PWM variable frequency speed control system based on control of DSP

A technology of variable frequency speed regulation and speed measurement, which is applied to control systems, vector control systems, and control generators, etc., and can solve problems such as unstable magnetic flux, complex structure, and large amount of vector transformation calculations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

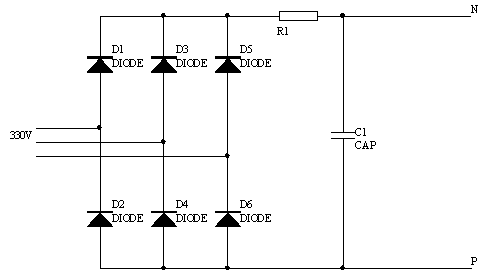

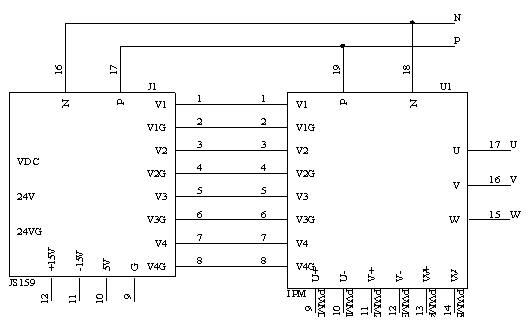

[0018] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention takes TI's DSP chip TMS320LF2407A as the core, including several parts of main circuit, detection circuit and controller. The main circuit includes a rectification filter circuit and an IPM power module; the detection circuit includes a current and voltage detection circuit and a speed measurement circuit; the rectification module in the rectification filter circuit adopts a three-phase uncontrollable rectifier bridge; inside the IPM power module, except for a three-phase full-bridge IGBT In addition, it also has built-in IGBT drive circuit, fault detection and protection circuit, and the IPM power module adopts PM25RSB120. Due to the use of IPM power modules, the structure of the main circuit is greatly simplified and the reliability is enhanced, which greatly facilitates the use of users. Start the self-protection mechanism, tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com