Powder cosmetic material brush

A technology for cosmetics and powders, applied in the field of brushes for powder cosmetics, which can solve problems such as poor retention and poor collection of powder cosmetics, and achieve an effect that is easy to adapt to the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] Next, a production example of the brush for powder cosmetics of the present invention and an example of characteristic evaluation of a brush for powder cosmetics using the brush for powder cosmetics will be described in detail.

manufacture example

[0104] Polytrimethylene terephthalate (PTT) monofilaments with a twisting pitch of 16 mm and a diameter of 80 μm are used as the wool material, and the number of S-twisted and Z-twisted wool monofilaments is 7000, respectively. They were mixed adjacent to each other and cut to form bundles (diameter 4.5 cm, length 8 cm).

[0105] The end of one side of the bundled body was immersed in a treatment solution of 100 g / liter of sodium hydroxide and 6 g / liter of quaternary amine (DYK-1125: manufactured by Yibangsha Oil Industry Co., Ltd.), and treated at 130° C. for 130 minutes. Perform fine processing.

[0106] This bundle was put into a can for forming brush bristles, and a bristle portion with a swelled central portion was formed according to the inner shape of the can while applying vibration.

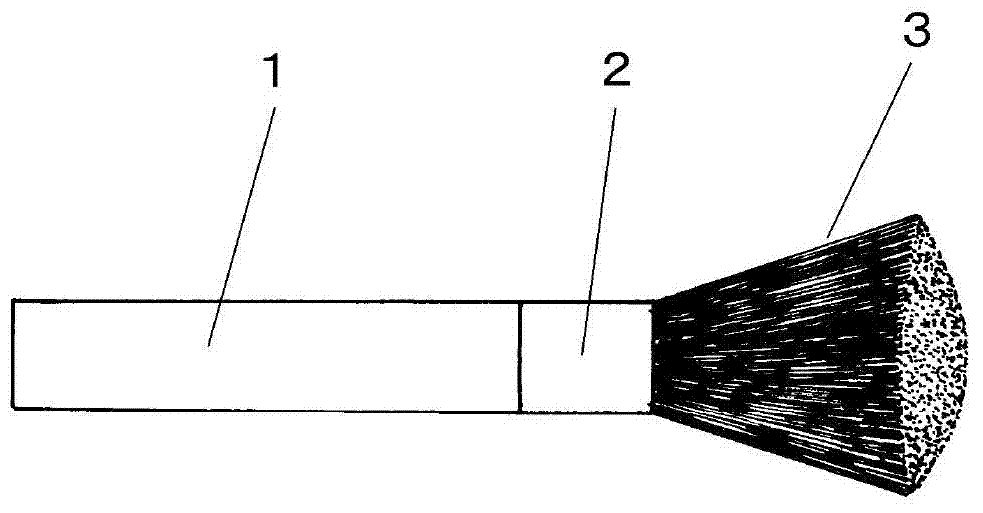

[0107] The formed bristle part is inserted into a cylindrical joint provided at the top end of the handle part of the brush, and the joint is crimped to form a brush. The outside diame...

Embodiment 1

[0116] Using the brush for powder cosmetics produced in the above-mentioned production example, the collection property (adhesion property) and the powder release property (powder-containing property) were evaluated according to the above-mentioned usability evaluation method of the brush, and the results are shown in Table 1.

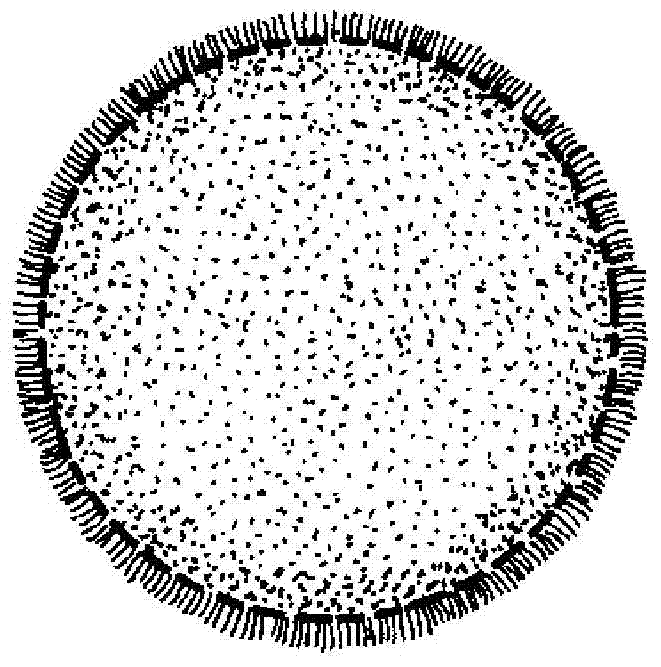

[0117] The evaluation results of trapping properties are shown in Figure 2A and Figure 2B .

[0118] As can be seen from the drawings, the collected powder cosmetics are uniformly adhered to the entire tip of the bristle material forming the bristle portion.

[0119] On the other hand, regarding the release properties of powders, if Figure 4 As shown by (mark), it can be seen that even if N2 / N1 exceeds 4, the powder is released and applied to the skin surface. From this, it can be seen that the powder-containing property of the bristle portion is good, and has a characteristic of releasing the powder gradually at the time of application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com