Drilling head separating floor anchoring drill

A separate, bottom-plate technology, used in earth-moving drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of reducing support efficiency, waste of water resources, affecting bolt support, etc., and achieve improved support Efficiency, speed up construction, reduce the effect of surrounding rock strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

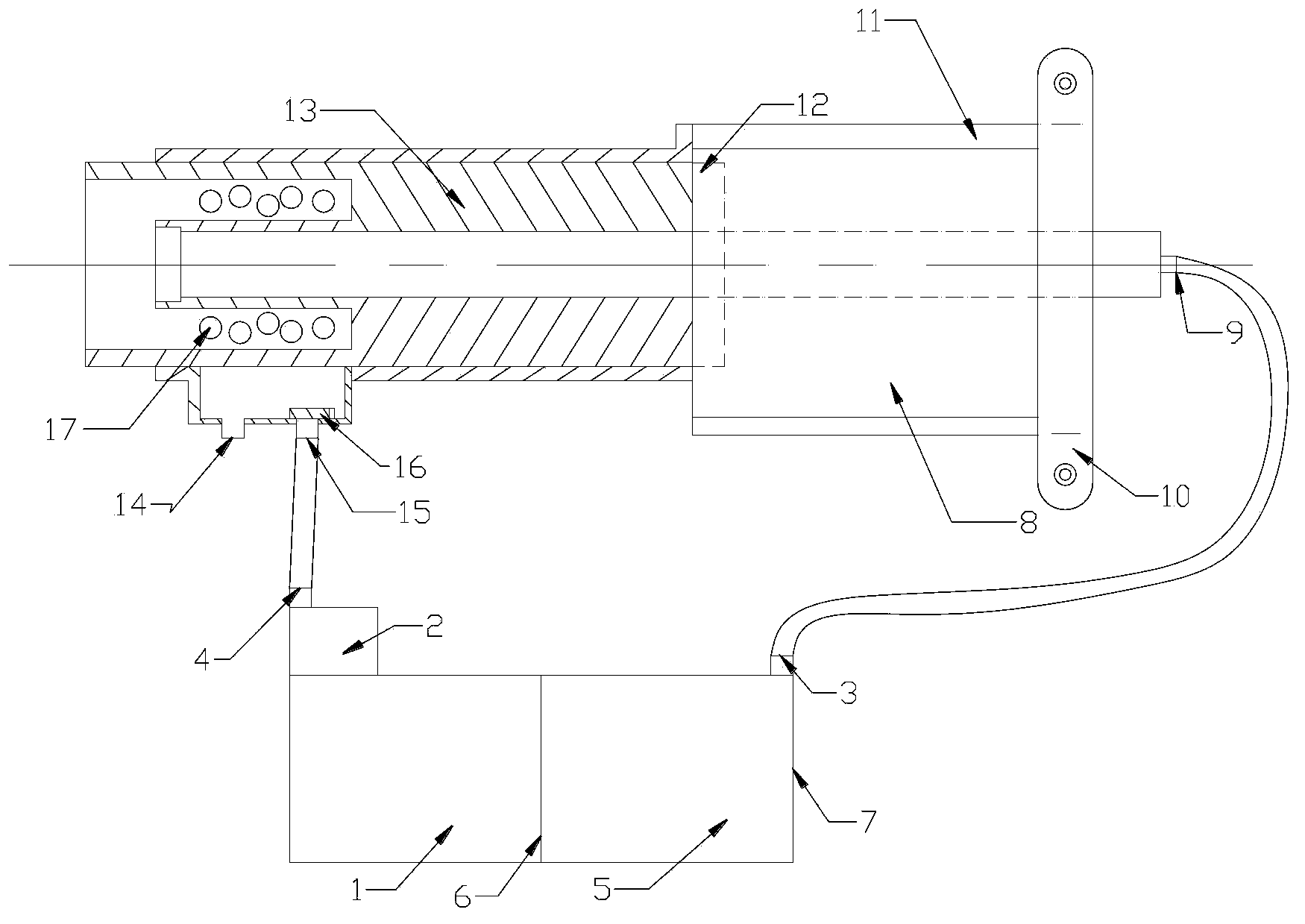

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0012] The drilling platoon separation floor anchoring drilling rig of the present invention is mainly composed of a pumping pump 2, a separation water-rock circulator 7, a motor 8, a sewage suction port 9, a bracket connector 10, a muffler 11, and a speed controller 12. The end of the motor 8 is provided with a bracket connector 10 , the bottom of the motor 8 is provided with a suction port 9 , the front end of the motor 8 is provided with a speed controller 12 , and the periphery of the motor 8 is provided with a muffler 11 . The front end of the speed governor 12 is provided with a hollow transmission shaft 13, the front portion of the hollow transmission shaft 13 is provided with an annular groove, and a plurality of water inlet holes 17 are arranged in the annular groove, and the bottom of the hollow transmission shaft 13 is provided with a water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com