Intelligent spherical aggregate for concrete structure health monitoring

A concrete structure and smart aggregate technology, applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of reducing monitoring sensitivity and accuracy, and achieve high reliability of information, widening of frequency response range, high sensitivity and signal quality. The effect of the noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

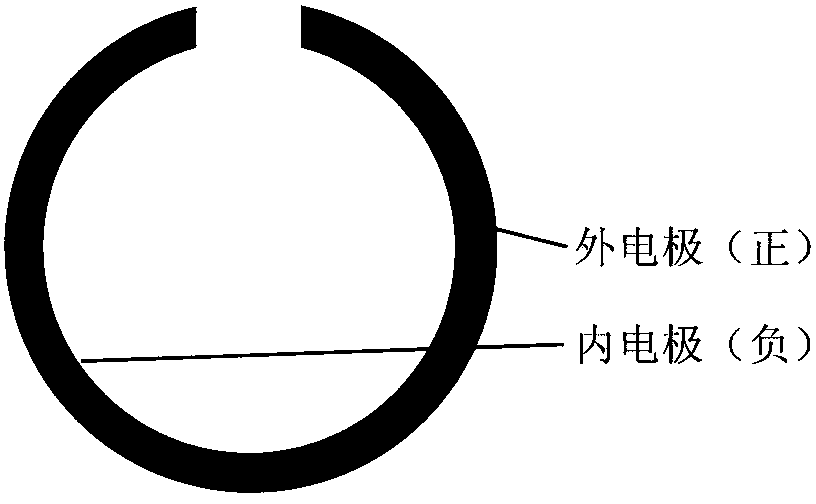

[0023] The manufacturing process of the hollow spherical cement-based piezoelectric composite sensor is as follows:

[0024] First, hollow spherical cement-based piezoelectric composites are molded, as shown in the attached figure 1 shown. The cement-based piezoelectric composite material is composed of PZT piezoelectric ceramic particles with a particle size distribution in the range of 40-110 microns and ordinary Portland cement powder with a particle size distribution in the range of 4-40 microns as raw materials. Adopting such a particle size distribution can ensure the compactness of the cement-based piezoelectric composite material and achieve the effect of maximum accumulation, so as to improve the piezoelectric performance of the composite material.

[0025] Then, the PZT piezoelectric ceramic particles and cement powder should be ball milled and mixed acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com