Heat radiating circuit and electronic device comprising heat radiating circuit

A technology for electronic equipment and circuits, which is applied in the field of heat dissipation circuits and electronic equipment with heat dissipation circuits, can solve the problems of variable speed of energy saving effect, adjust the rotation speed of fans, etc., and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

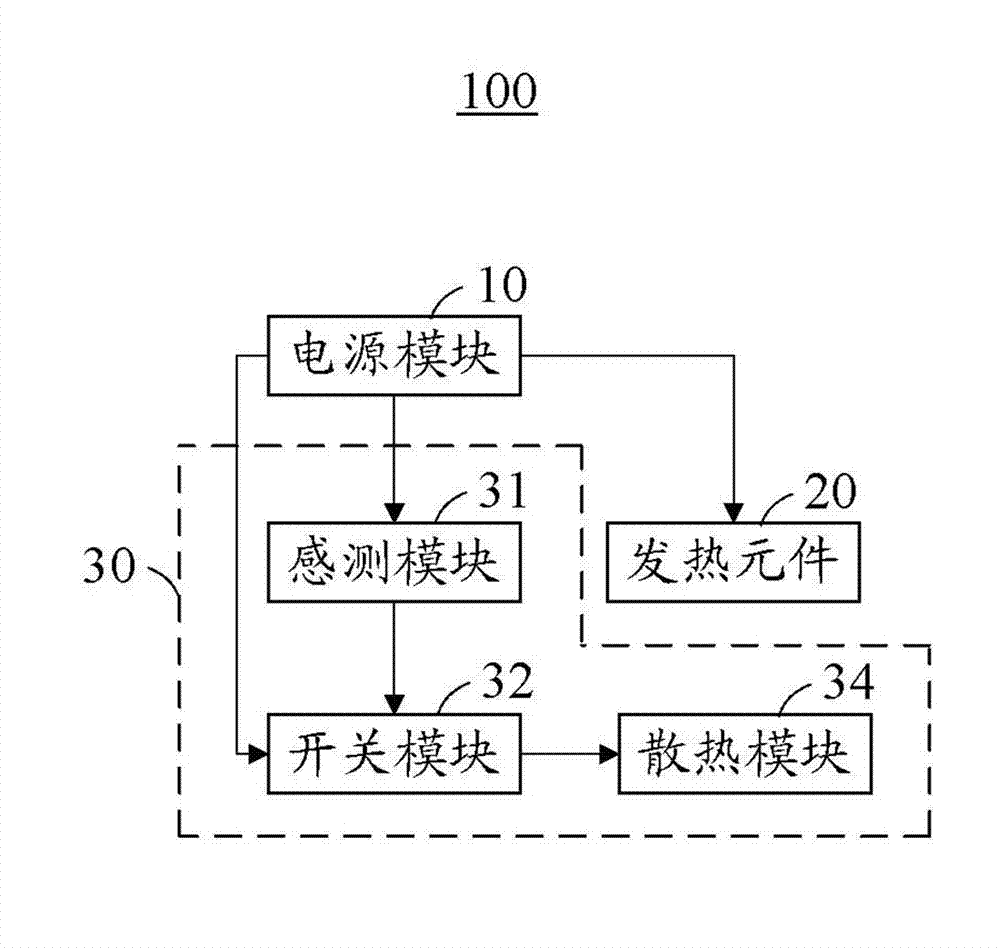

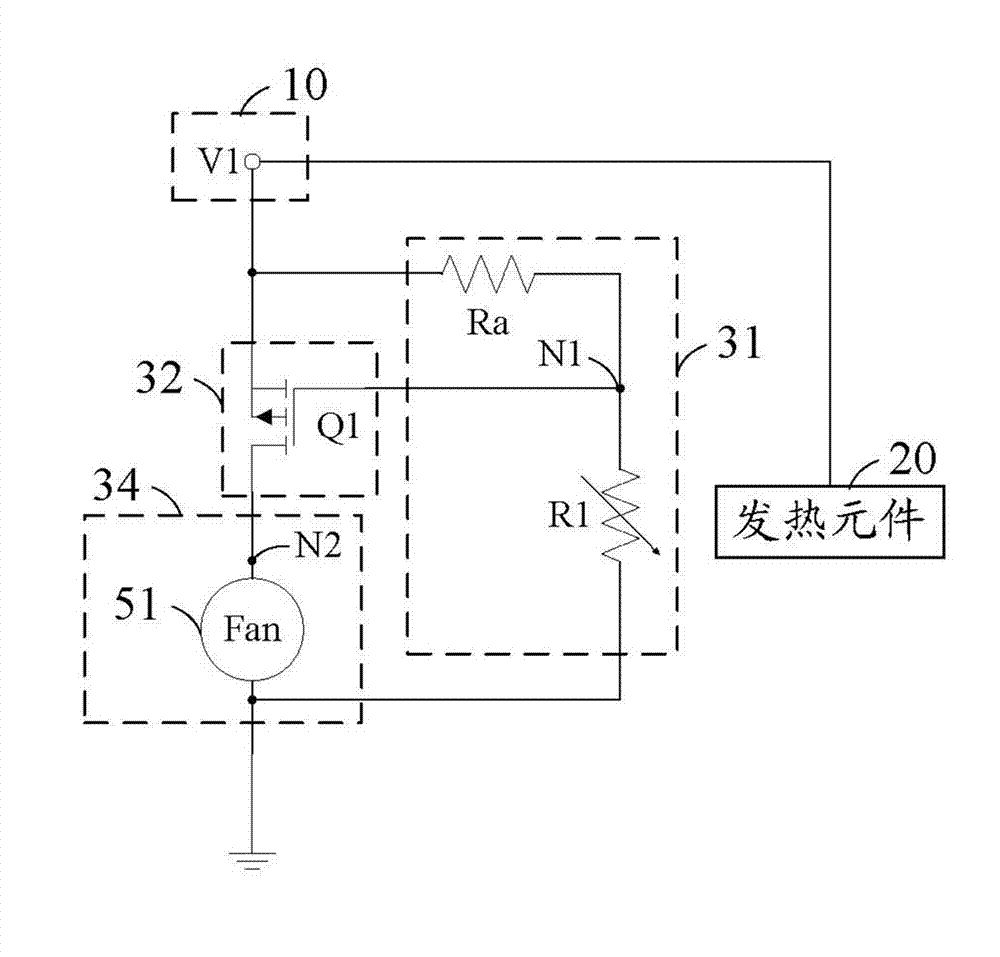

[0013] see figure 1 , which is a functional block diagram of the electronic device 100 in a preferred implementation manner. The electronic device 100 includes a power module 10 , a heating element 20 and a cooling circuit 30 . The electronic device 100 may be an electronic device with heat dissipation elements such as a computer, an air conditioner, and a television.

[0014] The power module 10 is used to supply power to the heating element 20 and the cooling circuit 30 . In this embodiment, the working voltage of the power module 10 is 5V.

[0015] The heating element 20 is used to receive the power supply voltage of the power module 10 to work and generate heat. In this embodiment, the heating element 20 is a high-power electronic element in the electronic device 100 .

[0016] The heat dissipation circuit 30 is used for dissipating heat from the heating element 20 . The cooling circuit 30 includes a sensing module 31 , a switch module 32 and a cooling module 34 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com