Production method for effectively controlling gas content in beam blank

A technology of gas content and production method, which is applied in the direction of manufacturing converters, etc., can solve the problems of undiscovered special-shaped billets and the difficulty of controlling the quality of the casting billet of the special-shaped billet continuous casting machine, so as to reduce pinhole defects, improve the purity of molten steel, reduce Effect of H content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

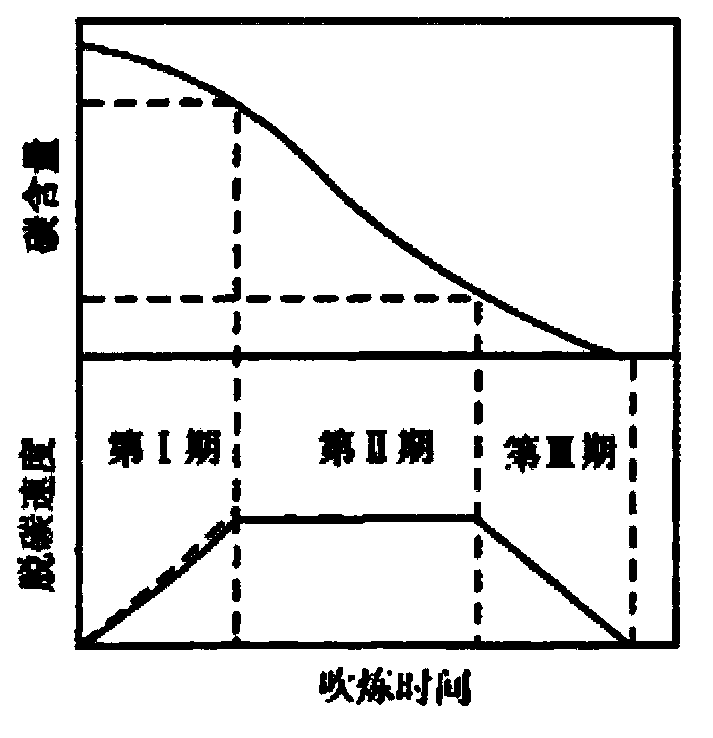

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: smelting Q235B steel

[0036] (1) The raw material workshop strengthens material control to ensure that the materials used for production must be kept dry. The main measures are as follows: 1) Before the alloy material enters the baking room, it needs to be baked at a high temperature in an advanced baking kiln, and the baking temperature is 300-400°C; 2) Lime is easy to be affected by moisture, and it is stored in a silo by a circular feeding method. The period is less than 24 hours; 3) The scrap steel into the furnace is added in advance, and the scrap steel is baked by using the temperature in the furnace for 4 minutes; 4) The remaining materials include synthetic slag for converters, carburizers, and rice husks for refining , recarburizer, mold slag for continuous casting, etc., all need to be baked in the baking room before use, and the temperature of the baking room reaches 55-65 °C. (2) Steel scrap is added 2 minutes before converter smelting, then...

Embodiment 2

[0037] Embodiment 2: smelting steel grade Q235B

[0038] Using the same process as in Example 1, the difference is: in step (4), refining 2.0ppm of inbound hydrogen and 2.4ppm of outbound hydrogen.

Embodiment 3

[0040] The smelting steel type Q235B and the process method are the same as those in Example 1, except that the inbound hydrogen for refining is 2.0ppm, and the outbound hydrogen is 2.3ppm.

[0041] The following is an example of smelting Q235B steel according to the existing traditional technology for comparison.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com