Self-heating full-contact type air dehumidifying device

An air dehumidification, full-contact technology, applied in heating methods, lighting and heating equipment, and shielding with air flow, etc., can solve the problems of air heat exchange, large heat exchange area, and high manufacturing cost that are not suitable for large flow. The effect of saving installation cost, reducing equipment weight, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

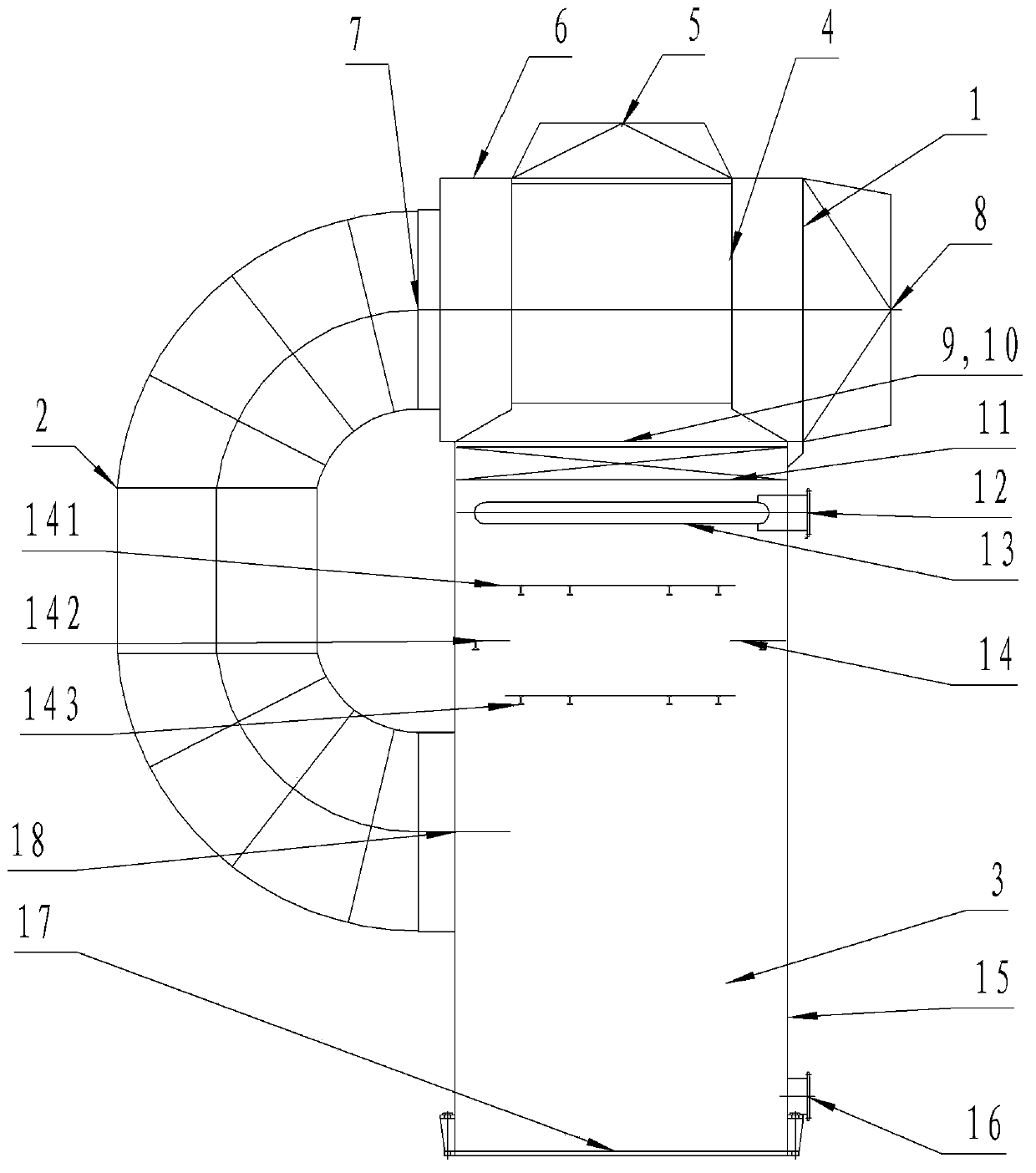

[0021] Embodiment 1, a self-heating full-contact air dehumidification device, including a dehumidification device with a high-temperature humid air inlet 8 and a dehumidified cold air outlet 5, characterized in that the dehumidification device is composed of a plate heat exchanger 1, an air flow channel 2. The cooling and dehumidification tower is composed of 3; the cooling and dehumidification tower is vertically arranged, the plate heat exchanger shell 6 is fixed above the cooling and dehumidification tower, the air outlet 10 of the dehumidification tower is connected with the cold air inlet 9 of the plate heat exchanger, and the plate heat exchanger The high temperature and humid air outlet 7 of the shell is connected to one end of the C-shaped air passage, and the other end of the air passage is connected to the dehumidification tower air inlet 18 located at the lower part of the cooling dehumidification tower.

[0022] The plate heat exchanger is composed of high-temperatu...

Embodiment 2

[0024] Embodiment 2, a self-heating full-contact air dehumidification device, including a dehumidification device with a high-temperature humid air inlet 8 and a dehumidified cold air outlet 5, characterized in that the dehumidification device is composed of a plate heat exchanger 1, an air flow channel 2. The cooling and dehumidification tower is composed of 3; the cooling and dehumidification tower is vertically arranged, the plate heat exchanger shell 6 is fixed above the cooling and dehumidification tower, the air outlet 10 of the dehumidification tower is connected with the cold air inlet 9 of the plate heat exchanger, and the plate heat exchanger The high temperature and humid air outlet 7 of the shell is connected to one end of the C-shaped air passage, and the other end of the air passage is connected to the dehumidification tower air inlet 18 located at the lower part of the cooling dehumidification tower.

[0025] The plate heat exchanger is composed of high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com