Control method for detection of broken wires of elevator traction rope

A control method and elevator control technology, applied in the field of elevator control, can solve problems such as poor timeliness, large subjective influence, and no automatic real-time monitoring of broken wires, so as to provide safety in use, ensure reliable operation, and reduce maintenance difficulty and labor cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

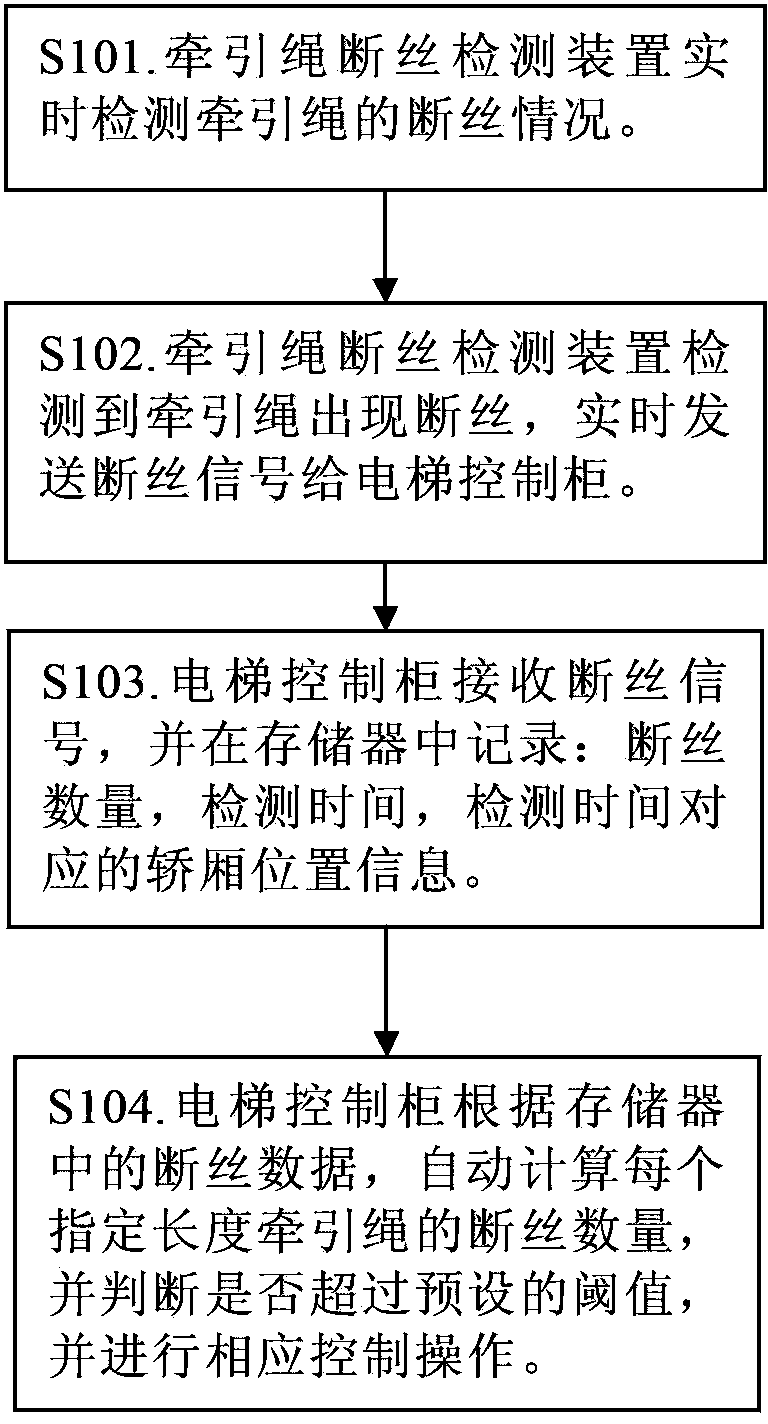

[0016] Such as figure 1 Shown, a kind of control method of elevator traction rope broken wire detection comprises the following steps:

[0017] S101. The wire break detection device of the traction rope detects the wire breakage of the traction rope in real time.

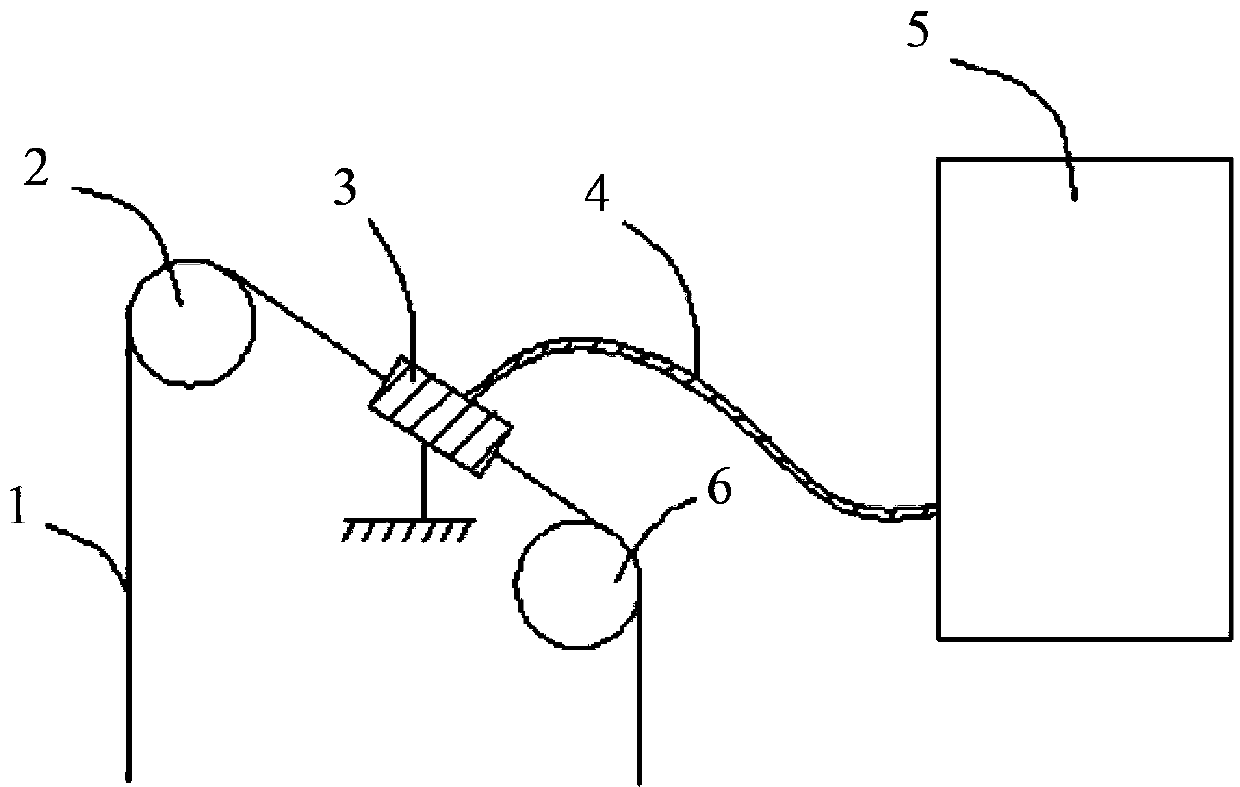

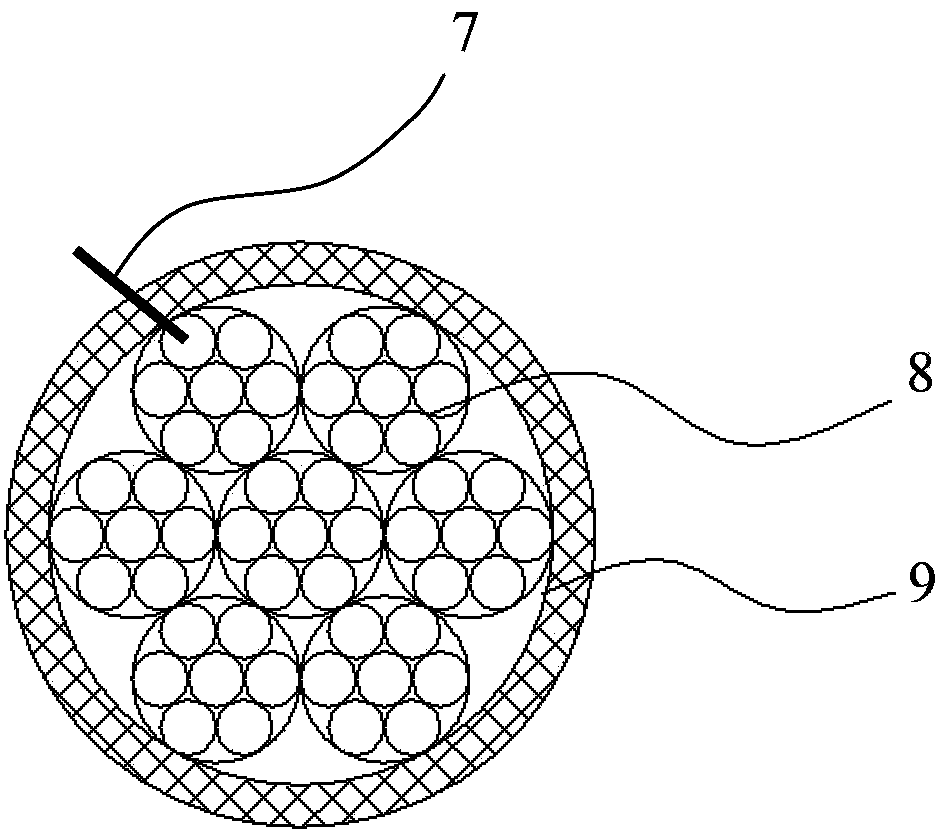

[0018] It should be noted that in this step, the detection device for the broken wire of the traction rope uses an infrared imaging detection device, but the infrared imaging detection device is only a device that can be used, and a magnetic flux detection device can also be used. The traction rope is generally round and adopts a structure in which the outer surface of the steel wire rope is covered with a thermoplastic coating. image 3 As shown): When the steel wire rope 8 inside the traction rope is damaged due to fatigue bending, some steel wires 7 will be broken, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com