Co-doped thallium-doped cesium iodide scintillation crystal, preparation method thereof and applications thereof

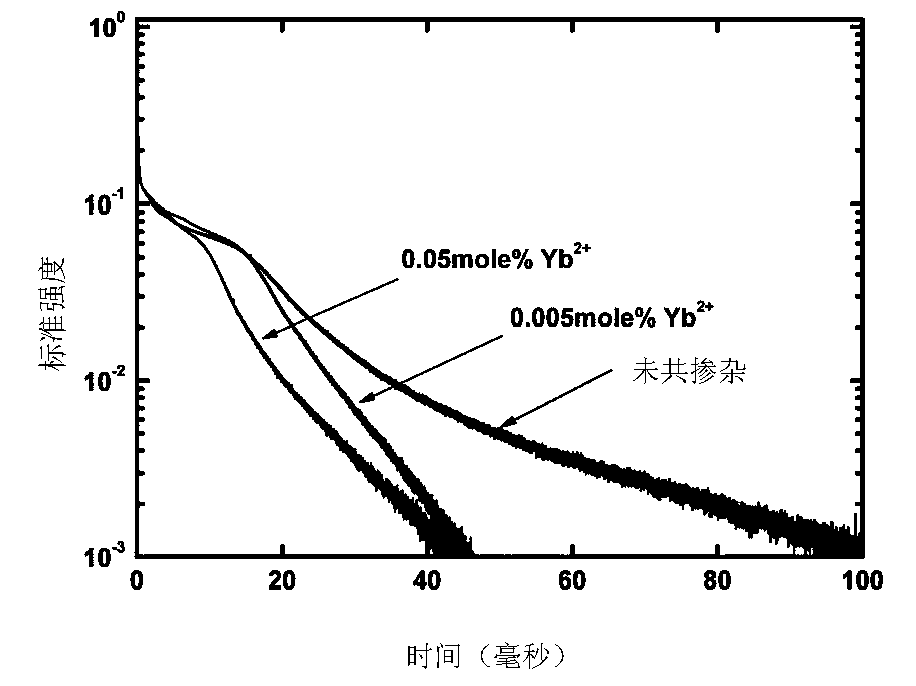

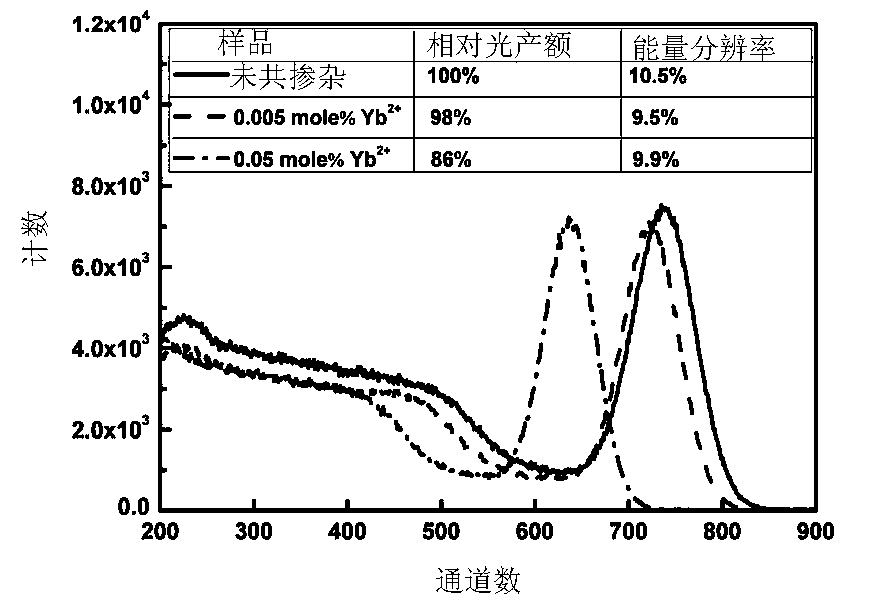

A scintillation crystal and co-doping technology, applied in chemical instruments and methods, applications, crystal growth, etc., can solve the problems of light yield loss, crystal light yield reduction, damage, etc., to maintain light output and energy resolution rate, the effect of suppressing afterglow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: (Cs 0.9985 Tl 0.001 Yb 0.0005 )(I 1.0005 ) growth of single crystal by descent method:

[0029] (1) CsI and TlI with a purity of 99.99%, and YbI with a purity of 99.999% 2 Press (Cs 0.9985 Tl 0.001 Yb 0.0005 )(I 1.0005 ) stoichiometric ratio for proportioning, first weigh CsI518.5g, Tll0.6625g, YbI 2 0.4268g;

[0030] (2) Mix the raw materials thoroughly and put them into a Ф40mm quartz tube, seal the nozzle with acetylene, put the crucible into the ceramic downcomer, and then place the downcomer on the downcomer driving platform;

[0031] (3) Heat the raw materials to a molten state, and keep warm for 8 hours after all the raw materials are melted;

[0032] (4) Lower the quartz crucible at a speed of 1 mm / hour through the lowering mechanism;

[0033] (5) After the crystal grows to a predetermined size, disconnect the power and take out the crystal. After cutting, grinding and polishing, the crystal is processed into a crystal sample with a dia...

Embodiment 2

[0035] Embodiment 2: (Cs 0.9985 Tl 0.001 Yb 0.0005 )(I 0.9995 Br 0.001 ) growth of single crystal by descent method:

[0036] (1) CsI and Tll with a purity of 99.99%, and YbBr with a purity of 99.999% 2 Press (Cs 0.9985 Tl 0.001 Yb 0.0005 )(I 0.9995 Br 0.001 ) stoichiometric ratio, first weigh CsI518.5g, Tll0.6625g, YbBr 2 0.3328g;

[0037] (2) Mix the raw materials thoroughly and put them into a Ф40mm quartz tube, seal the nozzle with acetylene, put the crucible into the ceramic downcomer, and then place the downcomer on the downcomer driving platform;

[0038] (3) Heat the raw materials to a molten state, and keep warm for 8 hours after all the raw materials are melted;

[0039] (4) Lower the quartz crucible at a speed of 0.6mm / hour through the lowering mechanism;

[0040] (5) After the crystal grows to a predetermined size, disconnect the power and take out the crystal. After cutting, grinding and polishing, the crystal is processed into a crystal sample with ...

Embodiment 3

[0042] Embodiment 3: (Cs 0.998 Tl 0.001 Yb 0.001 )(I 0.999 Cl 0.002 ) growth of single crystal by descent method:

[0043] (1) CsI and Tll with a purity of 99.99%, and YbCl with a purity of 99.999% 2 Press (Cs 0.998 Tl 0.001 Yb 0.001 )(I 0.999 Cl 0.002 ) stoichiometric ratio for proportioning, first weigh CsI518.6g, TlI0.6626g, YbCl 2 0.4879g;

[0044] (2) Mix the raw materials thoroughly and put them into a Ф40mm quartz tube, seal the nozzle with acetylene, put the crucible into the ceramic downcomer, and then place the downcomer on the downcomer driving platform;

[0045] (3) Heat the raw materials to a molten state, and keep warm for 8 hours after all the raw materials are melted;

[0046] (4) Lower the quartz crucible at a speed of 2 mm / hour through the lowering mechanism;

[0047] (5) After the crystal grows to a predetermined size, disconnect the power and take out the crystal. After cutting, grinding and polishing, the crystal is processed into a crystal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com