Capacitive touch screen and manufacturing method

A capacitive touch screen and electrode technology, which is applied in the direction of electrical digital data processing, instruments, calculations, etc., can solve the problems of affecting the touch sensitivity of the touch screen, insufficient charging of sensor electrodes, heavy RC load, etc., to achieve good touch effect, fast charging, Effect of reducing RC load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

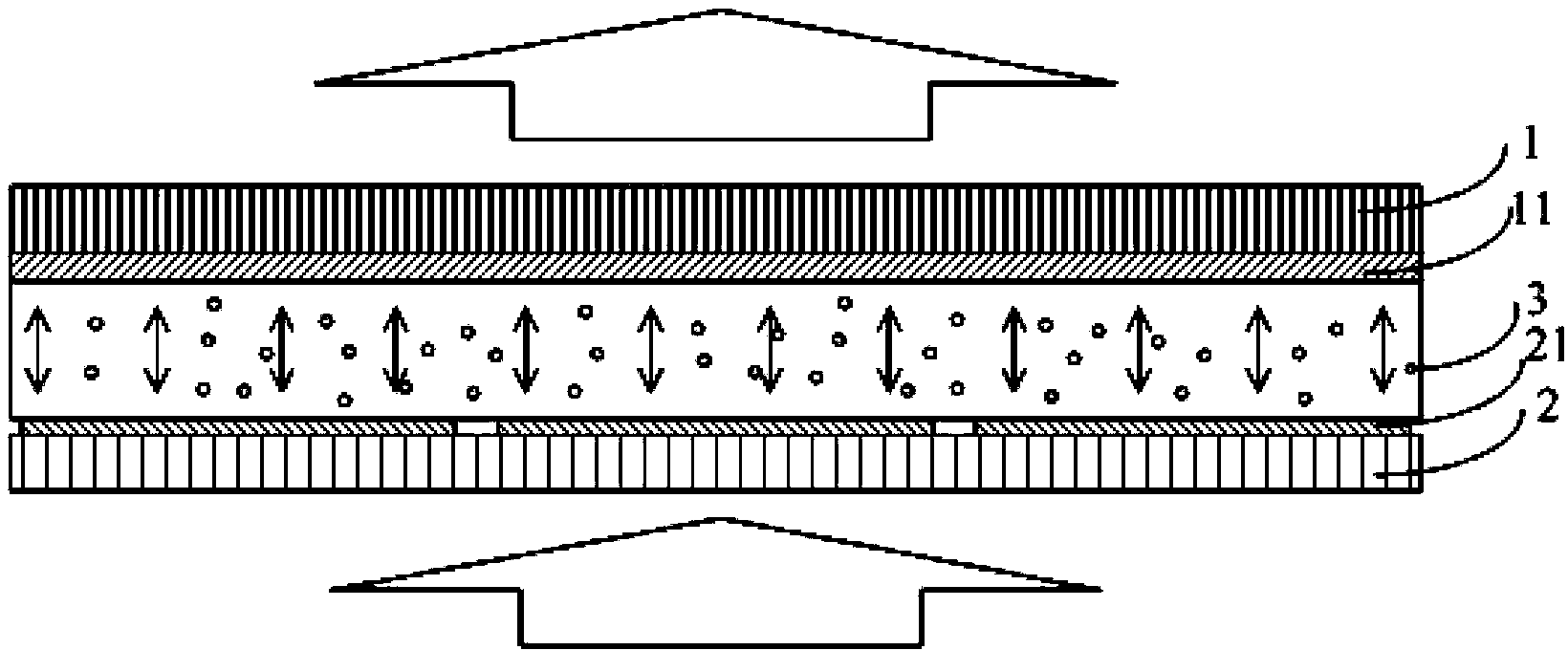

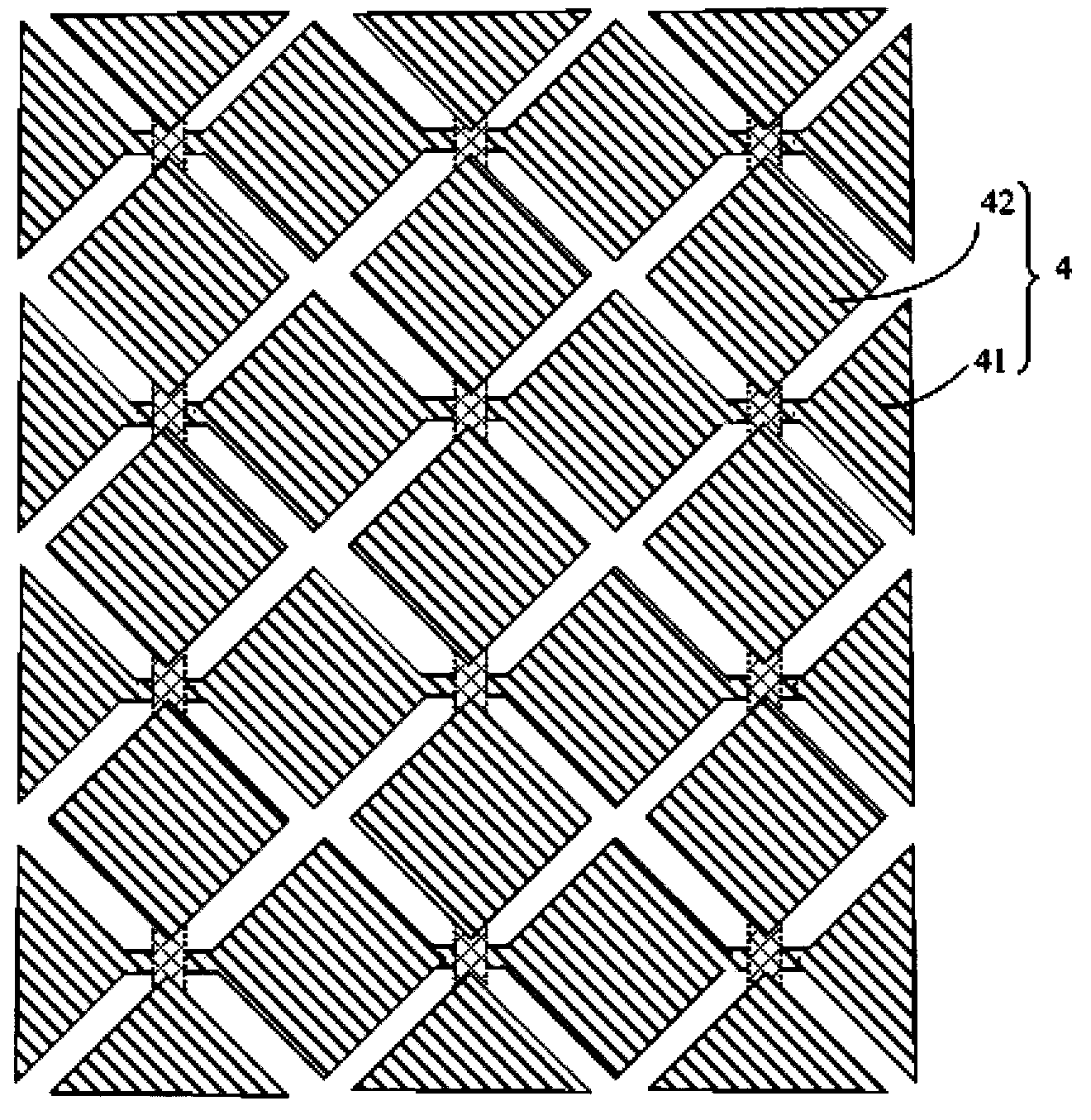

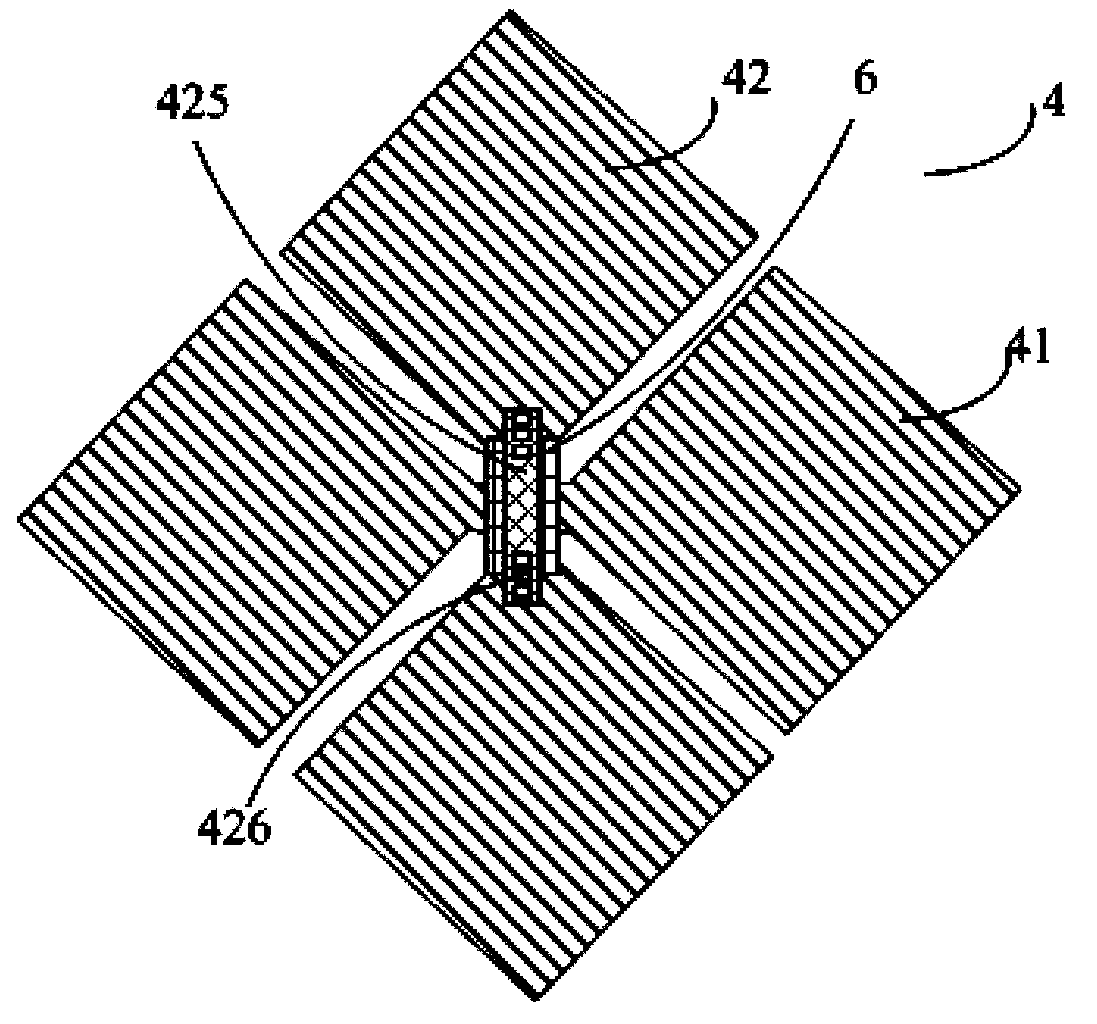

[0058] Such as Figure 5-7 As shown, the capacitive touch screen includes a substrate and a sensor electrode 4 arranged on the substrate. The sensor electrode 4 includes a first electrode group 41 arranged in parallel in multiple rows and a second electrode group 42 arranged in parallel in a plurality of columns. The first electrode group 41 includes A plurality of first electrodes 411 are electrically connected in sequence, and the second electrode group 42 includes a plurality of second electrodes 421 electrically connected in sequence. In this embodiment, both the first electrode 411 and the second electrode 421 include peripheral electrodes distributed around the periphery and a central electrode electrically isolated from the peripheral electrodes, and adjacent peripheral electrodes in the same row / column are electrically connected to each other.

[0059] Such as Figure 7 As shown, a closed first isolation trench 412 is opened in the first electrode 411. The inner side ...

Embodiment 2

[0102] The difference between this embodiment and Embodiment 1 is that, in the capacitive touch screen structure of this embodiment, the second conduction part is formed on the same layer as the first electrode and the second electrode, and the first conduction part is arranged on the second conduction part. Below the part, a via hole is provided in the insulating layer, and the first conducting part is electrically connected to the first electrode through the via hole.

[0103] In this embodiment, the first electrode, the second electrode and the second conducting part are formed by indium tin oxide; A material is formed.

[0104] Correspondingly, the preparation method specifically includes the following steps:

[0105] Step S11: forming a pattern including a first conducting portion on the substrate.

[0106] Step S12 : On the substrate after step S11 , an insulating layer is formed, and a via hole is opened in the insulating layer in a region corresponding to the end of ...

Embodiment 3

[0111] The difference between this embodiment and Embodiments 1 and 2 is that, in this embodiment, only the first electrode in the first electrode group, or only the second electrode in the second electrode group is provided with a closed isolation ditch groove.

[0112] Correspondingly, when forming the sensor electrodes in the manufacturing process, the mask used in the exposure process not only has patterns corresponding to the formation of the first electrode 411 and the second electrode 421, but also has patterns corresponding to the formation of the first isolation trench. The groove 412 (corresponding to the closed isolation trench opened in the first electrode); or, also has a pattern corresponding to the formation of the second isolation trench 422 (corresponding to the closed isolation trench opened in the second electrode). Wherein, the pattern corresponding to the formation of the first isolation trench 412 or the second isolation trench 422 is the photoresist comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com