Automatic diamond cutter head welding strength detector

A technology of diamond cutter head and welding strength, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as low detection efficiency, and achieve the effects of high detection efficiency, high detection accuracy and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

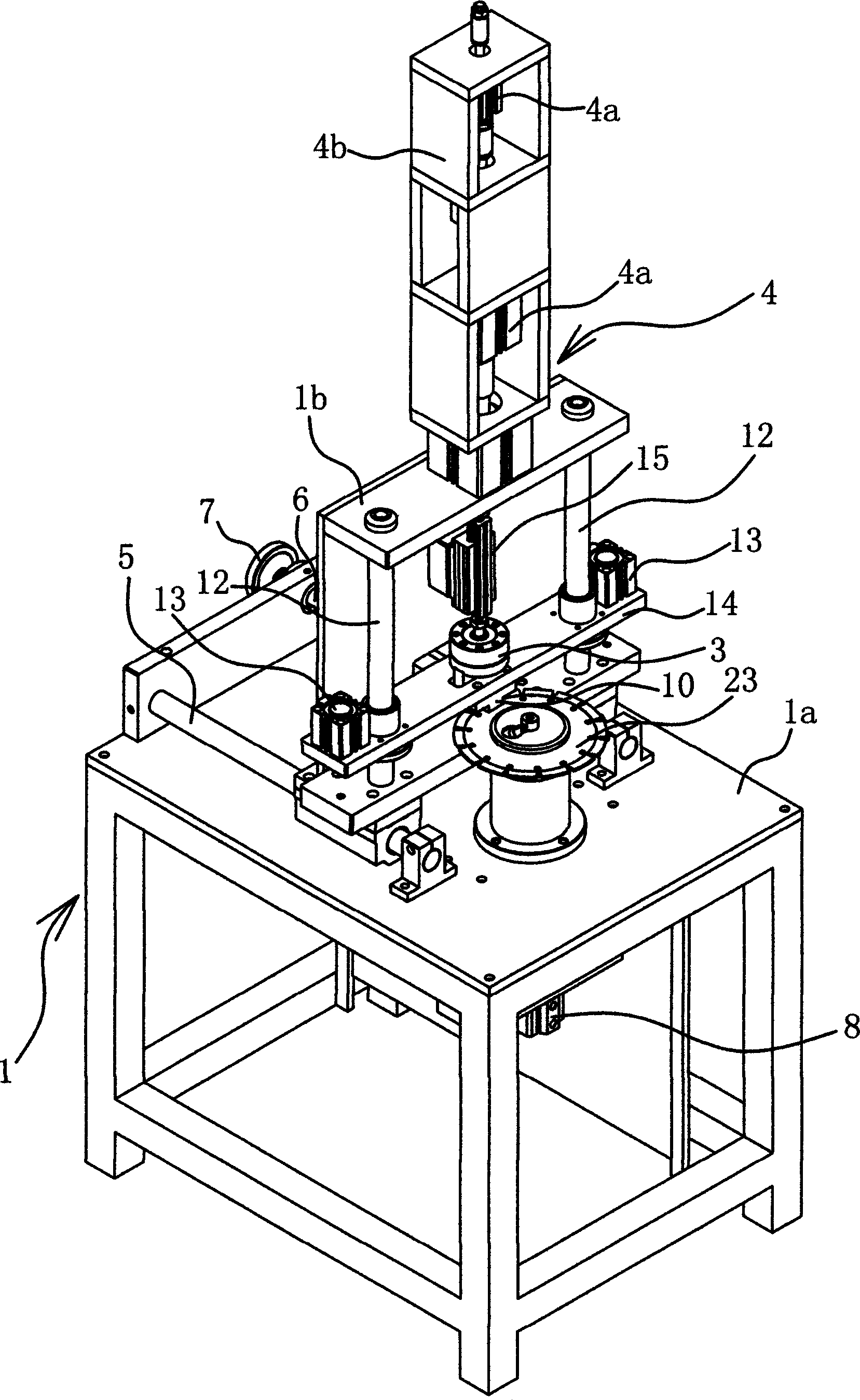

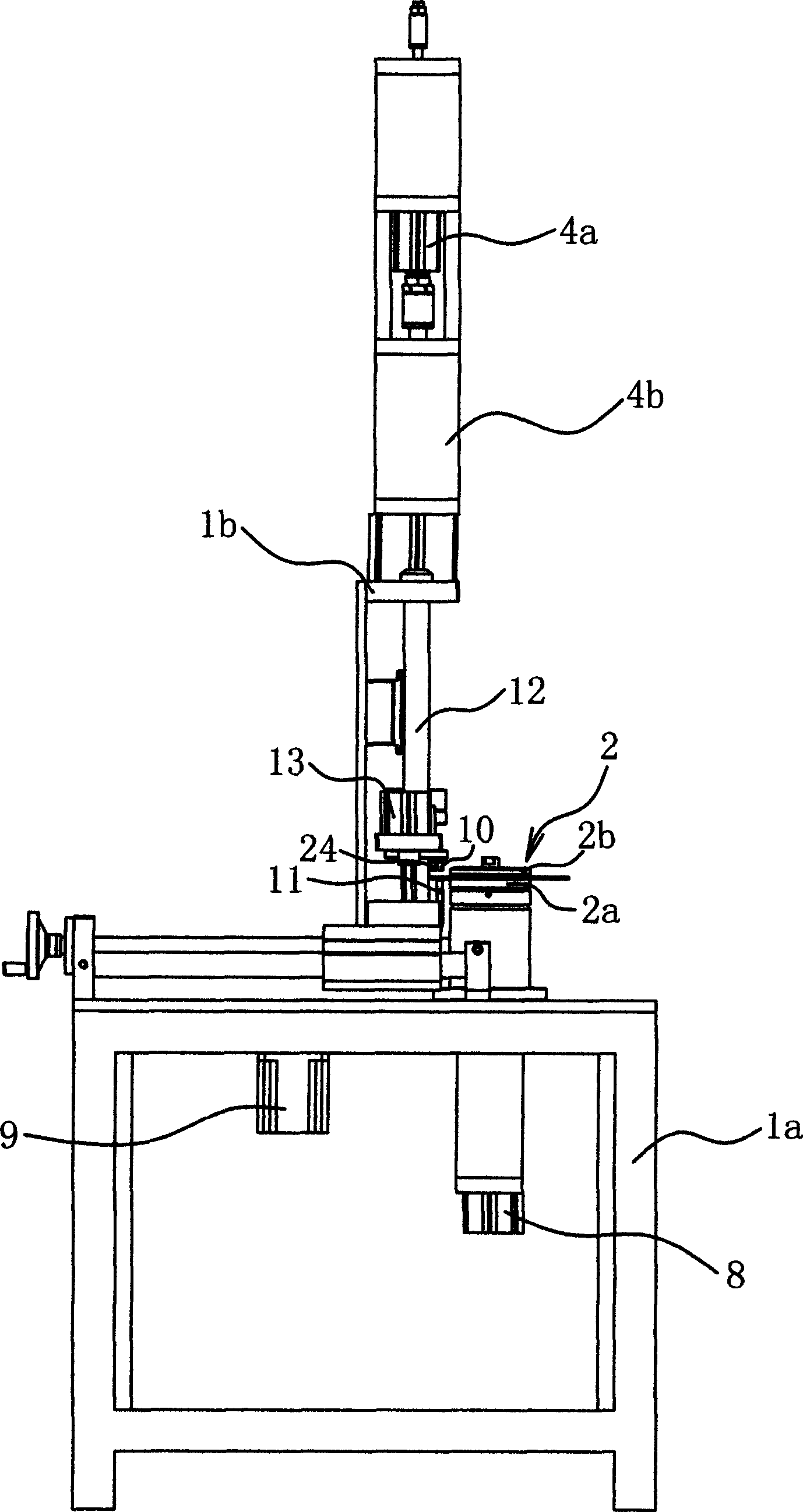

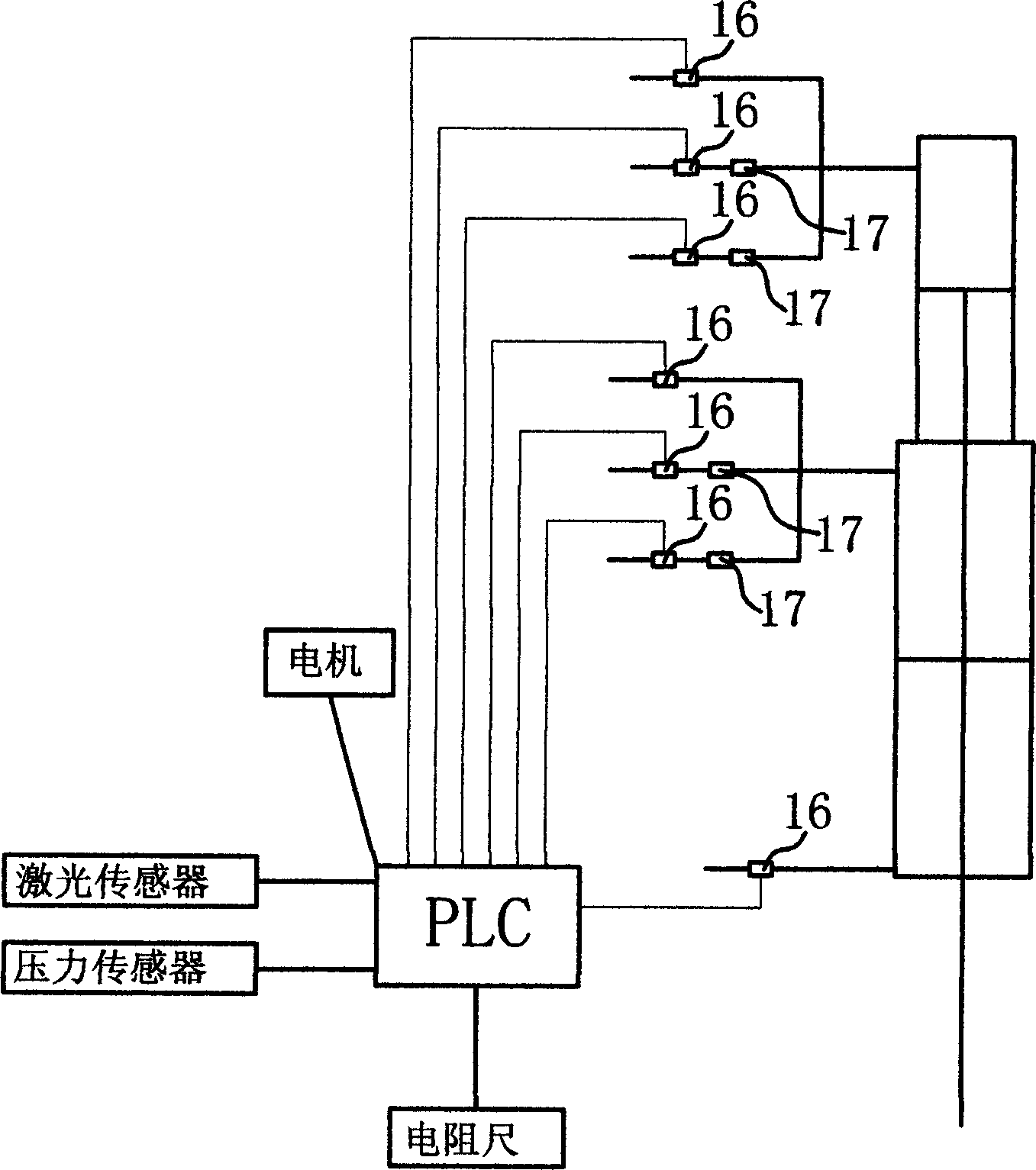

Method used

Image

Examples

Embodiment 2

[0045] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Image 6 As shown, the clamp 2 includes a base plate 2a and a magnet 2c, and the center of the base plate 2a has a positioning protrusion 2e adapted to the center hole of the diamond saw blade 23 . There are several magnet 2c mounting holes distributed circumferentially on the upper surface of the base plate 2a, the magnet 2c is arranged in the magnet 2c mounting hole, a magnetic isolation cover 2d is filled between the magnet 2c and the side wall of the magnet 2c mounting hole, and the magnet 2c is connected to the base plate. 2a Fixed connection. The driving mechanism includes a reduction box and a motor 9, the casing of the motor 9 and the box body of the reduction box are fixed on the movable frame 1b, the base plate 2a is fixedly connected with the output shaft of the reduction box; the rotating shaft of the motor 9 is connected with the input shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com