Method for continuously extracting active components of Hibiscus taiwanensis by utilizing supercritical carbon dioxide

A technology of carbon dioxide and active ingredients, applied in the direction of solid solvent extraction, etc., to achieve the effects of reducing production costs, simplifying the process, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

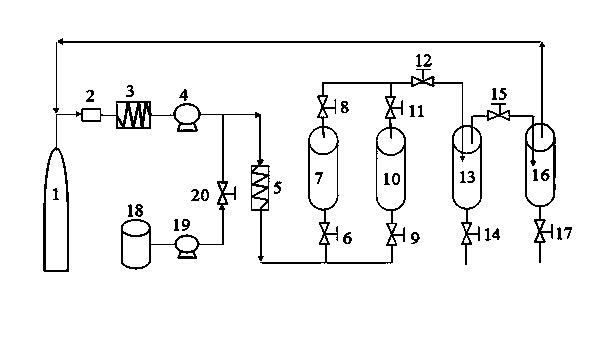

Method used

Image

Examples

Embodiment 1

[0025] Put 2 kg of dried Taiwan hibiscus root powder of about 10 mesh into extraction kettle I7 and extraction kettle II10. Set the extraction pressure to 40MPa, the extraction temperature to 32°C, the temperature of the separation tank I13 to 45°C, the pressure to 8MPa, and the pressure to the separation tank II16 to 4.5Mpa. After static extraction for 1 hour, 95% ethanol was used as entrainer for dynamic extraction for 2 hours, and the dosage of 95% ethanol was 1400ml. The extract was collected and concentrated to obtain 22g of Taiwan mountain hibiscus extract.

Embodiment 2

[0027] Wet 2 kg of 40 mesh Taiwan hibiscus stem powder with 400 ml of 75% ethanol and put it into extraction kettle I7 and extraction kettle II10. Set the extraction pressure to 30MPa, the extraction temperature to 55°C, the temperature of separation tank I13 to 50°C, the pressure to 8MPa, and the pressure to separation tank II16 to 4.5Mpa. After static extraction for 0.5 hours, pump 600ml of entrainer with a concentration of 75% ethanol into the extraction kettle, extract dynamically for 2.5 hours, collect the extract, and concentrate to obtain 25g of Taiwan Mountain Hibiscus extract.

Embodiment 3

[0029] Mix 2kg of dried 100-mesh Taiwan hibiscus leaf powder with 800ml of 50% ethanol and put them into extraction kettle I7 and extraction kettle II10. Set the extraction pressure to 20MPa, the extraction temperature to 75°C, the temperature of separation kettle I13 to 75°C, the pressure to 6MPa, the pressure of separation kettle II16 to 5Mpa, and dynamic extraction for 3 hours. The extract was collected and concentrated to obtain 43g of Taiwan mountain hibiscus extract.

[0030] The following is to observe the supercritical CO 2 Advantages and disadvantages of extraction technology and existing technology (ethanol method).

[0031] Existing technology (extraction by ethanol method): add 2kg of root, stem and leaf powder of Hibiscus taiwanensis, add 20L of 95% ethanol, soak for 2 to 3 days, filter, concentrate the filtrate, soak the filter residue in 20L of 95% ethanol, repeat this process 3 times, the collected filtrate was combined and concentrated to obtain the extract o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com