Processing method and concentricity measuring tool for coaxial hole of diesel engine oil supply unit casing

A technology of an oil supply unit and a processing method, which is applied in the direction of manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of complicated operation, high cost, and high price, and achieve simple operation, low manufacturing cost, and easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

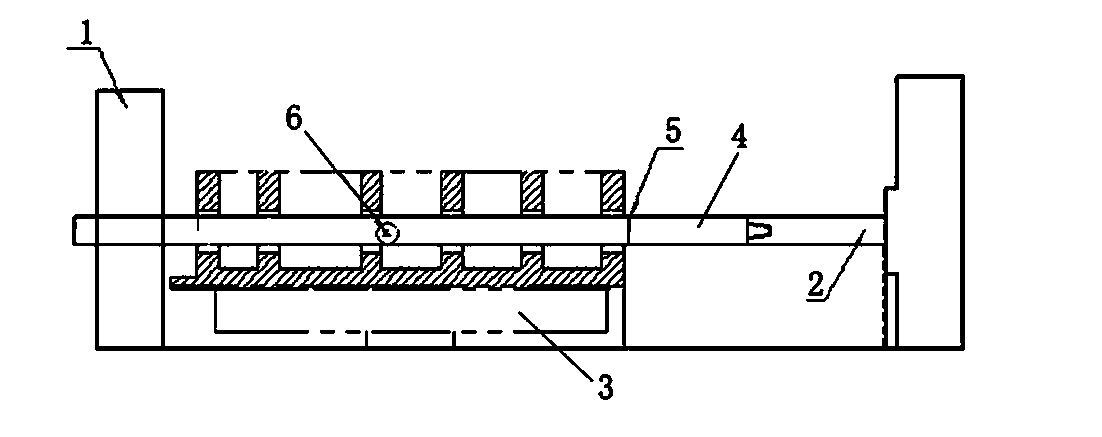

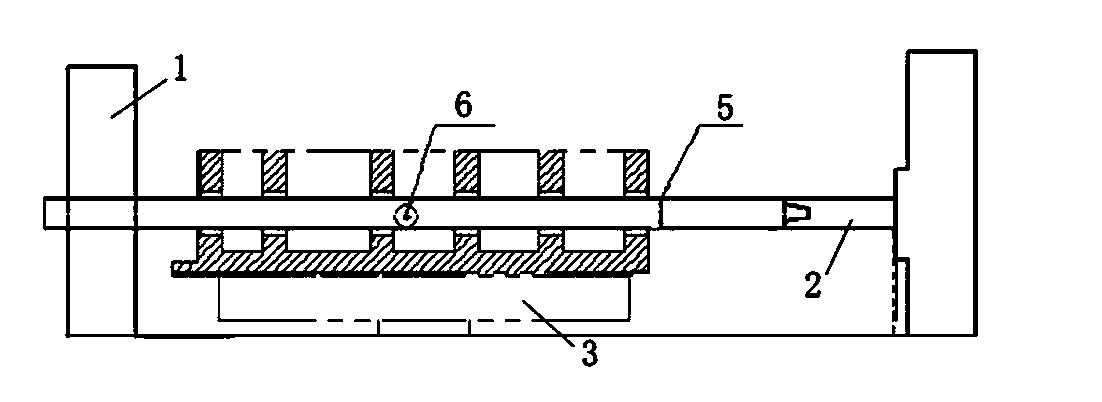

[0032] Step 1: First, adjust the distance between the tailstock and the main shaft to 3400mm;

[0033] Step 2: Place the workpiece in the middle of the workbench and install and press it tightly. The longitudinal stroke is 1600mm;

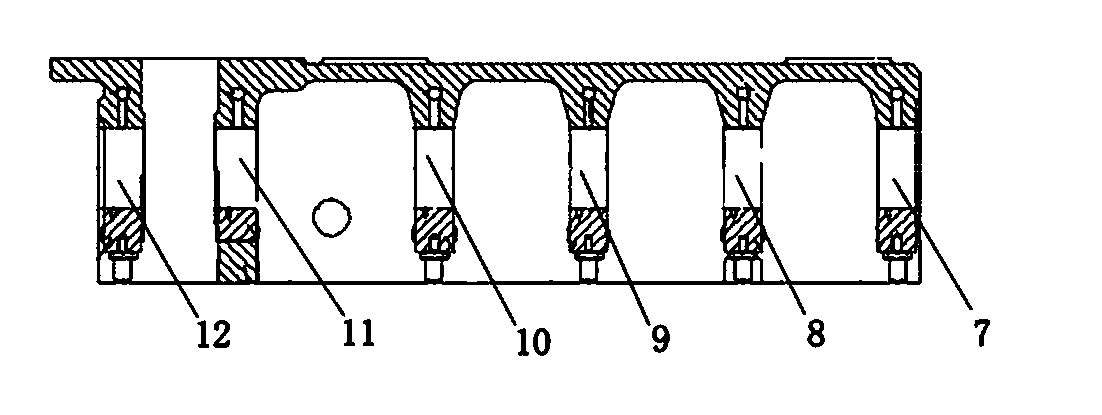

[0034] Step 3: Fix one end of the boring bar to the main shaft, install the other end of the boring bar in the tailstock bearing bush, and then adjust the center height of the boring bar. There are first and second slots for installing boring tools on the boring bar. The tool is loaded into the first tool slot of the boring row against the main shaft of the machine tool;

[0035] Step 4: The workbench moves longitudinally, the boring tool in the first slit is rough-bored close to the first three holes of the machine tool spindle to Φ194±0.2, and the center distance is controlled. Then, the workbench is reset, and the machine tool spindle and workpiece do not move;

[0036] Step 5: Put the lever dial indicator into the second slot of the boring row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com