Acoustic meta-material scatterer and sound insulation device thereof

A technology of sound insulation devices and scatterers, applied in sound insulation, soundproof doors/windows, ventilation layout, etc., can solve problems such as only considering the amplification behavior of evanescent waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

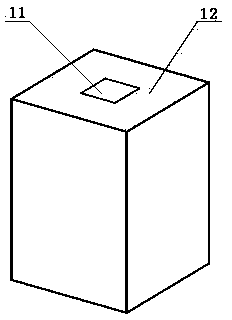

[0054] like Figure 5 As shown, the ultrasonic scatterer sound insulation device includes an ultrasonic scatterer and a frame structure. The frame structure is a window surrounded by frame 21. In this embodiment, the frame 21 is a wall. The inner contour of the frame structure is rectangular, and the length and width are L 1 and L 2 , the shell 12 of the ultrasonic scatterer is rectangular, and its length and width are respectively b 1 and b 2 , the inner core 11 of the ultrasonic scatterer is rectangular, and the length and width are respectively a 1 and a 2 The long side of the inner contour of the frame structure, the long side of the ultrasonic scatterer shell 12, and the long side of the ultrasonic scatterer inner core 11 are parallel to each other; the geometric center of the ultrasonic scatterer is the same as the inner contour geometric center of the frame structure. There is a ventilation area 3 between the ultrasonic scatterer and the frame structure. The son...

Embodiment 2

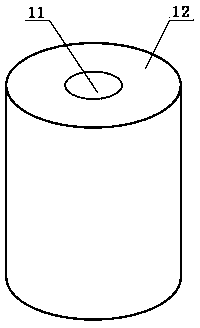

[0059] like Image 6 As shown, the ultrasonic scatterer sound insulation device includes an ultrasonic scatterer and a frame structure. The frame structure is a window surrounded by frame 21. The inner contour of the frame structure is a square, and the side length is L, and the shell 12 and the inner core 11 of the ultrasonic scatterer are all square, and the side length of the outer shell 12 is b, and the side length of the inner core 11 is a; The sides of the outer shell 12 of the superscatterer and the inner core 11 of the supersonic scatterer are parallel to each other; the geometric center of the supersonic scatterer is the same as the geometric center of the inner contour of the frame structure. There is a ventilation area 3 between the ultrasonic scatterer and the frame structure. The sonic diffuser is fixed in the center of the frame structure. The relationship between L, b, and a is satisfied: b 2 ≥ aL. The equivalent acoustic density ρ of the acoustic metamater...

Embodiment 3

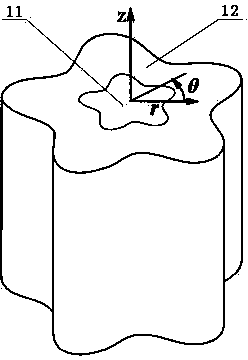

[0064] like Figure 7As shown, the ultrasonic scatterer sound insulation device includes an ultrasonic scatterer and a frame structure. The frame structure is a window surrounded by frame 21. The inner contour of the frame structure is a square, the side length is L, the cross section of the outer shell 12 and inner core 11 of the ultrasonic scatterer is circular, the diameter of the outer shell 12 is b, and the diameter of the inner core 11 is a. The geometric center of the acoustic superscatterer is the same as the geometric center of the inner contour of the frame structure. There is a ventilation area 3 between the ultrasonic scatterer and the frame structure. The sonic diffuser is fixed in the center of the frame structure. The relationship between L, b, and a is satisfied: The equivalent acoustic density ρ of the acoustic metamaterial for the shell of an acoustic superscatterer 1 and modulus κ 1 satisfy the equation:

[0065] [ρ 1 ,κ 1 ]=[-ρ,-κ(2r / b) 4 ].

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com