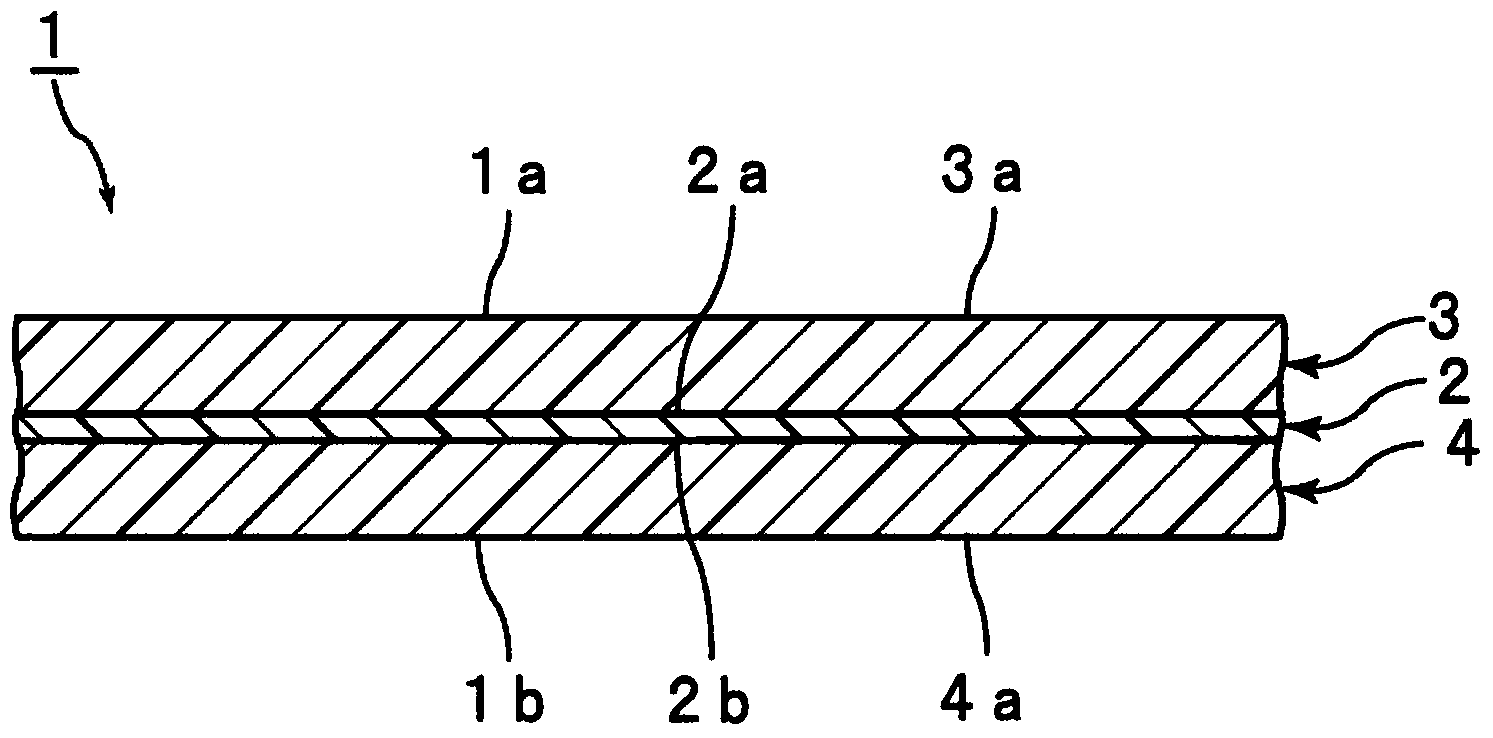

Image

Examples

Embodiment 1

[0177] (1) Production of interlayer film

[0178] 40 parts by weight of plasticizer 1 (triethylene glycol di-2-ethylhexanoate (3GO)), tungsten oxide particles in an amount of 0.030% by weight in 100% by weight of the obtained interlayer film, on the obtained interlayer film Antioxidant (2,6-di-tert-butyl-p-cresol (BHT)) in an amount of 0.80% by weight in 100% by weight, and UV shielding agent 1 in an amount of 0.80% by weight in 100% by weight of the obtained interlayer film ("Tinuvin 326" manufactured by BASF Corporation) was mixed, and after adding the phosphoric acid ester compound as a dispersant, it mixed with the horizontal bead mill, and obtained the dispersion liquid. Among them, the content of the phosphate ester compound is adjusted to 1 / 10 of the content of the tungsten oxide particles.

[0179] The entire amount of the obtained dispersion was added to 100 parts by weight of the polyvinyl butyral resin (PVB1), and it was fully kneaded with a mixing roll to obtain a...

Embodiment 2~7 and comparative example 1~2

[0184]The types and contents of tungsten oxide particles (heat-shielding particles), antioxidants, and ultraviolet shielding agents were set as shown in Table 1 below, except that the same operation as in Example 1 was performed to produce a single interlayer film. Using the obtained interlayer film, the same operation as in Example 1 was performed to produce a laminated glass having an interlayer film. It should be noted that, in Example 7, no antioxidant was used. In Comparative Example 1, no tungsten oxide particles were used. In Comparative Example 2, no ultraviolet shielding agent was used.

Embodiment 8

[0186] (1) Production of heat insulation layer

[0187] Plasticizer 1 (triethylene glycol di-2-ethylhexanoate (3GO)) 60 parts by weight, tungsten oxide particles in an amount of 0.030% by weight in 100% by weight of the obtained intermediate film, and tungsten oxide particles in the obtained intermediate film Antioxidant (2,6-di-tert-butyl-p-cresol (BHT)) was mixed in an amount of 0.80% by weight in 100% by weight of the film, and then a phosphoric acid ester compound was added as a dispersant, and then a horizontal bead mill was used to machine for mixing to obtain a dispersion. Among them, the content of the phosphate ester compound is adjusted to 1 / 10 of the content of the tungsten oxide particles.

[0188] The entire amount of the obtained dispersion was added to 100 parts by weight of polyvinyl butyral resin (PVB2), and it was fully kneaded with a mixing roll to obtain a composition for a heat-shielding layer.

[0189] (2) Production of UV shielding layer

[0190] 40 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com