Copper zinc tin sulfide (CZTS) flexible solar cell and preparation method thereof

A flexible solar cell and flexible substrate technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of low efficiency of CZTS flexible solar cells and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

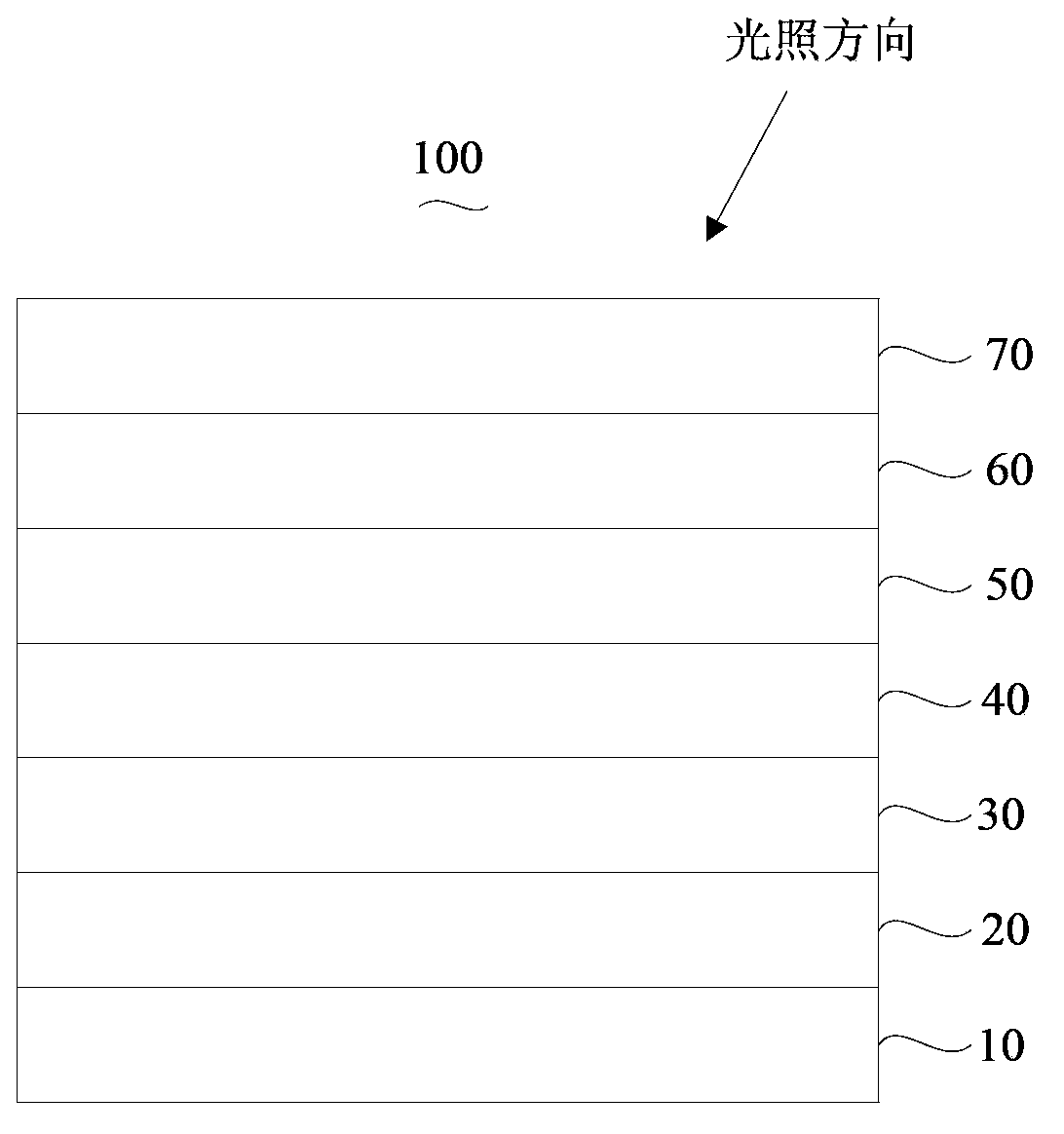

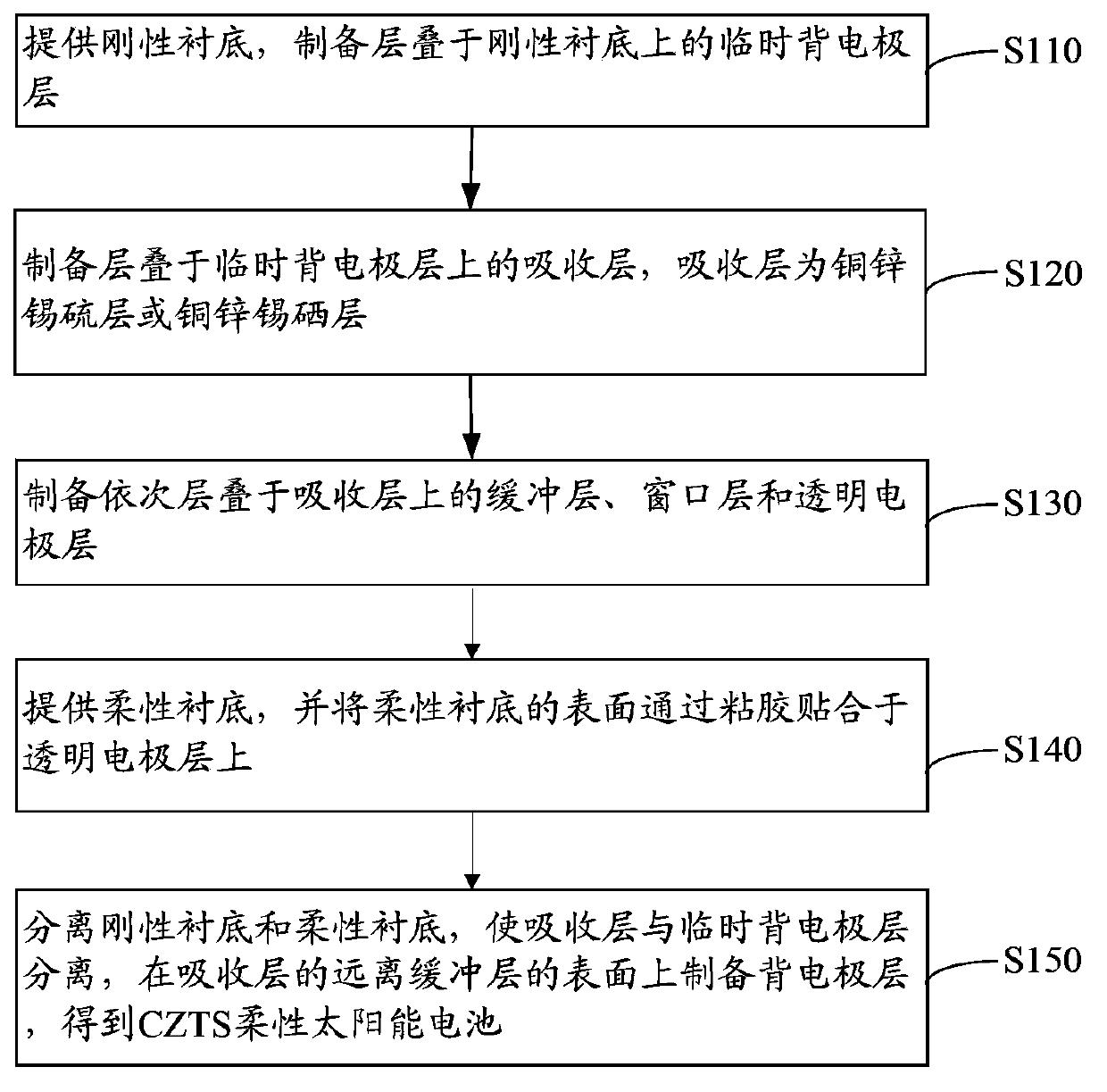

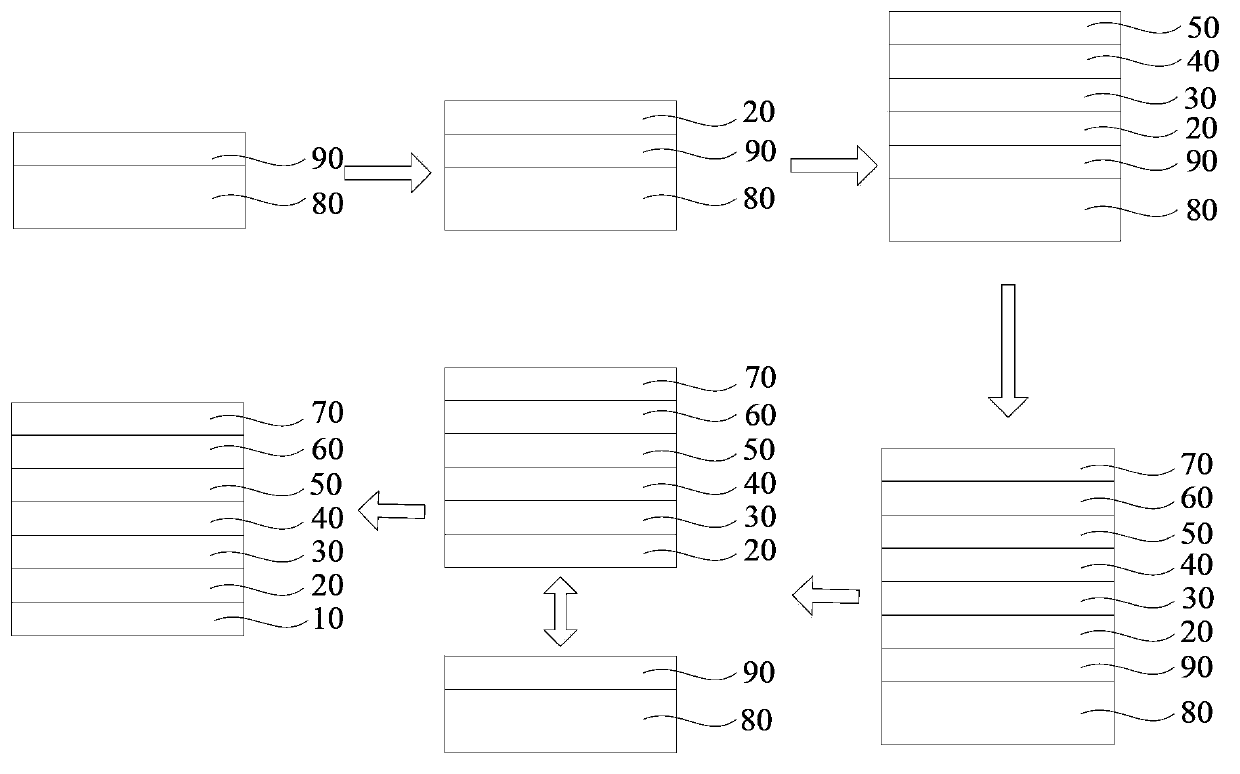

[0044] see figure 2 , A method for preparing a CZTS flexible solar cell in an embodiment includes the following steps S110 to S150.

[0045] Step S110: providing a rigid substrate, and preparing a temporary back electrode layer stacked on the rigid substrate.

[0046] Please also see image 3 , the rigid substrate 80 is preferably soda lime glass. After the rigid substrate 80 is cleaned and dried, molybdenum or aluminum is sputtered onto the clean and dry rigid substrate 80 by sputtering to form a temporary back electrode layer 90 stacked on the rigid substrate 80 .

[0047] The thickness of the temporary back electrode layer 90 is 800 nm.

[0048] Step S120: Prepare an absorbing layer stacked on the temporary back electrode layer, the absorbing layer is a copper zinc tin sulfur layer or a copper zinc tin selenium layer.

[0049] The absorption layer 20 is a copper zinc tin sulfur layer or a copper zinc tin selenium layer. The step of preparing the absorption layer 20 in...

Embodiment 1

[0092] Preparation of CZTS flexible solar cells

[0093] 1. Preparation of copper zinc tin selenium layer by co-evaporation method

[0094] 1. Preparation of copper zinc tin selenium thin film precursor

[0095] Soda-lime glass is used as a rigid substrate, and a temporary back electrode layer with a thickness of 800nm is plated on the rigid substrate. The rigid substrate coated with a temporary back electrode layer is placed on the MBE sample stage, so that the temporary back electrode layer faces For the evaporation source furnace, turn on the rotary switch of the sample stage, and set the temperatures of the Cu source furnace, ZnSe source furnace, Sn source furnace, Se source furnace and sample stage to 1210°C, 765°C, 1140°C, 210°C, and 200°C, respectively. Open Cu source furnace baffle plate, ZnSe source furnace baffle plate, Sn source furnace baffle plate and Se source furnace baffle plate, vapor deposition for 720 seconds, obtain copper zinc tin selenium thin film pre...

Embodiment 2

[0118] Preparation of CZTS flexible solar cells

[0119] 1. Preparation of copper-zinc-tin-sulfur thin films by co-sputtering

[0120] 1. Preparation of CuZnSnS thin film precursor

[0121] Soda-lime glass is used as a rigid substrate, and a temporary back electrode layer with a thickness of 800nm is plated on the rigid substrate. The rigid substrate coated with a temporary back electrode layer is placed on the magnetron sputtering sample stage, so that the temporary back electrode layer The electrode layer faces the substrate baffle, turn on the rotary switch of the sample stage, set the power of Cu target, ZnS target and SnS2 target to 60w, 75w and 70w respectively, and open the Cu target baffle, ZnS target baffle and SnS2 target at the same time. 2 The target baffle was sputtered for 1 hour to obtain a copper-zinc-tin-sulfur thin film precursor with a composition ratio of Cu:Zn:Sn:S=1.8:1.1:1.3:3.9 and a thickness of 1 μm.

[0122] 2. High temperature annealing

[0123...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com