Constant current diffused protein crystallization method, open type constant current diffused protein crystallization array chip and manufacture method and application of chip

A protein crystallization and array chip technology, which is applied in the biological field, can solve problems such as difficulty in promoting protein molecular crystallization, limited total amount of protein molecules, small protein crystal volume, etc., to achieve convenient extraction or analysis, high crystal cluster density, and crystal size big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

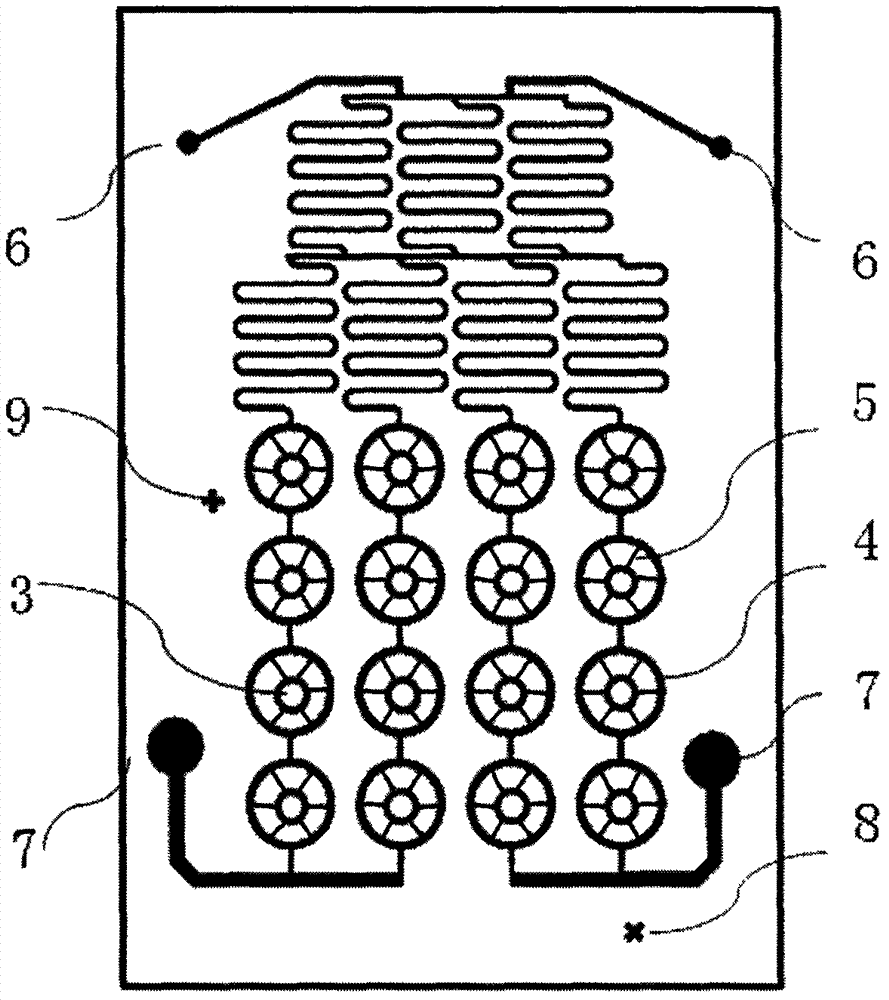

[0046] Example 1: Figure 1-6 Shown is the first preferred embodiment of the constant current diffusion protein crystallization method and the open constant current diffusion protein crystallization array chip of the present invention. The open constant current diffusion protein crystallization array chip contains 4×4 protein crystallization units, and the basic material uses porous polydimethylsiloxane (PDMS), and its preparation adopts the following steps:

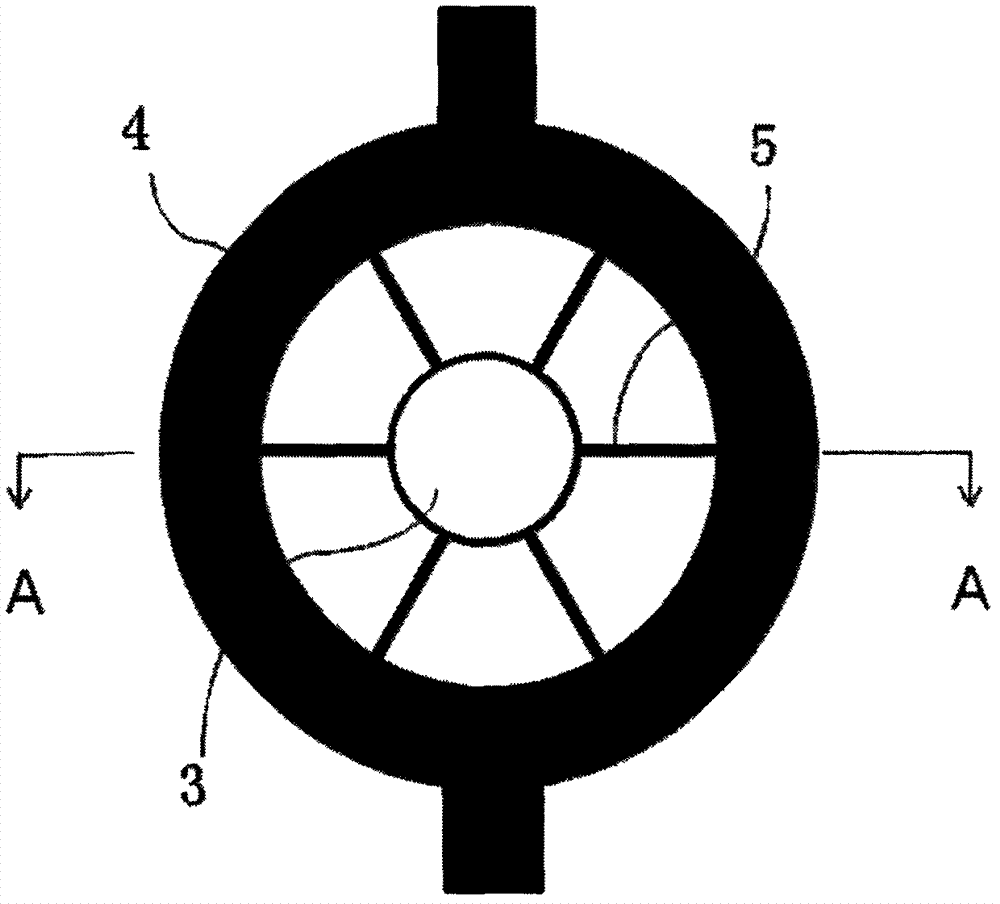

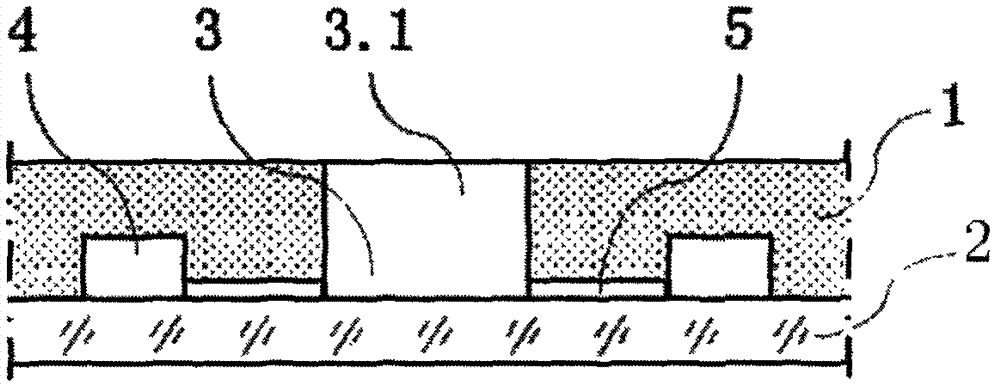

[0047] 1) Draw with L-Edit and make such as Figure 4 and Figure 5 The optical template: mainly includes two parts:

[0048] Figure 5 Main channel design drawing, Figure 6 Design diagrams for diffusion channels. Wherein, the width of the main channel is 100 microns, and the width of the diffusion channel is 5 microns.

[0049] 2) Fabrication of the mold for the design pattern: the silicon wafer was ultrasonically cleaned with isopropanol and acetone for 5 minutes respectively, and boiled with a mixture of concen...

Embodiment 2

[0054] Example 2: Figure 1-6 As shown, the constant current diffusion protein crystallization method of the present invention and the open constant current diffusion protein crystallization array chip are used for the screening test of lysozyme protein crystallization conditions, and the following steps are adopted:

[0055] 1) Configure 20 mg / ml and 120 mg / ml lysozyme protein solutions, and use a circulating syringe pump to simultaneously feed these two protein aqueous solutions into the liquid inlet, and the injection speed is set to 8 μl / min.

[0056] 2) After the diffusion tube of the chip is filled with protein solution, add NaCl solution and CH to 16 crystallization units according to different concentration conditions. 3 COONa / CH 3 COOH mixed solution (the typical concentration range of NaCl is 0.5 mol / L-4 mol / L, CH 3 COONa / CH 3 The ratio range of the COOH mixed solution is 1:1-10:1).

[0057] 3) Continue to pass through the protein aqueous solution at an injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com