Production method of high-performance environment-friendly rubber oil

An environmentally friendly rubber oil, production method technology, applied in the petroleum industry, refined hydrocarbon oil and other directions, can solve the problems of large investment, high product production cost, low product yield, etc., and achieve the effect of high yield and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

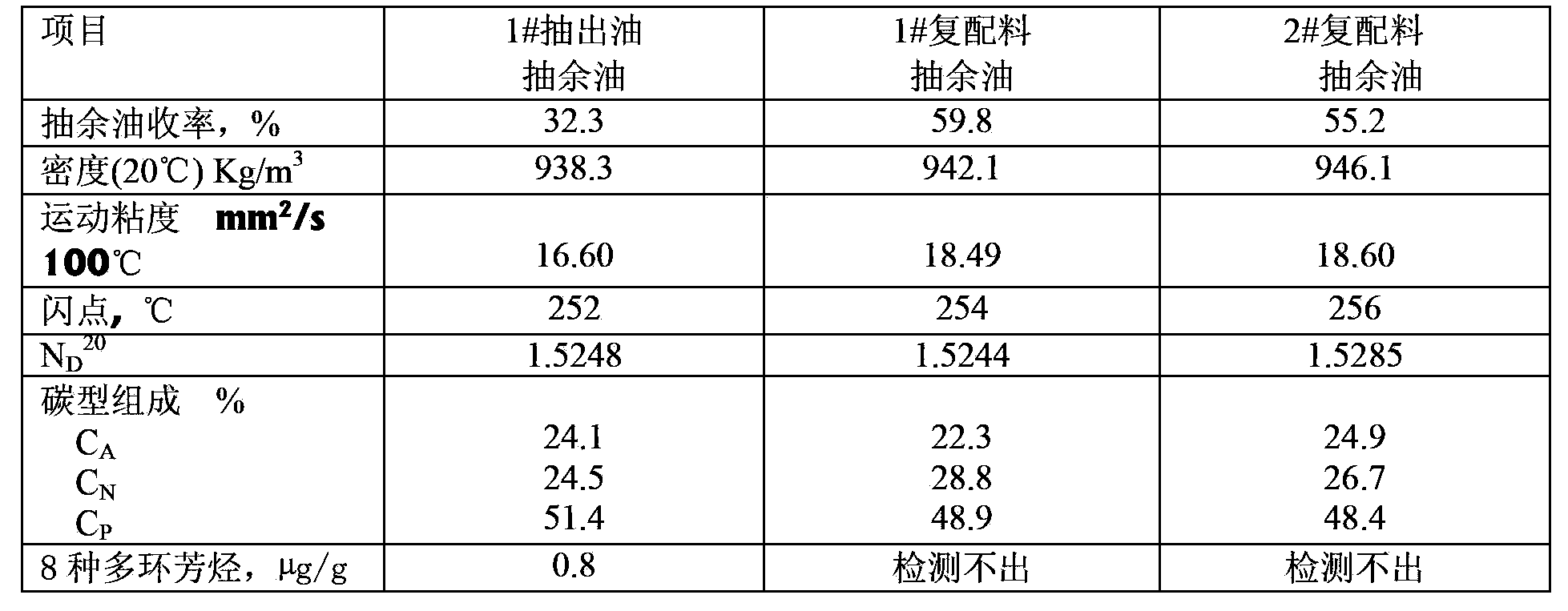

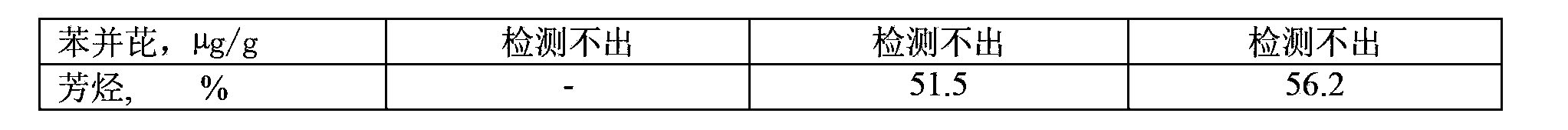

[0014] Compound 1 lubricating oil furfural refined extraction oil with a lubricating oil distillate to obtain 1# compounding and 2# compounding 2, which are used as raw materials, and furfural is used as a refining solvent in the laboratory pilot extraction device After multi-stage reverse contact refining, the yields were 59.8%, 55.2%, and the CA values were 22.3%, 24.9%, respectively. Eight kinds of polycyclic aromatic hydrocarbons met the requirements of EU environmental protection regulations 2005 / 69 / EC. High-aromatic environment-friendly rubber oil, The yield is 20-27 percentage points higher than that of the environmentally friendly rubber oil obtained by refining the 1# extracted oil alone.

Embodiment 2

[0016] 2# lubricating oil furfural refined extraction oil is compounded with a lubricating oil distillate to obtain 1# compound compound and 2# compound compound, which are used as raw materials, and furfural is used as a refined solvent in the laboratory pilot extraction device Through multi-stage reverse contact refining, yields of 57.2% and 46.6%, CA values of 15.2% and 19.9% respectively, and 8 kinds of polycyclic aromatic hydrocarbons that meet the requirements of EU environmental regulations 2005 / 69 / EC are obtained. , and the yield is 33-43 percentage points higher than that of the environmentally friendly rubber oil obtained by refining the extracted oil from 2 lubricating oil furfural.

[0017] Examples 1 and 2 use raw materials, compound ingredients and pilot test raffinate properties are shown in Table 1-Table 7 respectively.

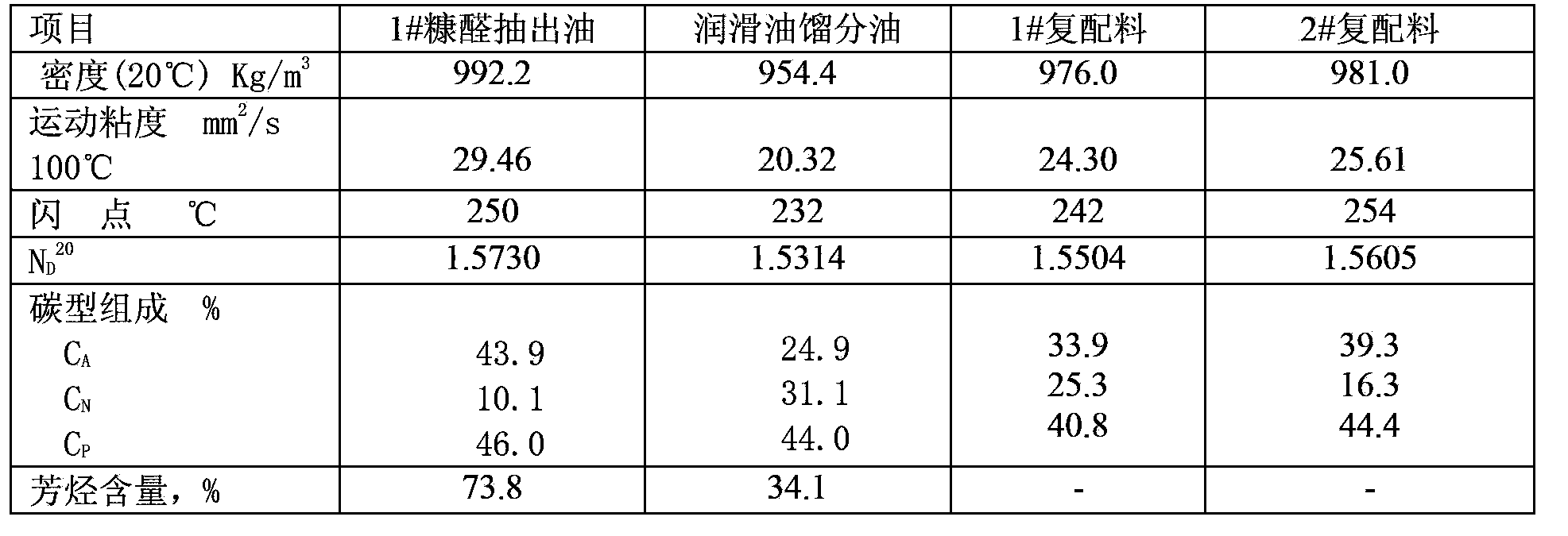

[0018] Table 1 1 Analytical data of furfural oil extracted from lubricating oil and its lubricating oil fraction compound

[0019]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com