Method for low temperature extraction of volatile fragrance components of natural plants

A technology of fragrance components and natural plants, applied in the directions of essential oils/spices, fat production, etc., can solve the problems of limited application scope of natural plant extracts and limited application of natural plants, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

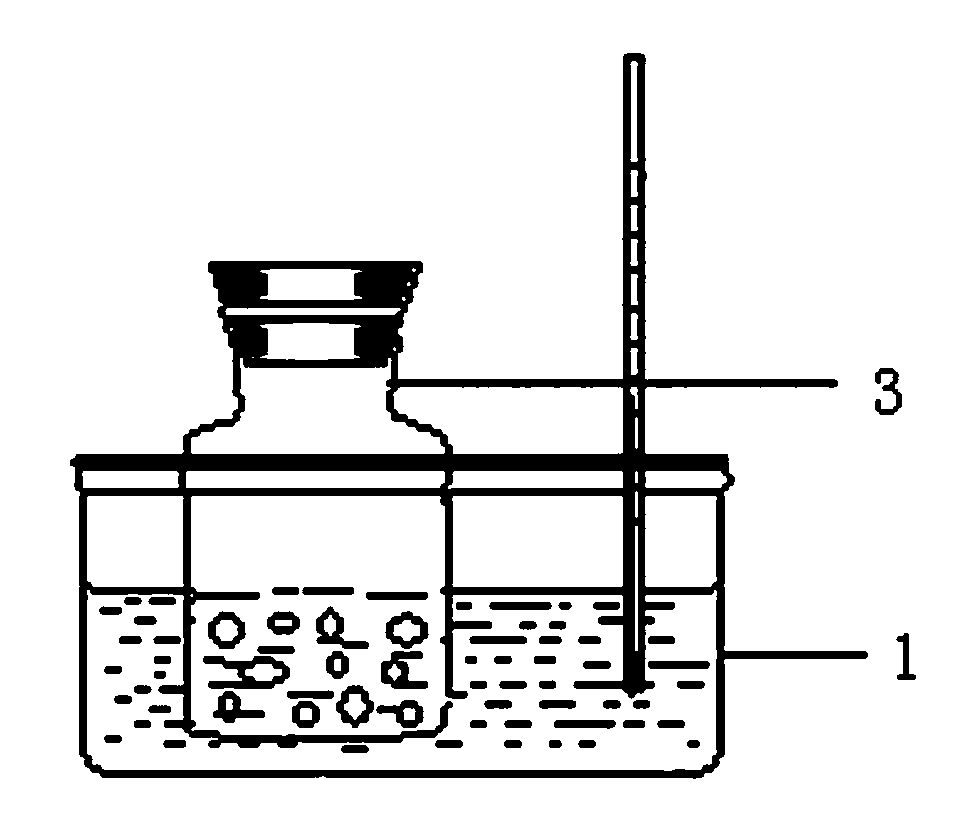

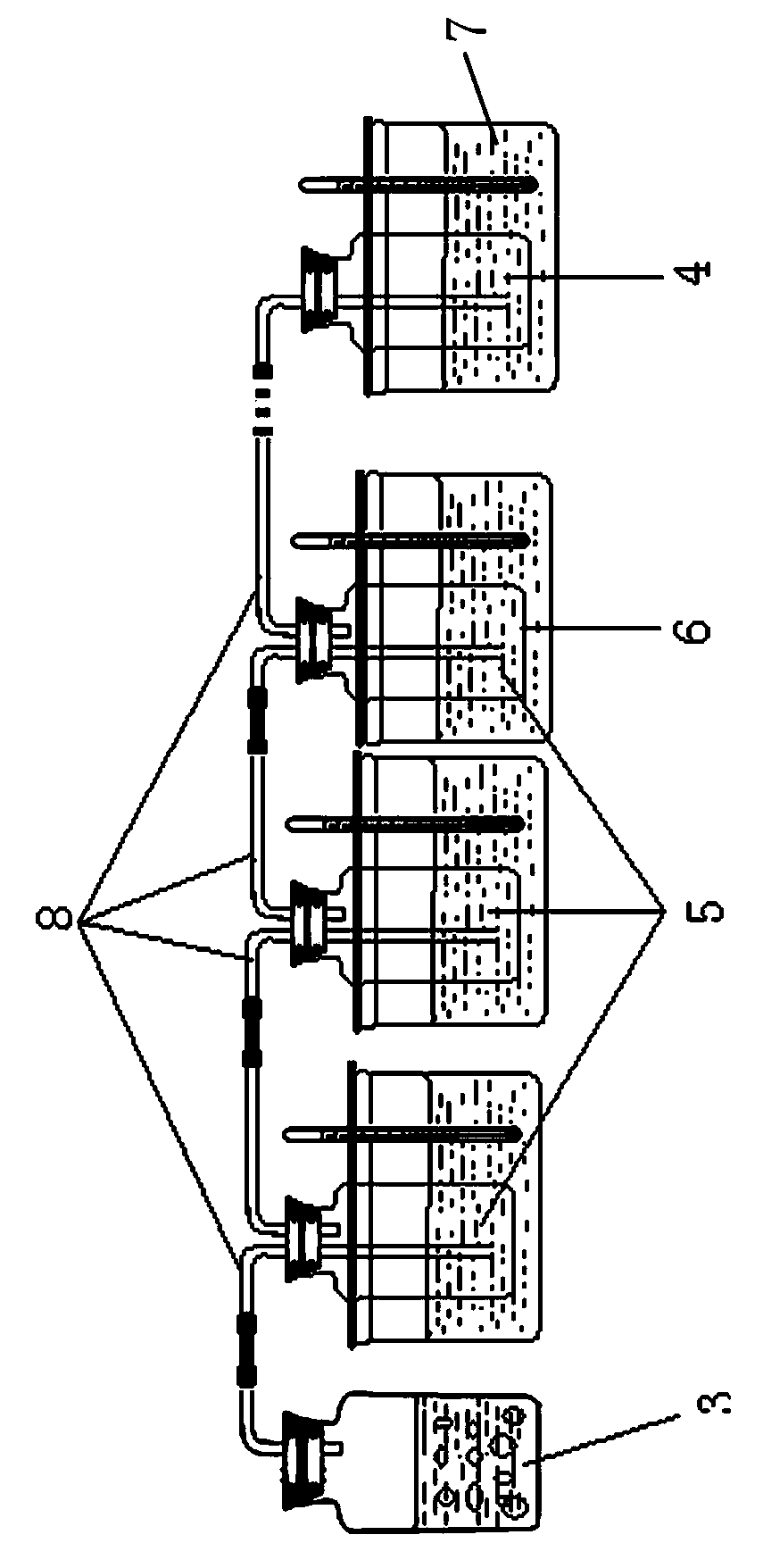

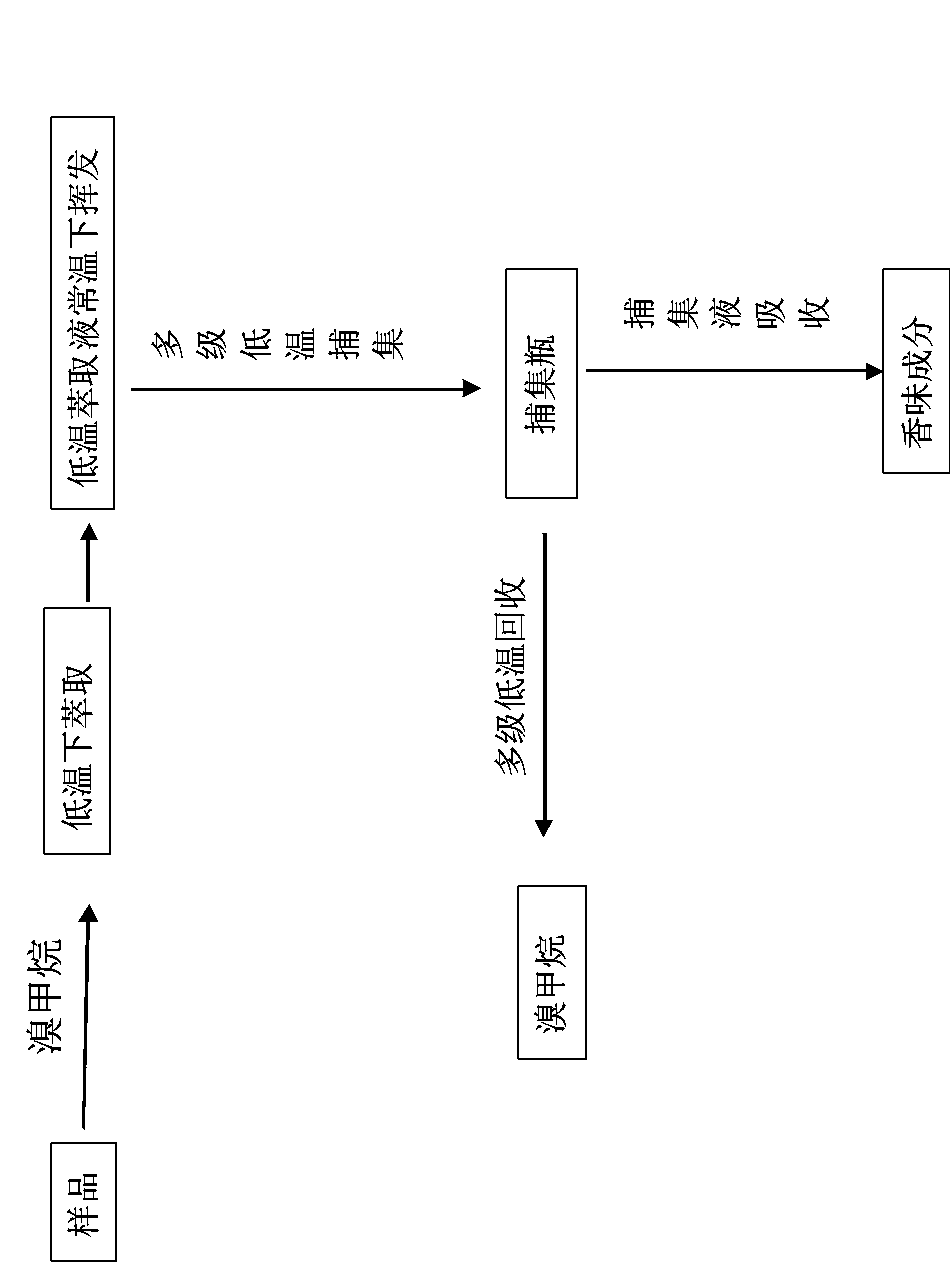

[0022] Example 1. First, 20 g of tea leaves to be extracted and 100 g of methyl bromide (CH3Br) were put into the material bottle 3 and sealed, cooled to a low temperature of -10°C, and extracted at low temperature for 12 hours to obtain an extract. Then the extracted material bottle 3 is taken out from the cooling box 1, and the pipeline 8 is connected. The extract evaporates rapidly at normal temperature, and passes through three trapping bottles 6 connected in series successively. The trapping liquid of the three trapping bottles 6 is pure water. The extracted active ingredients of the tea leaves are absorbed by the trapping liquid 5 . Methyl bromide (CH3Br)4 is finally recovered to the fully cooled recovery bottle 7 for recycling. The recovery liquid in the low-temperature extractant recovery bottle 4 is a mixture of ethanol, ether, and carbon disulfide, and the mixing ratio of ethanol, ether, and carbon disulfide is 60:25:15.

Embodiment 2

[0023] Example 2, firstly put 15g of loquat leaf powder and 80g of methyl bromide (CH3Br) into the material bottle 3 and seal it, cool to a low temperature of -5°C, and extract at low temperature for 11 hours to obtain an extract. Then the extracted material bottle 3 is connected to the pipeline 8, taken out from the cooling box 1, the extract evaporates rapidly at normal temperature, and passes through three trapping bottles 6 in series successively, and the trapping liquid of the three trapping bottles 6 is pure water. The extracted active ingredients of the loquat leaves are absorbed by the trapping solution 5 . Methyl bromide (CH3Br)4 is finally recovered to the fully cooled recovery bottle 7 for recycling. The recovery liquid in the cryogenic extractant recovery bottle 4 is ethanol.

Embodiment 3

[0024] Example 3: First, 35 g of ginkgo leaf powder and 150 g of low-temperature extractant methyl bromide (CH3Br) were put into the material bottle 3 and tightly capped, cooled to -6°C, and extracted under low-temperature extraction for 14 hours to obtain an extract. Then the extracted material bottle 3 is taken out from the cooling box 1, and the pipeline 8 is connected. The extract evaporates rapidly at normal temperature, and passes through four trapping bottles in series successively. The trapping liquid of the four trapping bottles 6 is water. or pure water. The extracted active ingredients of ginkgo biloba are absorbed by the trapping solution 5 . Methyl bromide (CH3Br)4 is finally recovered to the fully cooled recovery bottle 7 for recycling. The recovery solution in the low-temperature extraction agent recovery bottle 4 is a mixture of ethanol and ether, and the mixing ratio of ethanol and ether is 80:20.

[0025] Embodiment 1 of the present invention differs from E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com