A method for testing the rotating speed lifting transient performance of an engine under a fixed torque condition

A technology of transient performance and testing method, which is applied in the direction of internal combustion engine testing, etc. It can solve the problems that the engine output characteristics cannot reflect the engine transient output characteristics, the engine development cycle is long, and the repeatability of the vehicle test conditions is difficult to maintain consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

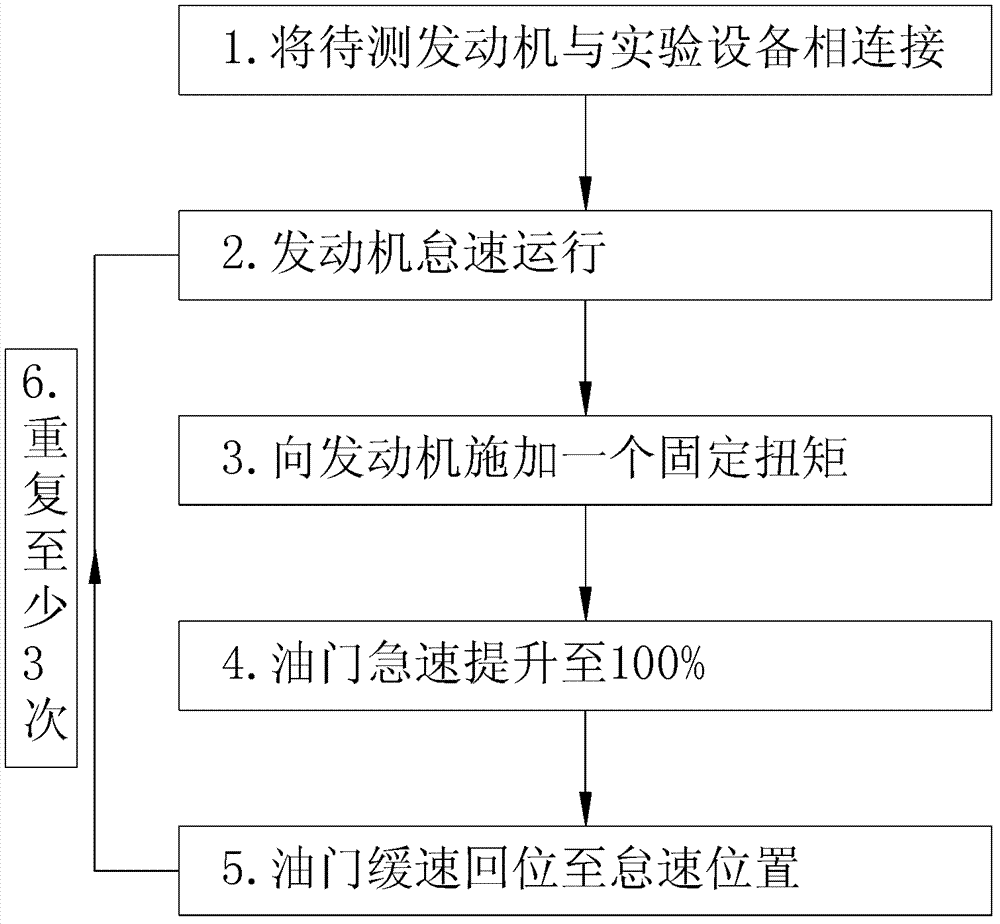

[0025] A test method for engine transient performance constant torque speed increase, such as figure 1 shown, including the following steps:

[0026] ① Connect the engine to be tested with the dynamometer;

[0027] ② The engine is running at idle speed;

[0028] ③ Apply a fixed torque that is less than the maximum load capacity at idle speed to the engine (i.e. apply a fixed torque that is less than the maximum load capacity of the engine at idle speed), and keep the engine running stably for at least 5 minutes under this fixed torque, while testing the engine Output characteristics after the loading torque stabilizes;

[0029] ④Raise the throttle of the engine from the idle position to 100% and hold it fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com