Light guide plate production method

A manufacturing method and technology of light guide plates, applied in the direction of light guides, optics, optical components, etc., can solve problems such as slow processing speed, incapable of mass production, and difficult adjustment of UV exposure angle, so as to prevent surface chromatic aberration, easy adjustment, and exposure The effect of easy control of the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

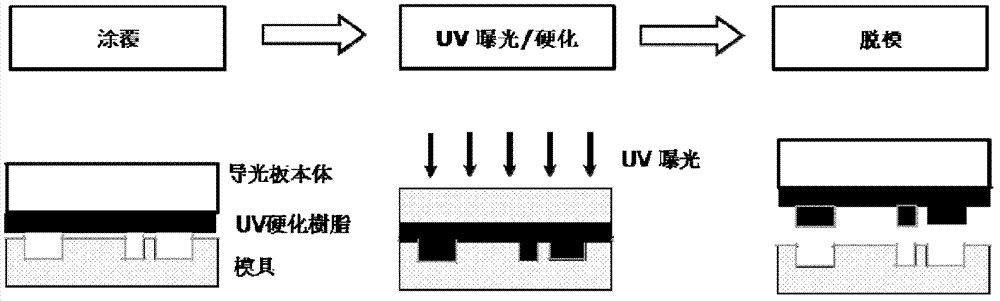

[0027] This embodiment provides a method for manufacturing a light guide plate, such as image 3 shown, including:

[0028] On the light guide plate body that is made by PMMA, coat UV hardening resin, the composition of this UV hardening resin comprises the MMA that mass percentage is 15% ( Propylene methyl ester), 20% trimethylolpropane triacrylate, 2% photoinitiator (Photoinitiator), 63% solvent;

[0029] Embossing the UV curable resin with a mold;

[0030] Release from the mold to form a scattering pattern that complements the shape of the mold;

[0031] The UV curable resin is exposed to ultraviolet light to harden the UV curable resin to form a final scattering pattern on the light guide plate body.

[0032] In the present invention, the order of exposure and demoulding is changed, and UV exposure is performed after demoulding. Compared with the prior art, the position of the exposure light source is not limited, and the angle of exposure is easier to adjust. The exp...

Embodiment 2

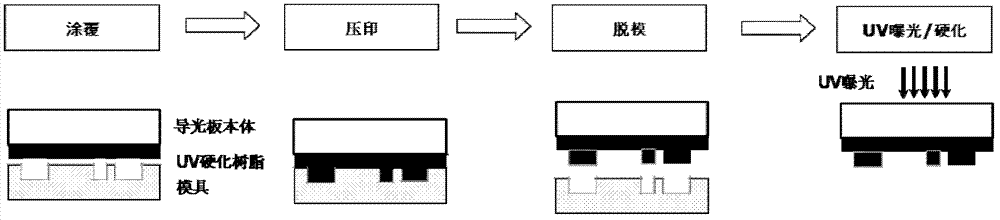

[0038] This embodiment provides a Figure 4 The manufacturing method of the shown light guide plate includes:

[0039] coating a UV curable resin on the first side of the light guide plate body;

[0040] embossing the UV curable resin on the first side of the light guide plate body with a mold having a raised pattern to form a scattering pattern;

[0041] demoulding;

[0042] exposing the UV curable resin on the first side of the light guide plate body under ultraviolet light to harden the UV curable resin, thereby forming a concave pattern complementary to the shape of the mold in the UV curable resin on the first side of the light guide plate body, As the scattering layer of the light guide plate;

[0043] coating a UV curable resin on a second side of the light guide plate body opposite to the first side;

[0044] embossing the UV curable resin on the second side of the light guide plate body with a mold having a concave pattern to form a diffusion pattern;

[0045] de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com