Construction method for longitudinally connecting and laying ballastless track slabs

A construction method and ballastless track technology, applied in tracks, roads, ballast layers, etc., can solve the problems of delay in construction period, low efficiency, and the performance of CA mortar layer is difficult to meet the durability requirements of ballastless track high-speed railways. The effect of improving construction efficiency and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

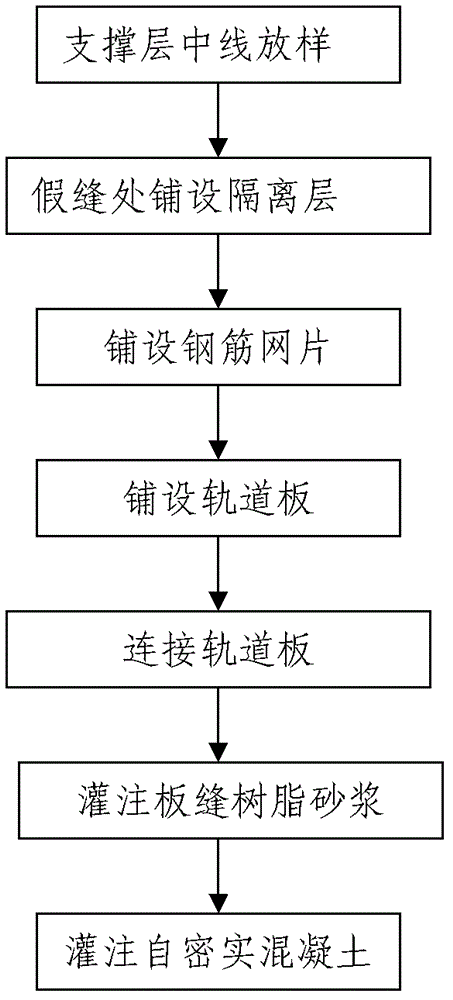

[0035] Taking the laying of two ballastless longitudinally connected track slabs as an example, the length of the track slab 1 is 4856mm, and the superheight is 49mm; the length of the track slab 2 is 5350mm, and the superheight is 50mm. The construction flow chart of the track slab is as follows figure 1 Shown:

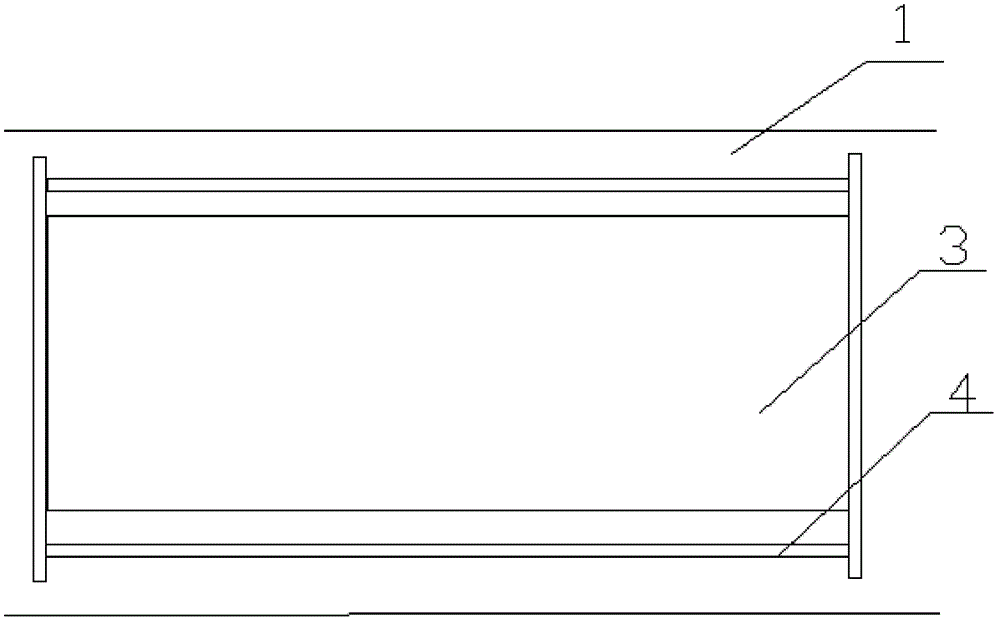

[0036] (1) Lay support layer 1: Lay a layer of hydraulic support layer on the roadbed. False seams 5 are cut on the support layer 1. After the support layer 1 is laid, the acceptance is carried out. The center line of the support layer that passes the acceptance is carry out stakeout;

[0037] Use a total station to stake out the midline positions of plates 1 and 2 on the hydraulic support layer and mark the positions with red paint, and number the staked out positions according to the design plate number.

[0038] (2) laying an isolation layer: an isolation layer 6 is laid on the false joint 5 of the support layer 1, and the isolation layer is a waterproof membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com