Thermocouple cold junction compensation type combined socket connector

A technology of cold junction temperature compensation and thermocouple, which is applied in the direction of thermometers, thermometers, electrical components, etc. that use electric/magnetic components that are directly sensitive to heat, and can solve problems such as damage, limited temperature tolerance, and inability to complete temperature measurement. Achieving rugged features, increasing reliability and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

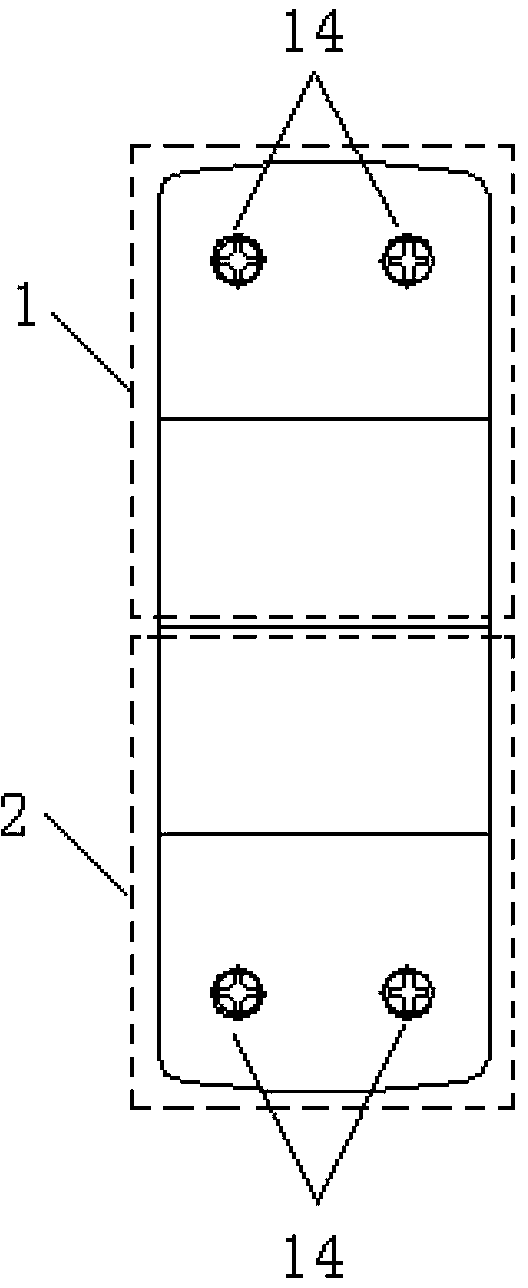

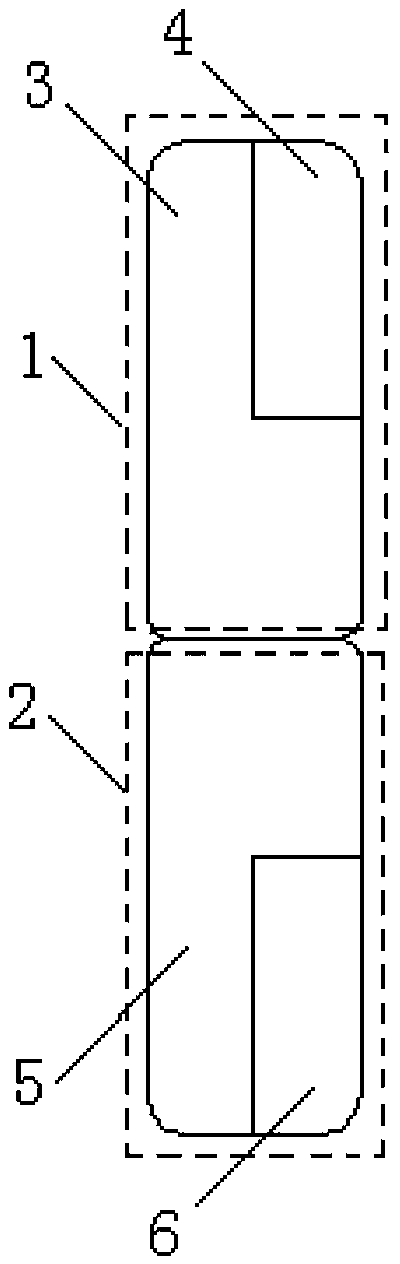

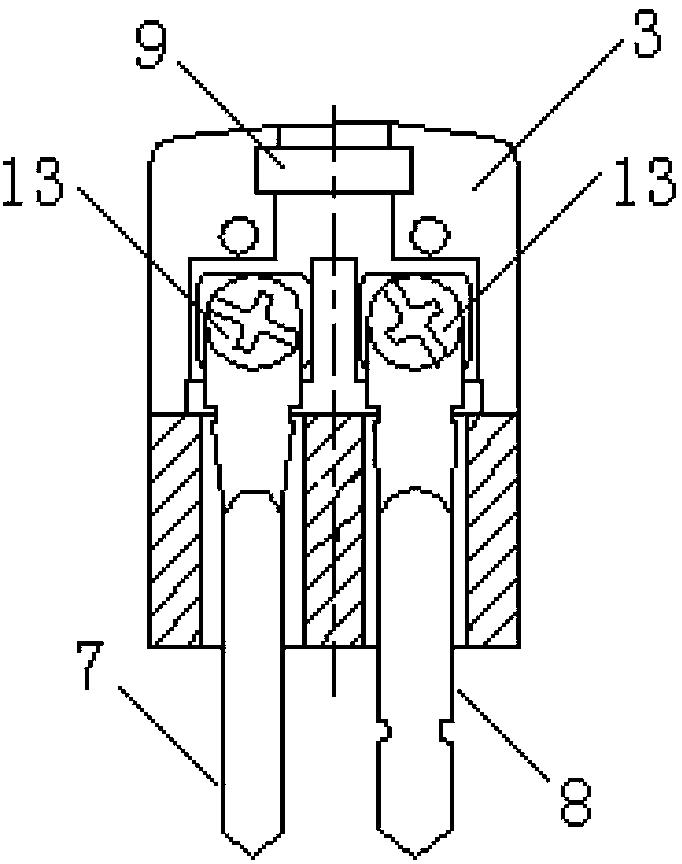

[0031] Such as Figure 1-12 As shown, a thermocouple cold junction temperature compensation combined connector according to the embodiment of the present invention includes a plug-in male 1 and a plug-in female 2; the plug-in male 1 includes a plug-in male bottom cover 3 and a plug-in male Head upper cover 4, male inner core positive pole 7 and male inner core negative pole 8 are arranged side by side in the plug-in male bottom cover 3, and one end of the male inner core positive pole 7 and male inner core negative pole 8 passes through Set screw one 13 is fixedly connected in the plug-in male bottom cover 3, and the other end of the male inner core positive pole 7 and the male inner core negative pole 8 is located outside the plug-in male head 1; the plug-in male bottom cover 3 The tail of the thermocouple connector is provided with a positioning groove 9 for a thermocouple connector; the plug-in male upper cover 4 is located at the rear half of the plug-in male bottom cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com