Secondary mirror supporting mechanism capable of quick adjusting

A secondary mirror support and secondary mirror technology, applied in the direction of installation, measuring devices, optics, etc., can solve the problems of low installation and adjustment efficiency, difficult optical system precision adjustment, and long installation and adjustment time, so as to achieve easy precision adjustment work, The installation and adjustment process is simple and the effect of improving the efficiency of installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

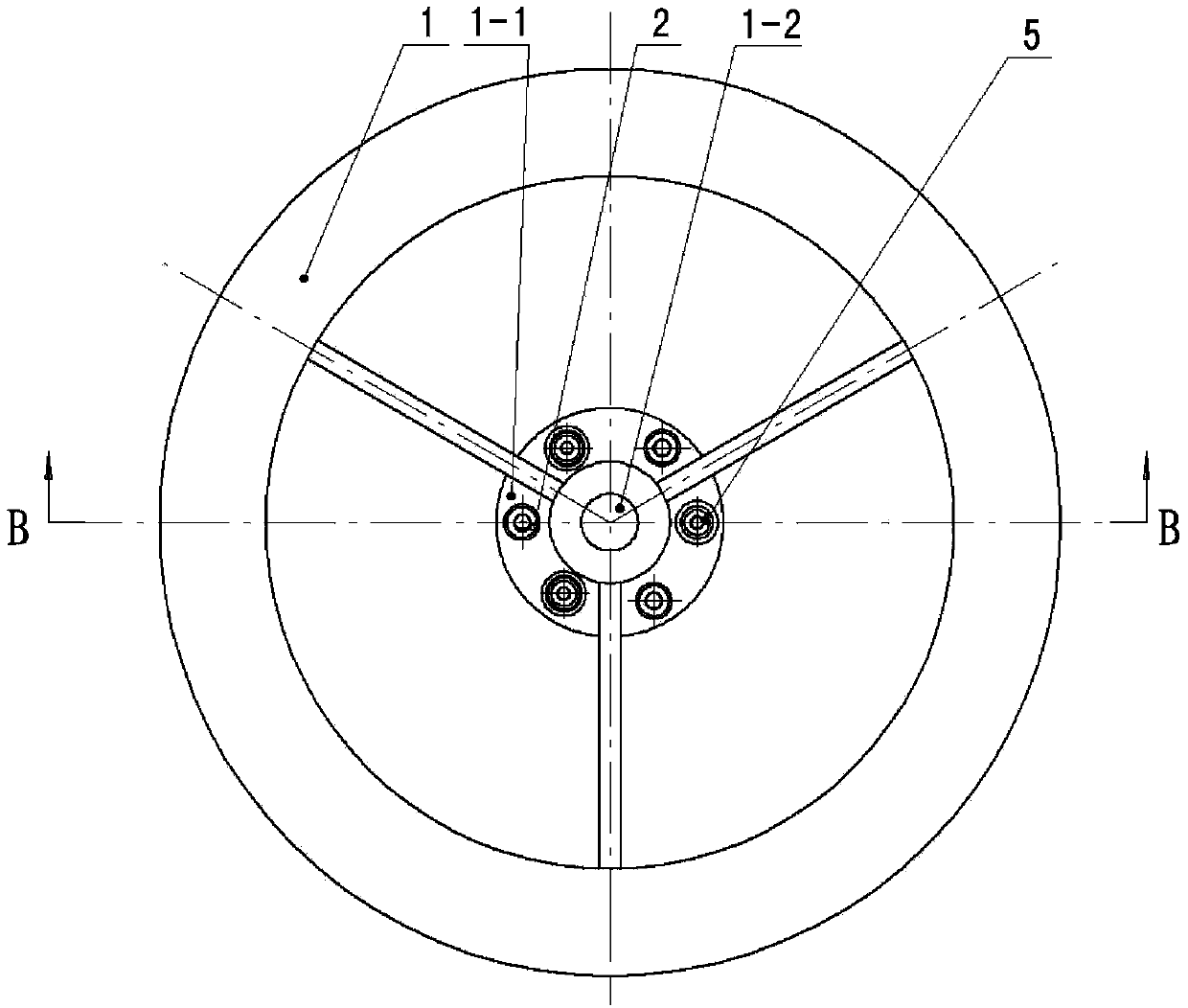

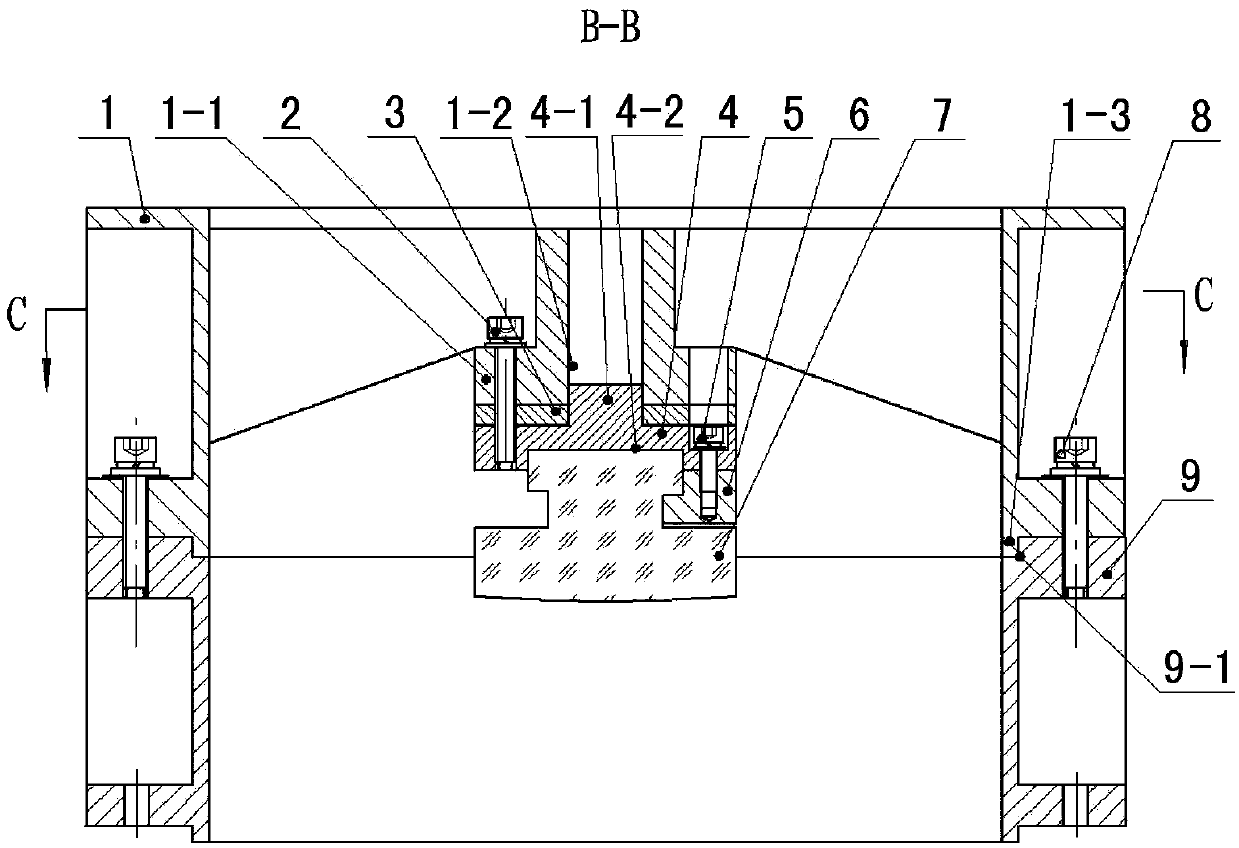

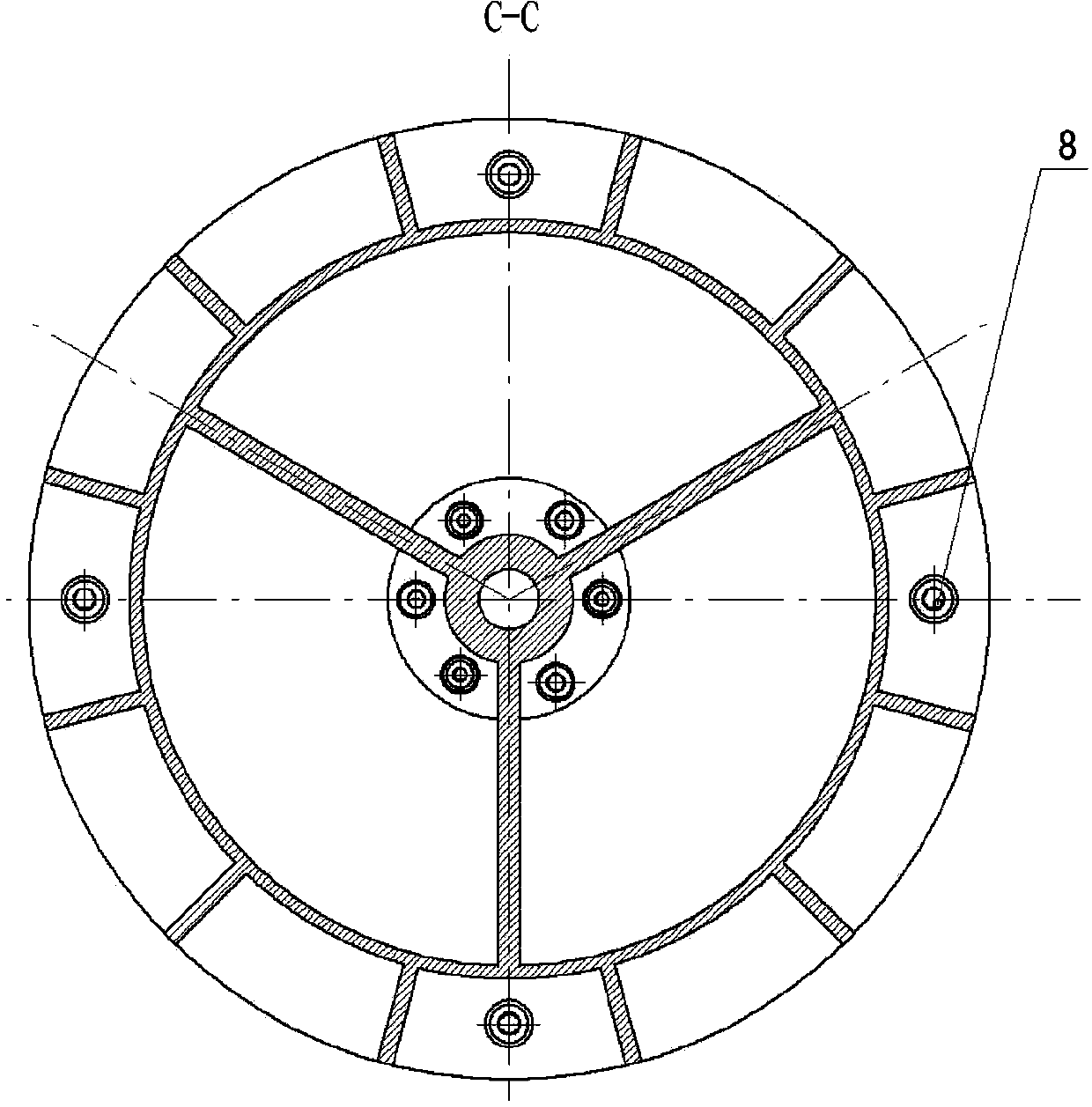

[0021] Such as Figure 4 to Figure 9 As shown, a secondary mirror support mechanism that can be quickly assembled and adjusted includes a secondary lens barrel 10, three first screws 2, a secondary mirror base 4, three second screws 5, three secondary mirror pressure blocks 6, four The third screw 8 , four sliding wedges 11 , four adjusting screw seats 12 , four fourth screws 13 , four adjusting screws 14 , four fixing wedges 15 and connecting cylinder 16 . The secondary mirror seat 4 includes a secondary mirror seat body, a secondary mirror seat boss 4-1 and a secondary mirror seat counterbore 4-2. Secondary lens barrel 10 comprises secondary lens barrel body, secondary lens barrel tripod flange 10-1, center hole 10-2 of tripod flange, secondary lens barrel annular boss 10-3 and secondary lens barrel flange 10 -4. The sliding wedge 11 includes a sliding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com