Combined process for preparing poly methoxy-dimethyl ether

A technology of polyoxymethylene dimethyl ether and combined process, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems such as difficult separation of formaldehyde, and achieve simple equipment, suitable for industrialization promotion, and process Reasonable effect of process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

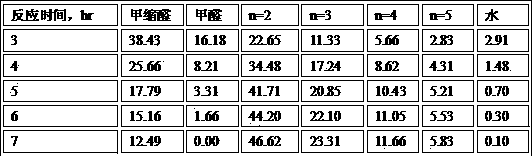

[0021] Put 600 grams of acidic ion exchange resin, 2,700 grams of paraformaldehyde, and 3,700 grams of methylal into the reactor respectively, slowly heat to 150°C for 3 hours, then pump the reaction solution into the membrane separation dehydrator at 12 L / hr, and put The water in the reaction solution was removed and then returned to the reactor, and samples were taken from the reactor every 1 hour to analyze the composition of reactant grade products in the system. The results are shown in Table 1.

[0022] Table 1

[0023]

Embodiment 2

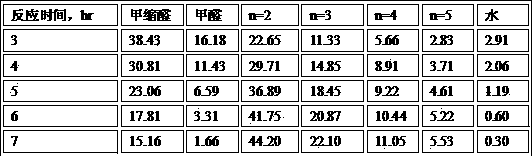

[0025] Put 600 grams of acidic ion exchange resin, 2,700 grams of paraformaldehyde, and 3,700 grams of methylal into the reactor respectively, and slowly heat to 150°C for 2 hours at a constant temperature, then pump the reaction liquid into the membrane separation dehydrator at 8 L / hr. The water in the reaction solution was removed and then returned to the reactor, and samples were taken from the reactor every 1 hour to analyze the composition of reactant grade products in the system. The results are shown in Table 2.

[0026] Table 2

[0027]

Embodiment 3

[0029] Put 600 grams of acidic ion exchange resin, 2,700 grams of paraformaldehyde, and 3,700 grams of methylal into the reactor respectively, and slowly heat to 150°C for 2 hours at a constant temperature, then pump the reaction liquid into the membrane separation dehydrator at 6 L / hr, and put The water in the reaction solution was removed and then returned to the reactor, and samples were taken from the reactor every 1 hour to analyze the composition of reactant grade products in the system. The results are shown in Table 3.

[0030] table 3

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com