Micro-pore electroplated copper filling method for three-dimensional (3D) copper interconnection high aspect ratio through-silicon-via technology

A high-aspect-ratio, through-silicon via technology, applied in circuits, electrical components, electrolytic processes, etc., can solve problems such as holes left in the channel, and achieve the effect of easy maintenance and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

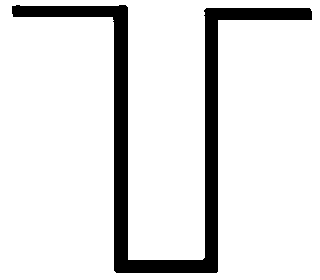

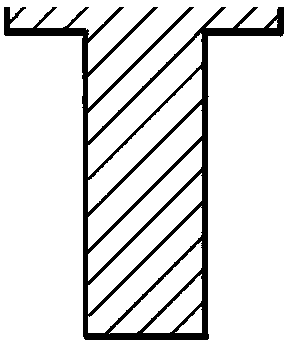

[0044] Take the 10×100μm hole pattern as an example.

[0045] Pretreatment conditions: under the condition of vacuum degree of 0~0.2 torr (torr), vacuumize for 5 minutes, soak in pure water for 1-10 minutes.

[0046] Proportion of copper methanesulfonate basic plating solution: 100g / L Cu 2+ , 30g / L ultra-pure methanesulfonic acid, and 30mg / L Cl - .

[0047] The additive ratio is accelerator: inhibitor: leveler=5:10:5.

[0048] Experimental conditions: temperature = 25 ℃, flow rate = 15 L / min, cathode rotation speed = 50 RPM.

[0049] Electroplating parameters: 0.01ASD 120s; 0.1ASD 600s; 0.4ASD 3000s.

[0050] Result: if image 3 As shown, it is completely filled, without defects, and the surface copper thickness is <3μm.

Embodiment 2

[0052] Take the 15×150μm hole pattern as an example.

[0053] Pretreatment conditions: under the condition of vacuum degree of 0~0.2 torr, vacuumize for 5 minutes, soak in pure water for 1-10 minutes.

[0054] Proportion of copper methanesulfonate basic plating solution: 90g / L Cu 2+ , 20g / L of ultra-pure methanesulfonic acid, and 20mg / L of Cl - .

[0055] The additive ratio is accelerator:inhibitor:leveler=3:10:7.

[0056] Experimental conditions: temperature=22-25 ℃, flow rate=15 L / min, rotation speed=50 RPM.

[0057] Plating parameters: 0.01ASD 120s; 1.0ASD 300s; 0.7ASD 600s; 0.5ASD 2400s; 0.7ASD 300s; 0.3ASD 1200s.

[0058] Result: if Figure 4 As shown, completely filled with no defects.

[0059] Post-plating treatment: Rinse the wafer with deionized water for 2 minutes and dry it.

[0060] The electroplating samples of embodiment one and embodiment two gained are analyzed and tested and evaluated:

[0061] 1. Cross-section analysis: Slice the electroplated sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com