Extruding mould applicable to PET (Polyethylene Terephthalate) profiled bar

A technology for extrusion dies and profiles, which is applied in the field of extrusion dies for extrusion of PET profiles, can solve problems such as reduced mechanical properties, low melt strength, and insufficient back pressure, and achieve increased melt pressure and high mechanical properties. , the effect of slowing down the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

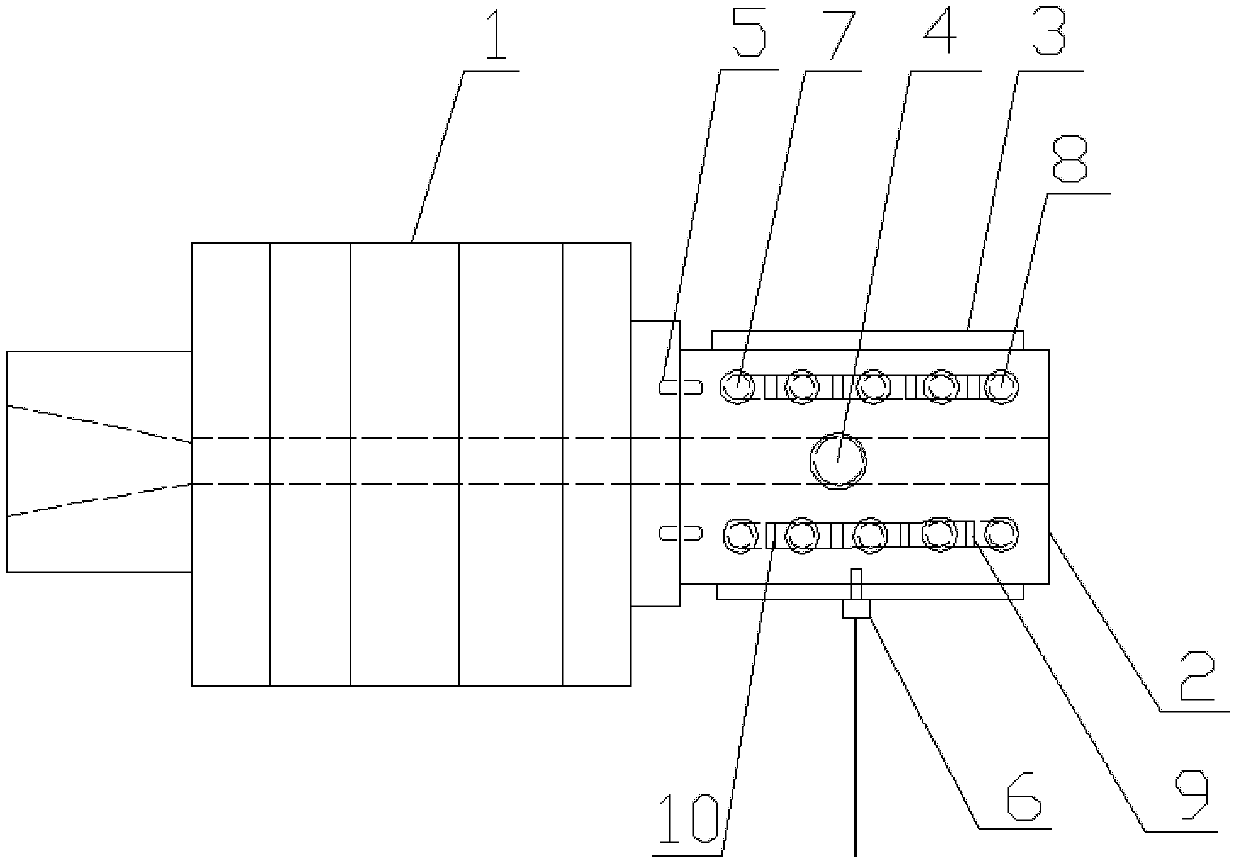

[0024] Such as Figure 1-2 As shown, the extrusion die of the present invention includes a die head 1, a calibrating die 2, a vacuum suction port 4, a calibrating die water channel 9, a water inlet 7, a water outlet 8, a blocking block 10 and an air groove 11, and also includes a heating plate 3, a positioning Pin 5 and molded thermal sensor 6.

[0025] The die head 1 and the calibrating die 2 are connected by positioning pins 5, thereby ensuring accurate center positioning of the die head 1 and the calibrating die 2, and reducing product defects caused by misalignment. The positioning pin 5 is arranged at the left end of the die head, Used to connect stereotypes. The calibrating mold 2 is provided with a heating plate 3, a calibrating mold thermal sensor 6, a water inlet 7, a water outlet 8, and a vacuum suction port 4, and the calibrating mold 2 opens a setting mold water channel 9 and an air groove 11. There are 2 heating plates 3, which are respectively arranged on the t...

Embodiment 2

[0030] Same as embodiment 1, wherein the upper and lower water inlets are respectively 2. There are 3 water outlets up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com