Manufacturing method of multi-wall carbon nanotube and polyaniline nano fiber composite supercapacitor electrode

A technology of multi-walled carbon nanotubes and supercapacitors, applied in the field of energy storage materials, can solve the problems such as the fact that the equivalent series resistance of electrodes is not significantly improved, the electrical conductivity of carbon nanotubes cannot be reflected, and it is unfavorable for industrial production. The effect of chemical expansion, high charge-discharge cycle stability, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the multi-walled carbon nanotube / polyaniline nanofiber composite supercapacitor electrode of this embodiment is carried out according to the following steps:

[0023] a. Use polystyrene sulfonic acid to disperse multi-walled carbon nanotubes: take 10 mg of multi-walled carbon nanotubes and put them into a beaker, then add 10 ml of deionized water and 300 microliters of polystyrene sulfonic acid multi-walled carbons to the beaker in turn For the nanotube solution, the multi-walled carbon nanotube solution was ultrasonicated for 40 minutes by an inserting ultrasonic instrument to obtain a uniformly dispersed multi-walled carbon nanotube solution;

[0024] b, preparation of polyaniline nanofibers: add 300 microliters of aniline monomer to 10 milliliters of chloroform to obtain the chloroform solution of aniline monomer, and dissolve 183 milligrams of ammonium thiosulfate in 10 milliliters of hydrochloric acid with a concentration of 1mol / L The hyd...

Embodiment 2

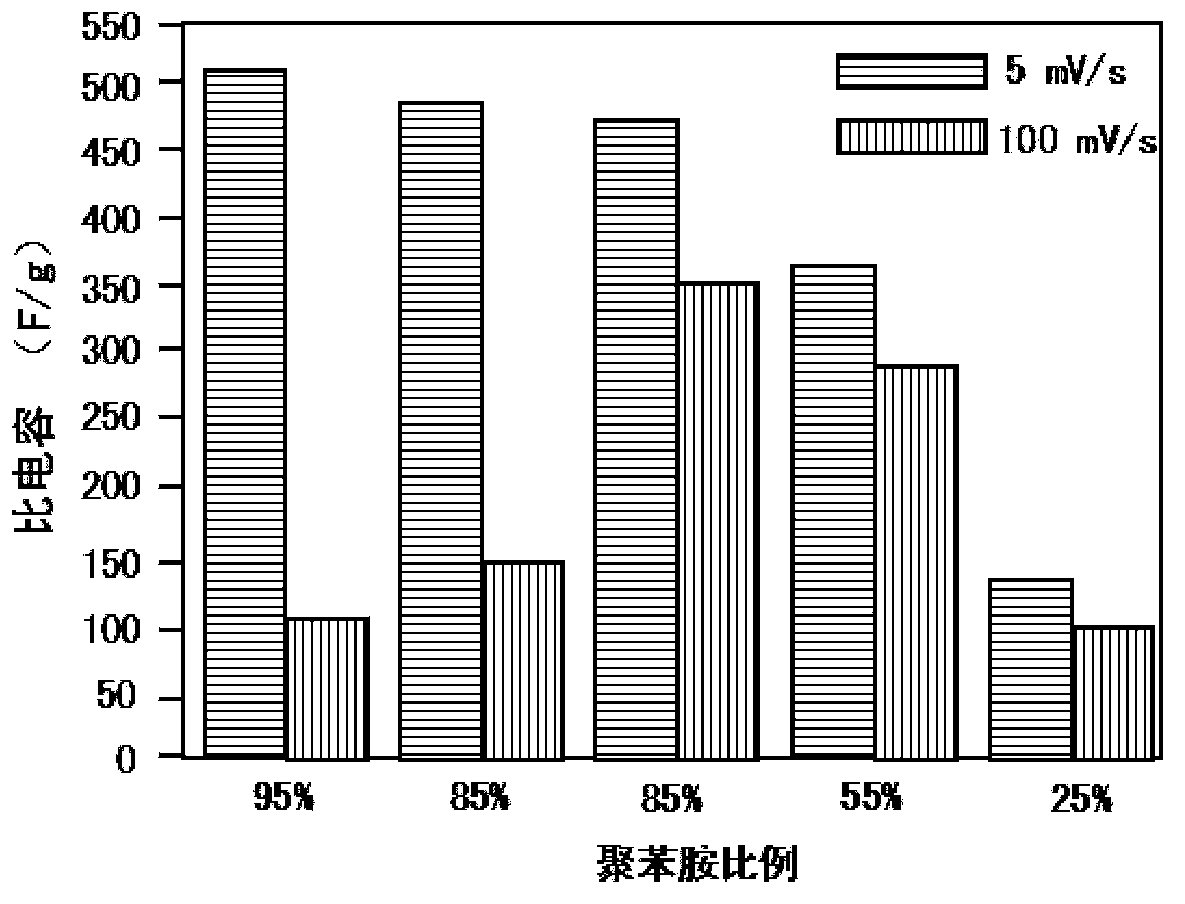

[0027] Prepare uniformly dispersed multi-walled carbon nanotube solution and polyaniline nanofibers by the same method as in Example 1, add 56.67mg of clean polyaniline nanofibers into the uniformly dispersed multi-walled carbon nanotube solution, obtain multi-walled carbon nanotubes by ultrasonic tube / polyaniline nanofiber uniform mixture, with nitrogen as carrier gas, the uniform mixture of multi-walled carbon nanotubes / polyaniline nanofibers is sprayed onto a graphite substrate with a surface area of 1cm*1cm, and then the sprayed graphite The substrate was put into a vacuum drying oven and dried under vacuum conditions at 60 degrees Celsius for 12 hours to obtain a multi-walled carbon nanotube / polyaniline nanofiber composite supercapacitor electrode with a mass ratio of polyaniline nanofibers of 85%. figure 1 It is the field emission scanning electron micrograph of the multi-walled carbon nanotube / polyaniline nanofiber composite supercapacitor electrode prepared in Example...

Embodiment 3

[0029] Prepare uniformly dispersed multi-walled carbon nanotube solution and polyaniline nanofibers in the same manner as in Example 1, add 30 mg of clean polyaniline nanofibers into the uniformly dispersed multi-walled carbon nanotube solution, and obtain multi-walled carbon nanotubes by ultrasonic / uniform mixture of polyaniline nanofibers, with nitrogen as carrier gas, the uniform mixture of multi-walled carbon nanotubes / polyaniline nanofibers is sprayed onto a graphite substrate with a surface area of 1cm*1cm, and then the graphite substrate after spraying Put it into a vacuum drying oven and dry it for 12 hours under a vacuum condition of 60 degrees Celsius to obtain a multi-walled carbon nanotube / polyaniline nanofiber composite supercapacitor electrode with a polyaniline nanofiber mass ratio of 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com