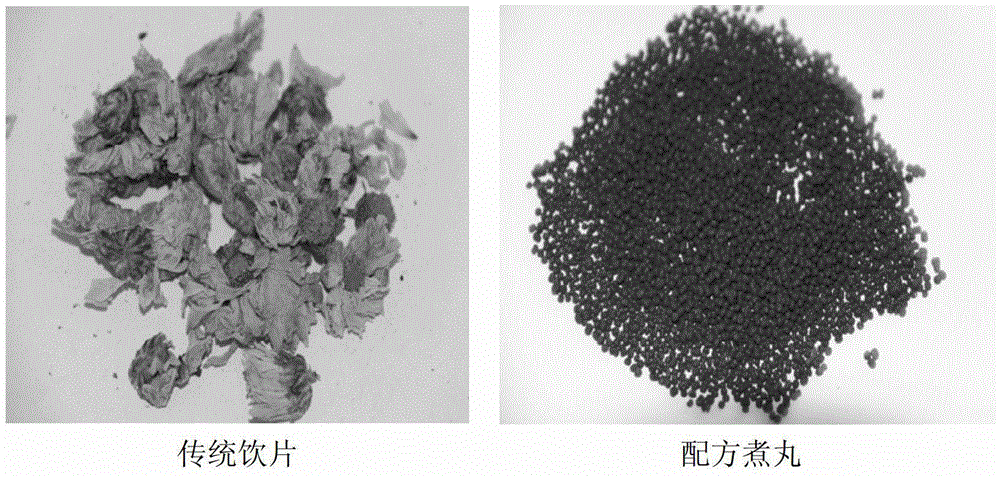

Chrysanthemum decocting pill and preparation process thereof

A preparation process, the technology of chrysanthemum, applied in the direction of medical formula, medical preparations containing active ingredients, pill delivery, etc., can solve the problem of excessive heavy metal Pb and Hg content in chrysanthemum, reduce the efficacy and active ingredients of chrysanthemum, and not to mention the efficacy and curative effect, to achieve good roundness, save medicinal materials, and solve the effect of less manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Clean fresh chrysanthemums after removing impurities, put them into vacuum freeze-drying equipment for pre-freezing, pre-freeze at a temperature of -50 to -80°C for 0.5 to 1 hour, and then vacuumize the system to make the absolute pressure of the system 35 to 65Pa, and then gradually Heating to 30-50°C, sublimation drying for 20-36 hours. The processed chrysanthemums are pulverized and passed through a sieve of 80-100 meshes to obtain medicinal powder.

[0033] Take an appropriate amount of powder (pilot test level: 300g), mix it with water at a weight ratio of 1:0.75 to obtain soft material, granulate (screen aperture 1.0mm), and put the wet particles in a centrifugal ball blasting machine for shot blasting (speed 600rpm, Time 20min), the prepared wet shot was placed in a blast drying oven, and dried at 60°C for 8 hours. Take it out and let it cool at room temperature, sift through a sieve, and take shot balls between No. 1 sieve and No. 2 sieve (that is, 10-24 mesh) ...

Embodiment 2

[0035] Clean the fresh chrysanthemums after removing impurities, put them into vacuum freeze-drying equipment for pre-freezing, pre-freeze at -80°C for 1 hour, then vacuumize the system to make the absolute pressure of the system 60Pa, then gradually heat up to 50°C, sublimation and drying 36h. The treated chrysanthemum is pulverized and passed through an 80-mesh sieve to obtain medicinal powder.

[0036] Take an appropriate amount of powder (pilot test level: 300g), mix it with water at a weight ratio of 1:0.8 to obtain a soft material, granulate (screen aperture 1.0mm), and put the wet particles in a centrifugal ball blasting machine for shot blasting (speed: 600rpm, Time 20min), the prepared wet shot was placed in a blast drying oven, and dried at 60°C for 8 hours. Take it out and let it cool at room temperature, sift through a sieve, and take shot balls between No. 1 sieve and No. 2 sieve (that is, 10-24 mesh) to obtain the chrysanthemum formula boiled balls.

Embodiment 3

[0038] Clean the fresh chrysanthemum after removing impurities, put it into the vacuum freeze-drying equipment for pre-freezing, pre-freeze at -50°C for 0.5h, then vacuumize the system to make the absolute pressure of the system 35Pa, then gradually heat up to 30°C, sublimation Dry for 36h. The treated chrysanthemum is pulverized and passed through a 100-mesh sieve to obtain medicinal powder.

[0039] Take an appropriate amount of medicine powder (pilot test level: 300g), mix it with water at a weight ratio of 1:0.85 to obtain soft material, granulate (screen aperture 1.0mm), and put the wet particles in a centrifugal ball blasting machine for shot blasting (speed: 580rpm, Time 20min), the prepared wet shot was placed in a blast drying oven, and dried at 65°C for 8 hours. Take it out and let it cool at room temperature, sift through a sieve, and take shot balls between No. 1 sieve and No. 2 sieve (that is, 10-24 mesh) to obtain the chrysanthemum formula boiled balls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com