Active dry saccharomyces rouxii and production method thereof and prepared sauce product and method thereof

A technology of active dry yeast and Luxie yeast, which is applied in the field of Luxie active dry yeast, can solve the problems of being unsuitable for large-scale production, cumbersome operation, and poor production stability, so as to reduce the frequency of production instability, improve the aroma of alcohol esters, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

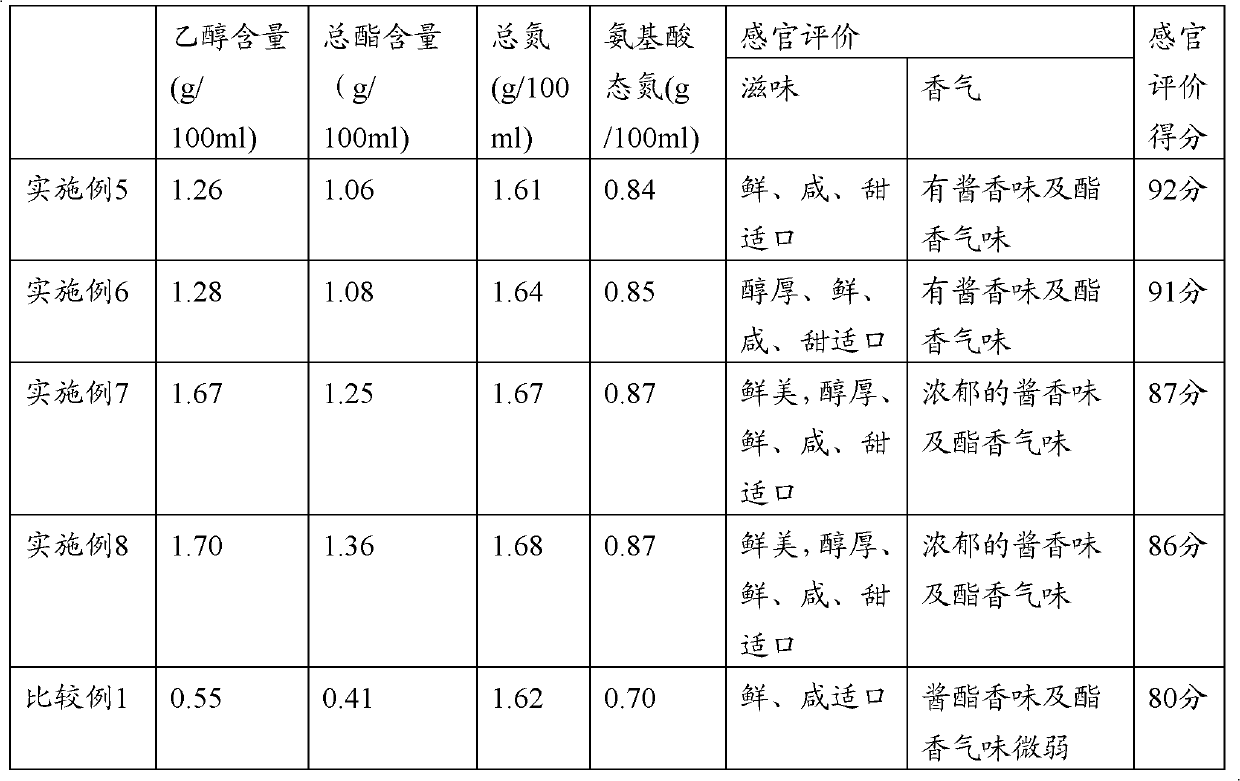

Examples

Embodiment 1

[0108] 1) Slant strain culture: Inoculate the Lu's yeast strain on a wort agar solid slant with a sugar content of 5% by weight and a pH value of 4, and cultivate at 24°C for 24 hours to obtain a slant yeast strain;

[0109] 2) First-level liquid seed F bottle culture: Inoculate 1 loop of the slant yeast strain from step 1) into 100ml bottle F with a sugar content of 5% by weight and a pH value of 4, and cultivate at 24°C In 24 hours, about 100ml of first-level liquid seed culture solution is obtained;

[0110] 3) Cultivation of the second-level liquid seed in a Cartesian tank: inoculate the first-level liquid seed culture solution of step 2) into a Carterian tank with a pH of 4 containing 10L of wort with a sugar content of 5% by weight. Cultivate for 15 hours at 24°C to obtain about 10L of secondary liquid seed culture solution;

[0111] 4) Fermentation tank seed culture: inoculate the secondary liquid seed culture solution to 1m 3 The starch hydrolyzed sugar with a sugar content ...

Embodiment 2

[0119] 1) Slant strain culture: inoculate the Lu's yeast strain on a wort agar solid slant with a sugar content of 20% by weight and a pH of 5, and cultivate at 35°C for 48 hours to obtain a slant yeast strain;

[0120] 2) First-level liquid seed F bottle culture: inoculate 6 loops of the slant yeast strain from step 1) into 250 wort F bottle with a sugar content of 20% by weight and a pH of 5, and cultivate at 35°C After 48 hours, about 250ml of first-level liquid seed culture solution was obtained;

[0121] 3) Cultivation of the second-level liquid seed in a Cartesian tank: inoculate the first-level liquid seed culture solution of step 2) into a Carterian tank containing 20L of sugar cane molasses with a sugar content of 20% by weight and a pH of 5, Cultivate at 35°C for 48 hours to obtain a secondary liquid seed culture solution;

[0122] 4) Fermentation tank seed culture: inoculate the secondary liquid seed culture solution to 3m 3 Sugar cane molasses with a sugar content of 20%...

Embodiment 3

[0129] 1) Slant strain culture: inoculate the Lu's yeast strain on a wort agar solid slant with a sugar content of 10% by weight and a pH value of 6, and cultivate at 30°C for 36 hours to obtain a slant yeast strain;

[0130] 2) First-level liquid seed F bottle culture: Inoculate 4 loops of the slant yeast strain from step 1) into 500ml bottle F with a sugar content of 10% by weight and a pH of 6 and cultivate at 30°C Within 36 hours, about 500ml of first-level liquid seed culture solution was obtained;

[0131] 3) Secondary liquid seed Cartridge culture: Inoculate the primary liquid seed culture solution of step 2) into 40L of a mixture of wort and beet molasses with a sugar content of 10% by weight, and a pH of 6 Cultivate for 30 hours at 30°C in a pottery tank to obtain a secondary liquid seed culture solution;

[0132] 4) Fermentation tank seed culture: inoculate the secondary liquid seed culture solution to 5m 3 A mixture of starch hydrolyzed sugar and beet molasses (1:1) with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com