Connector

一种连接器、腔室的技术,应用在连接器领域,能够解决易于破损、撞杆破损等问题,达到避免损伤、实现小型化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

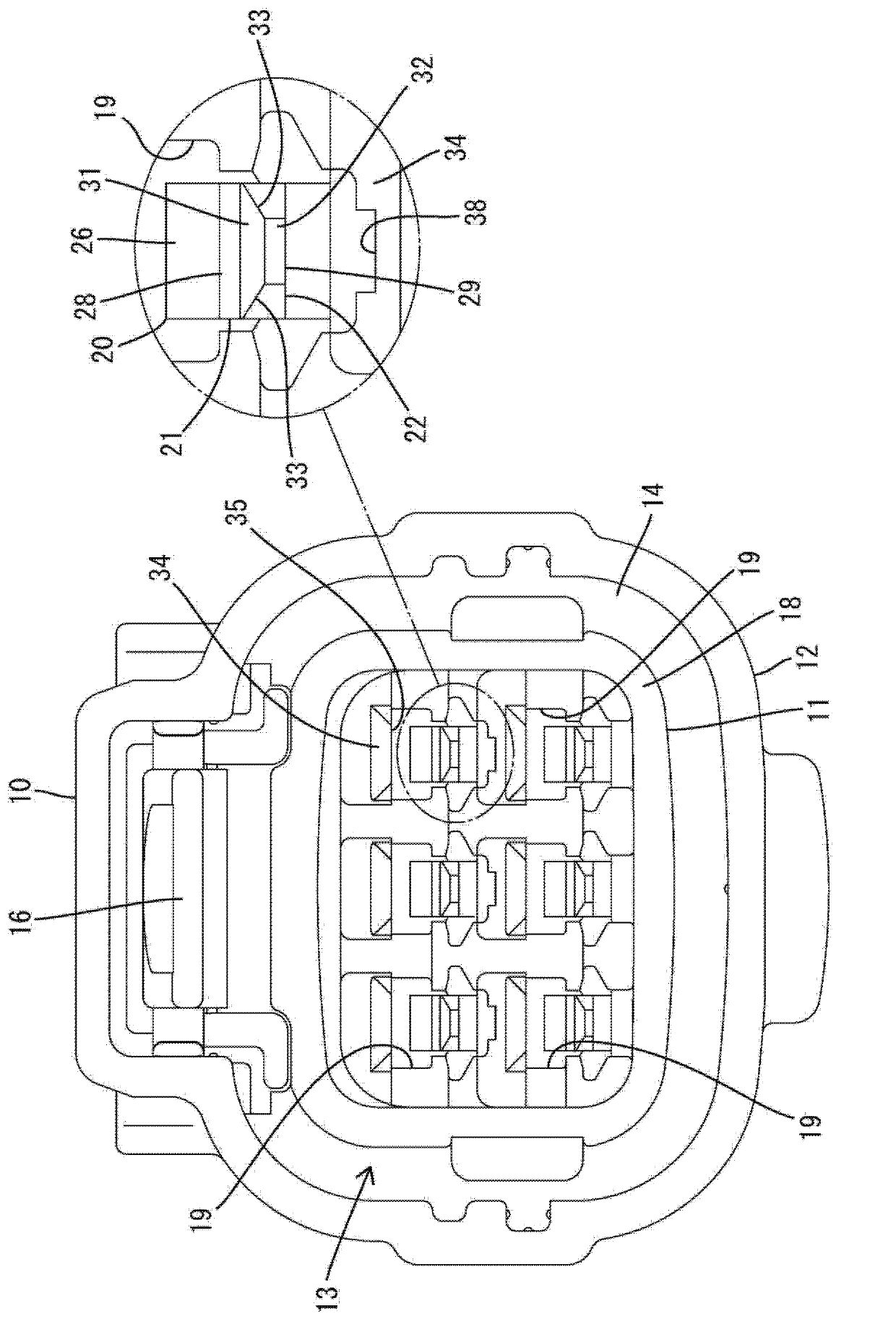

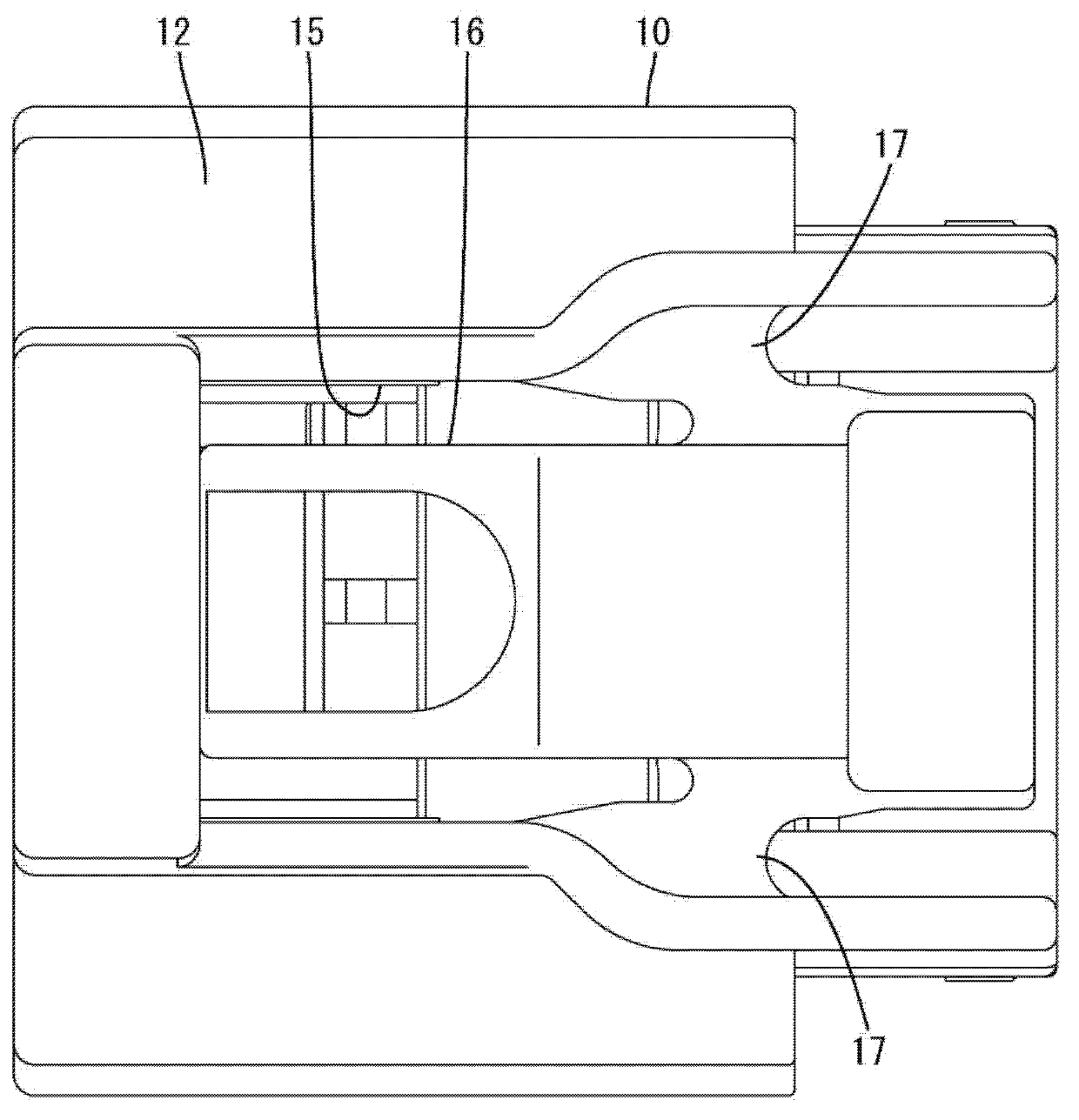

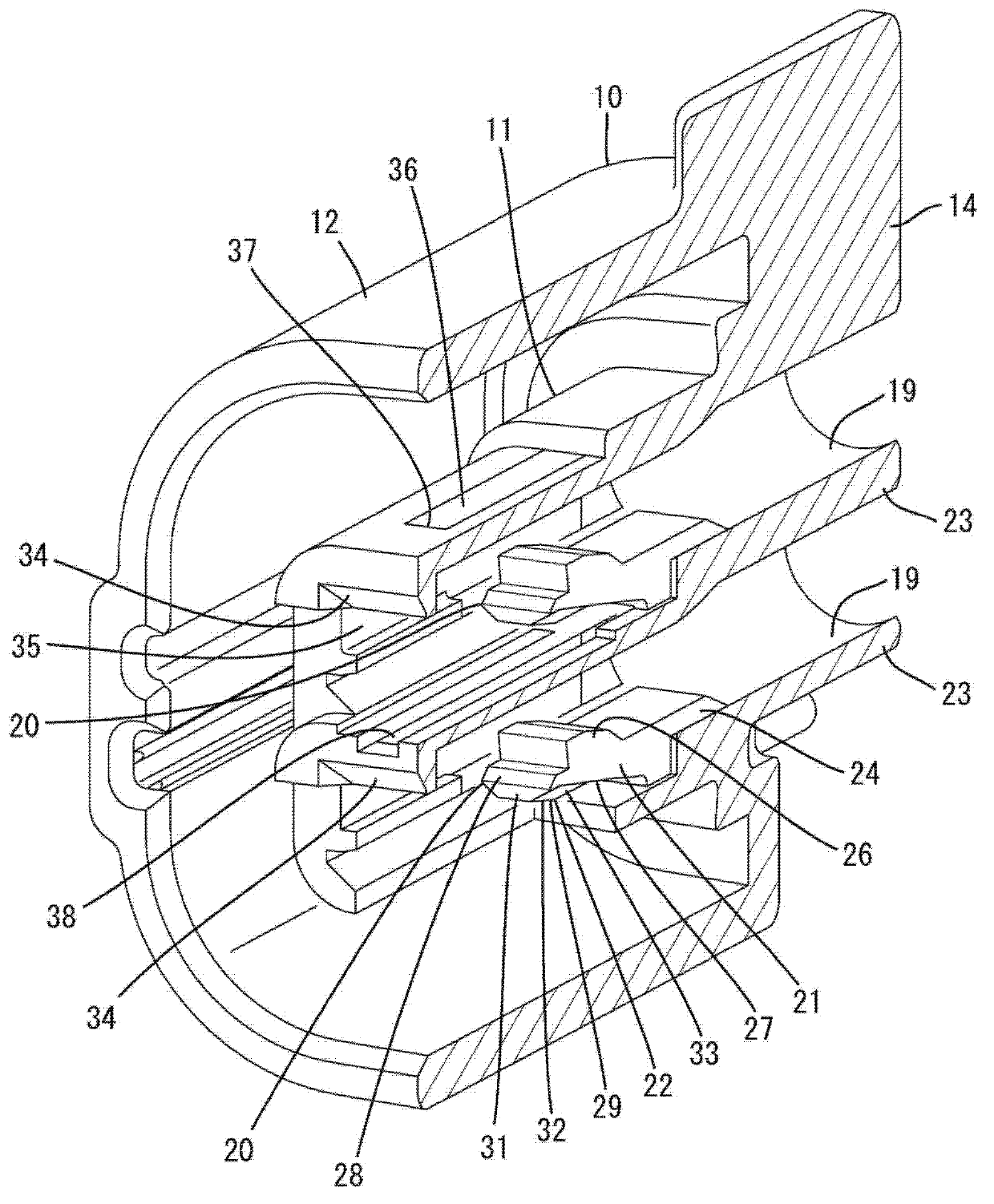

[0035] The present invention can be embodied as follows.

[0036] On the inner surface of the chamber at a position opposite to the second inclined surface, a concave portion is formed into which the inclined portion enters when the lance main body flexes and deforms. Thereby, a large amount of deflection of the lance main body can be ensured, and at the same time, the casing portion can be sufficiently reduced in size.

[0037] A through hole penetrating along the deflection direction of the lance main body is formed at a position of the housing part facing the lance main body, and a terminal that prevents the second time by restricting the bending movement of the lance main body is attached to the housing part from the front. The retainer from which the accessories come off has a locking protrusion that fits elastically into the through hole and locks with the front end of the through hole, thereby preventing the retainer from falling off from the housing. For example, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com