Novel preparation method of mesoporous active carbon

A mesoporous activated carbon and surfactant technology, applied in chemical instruments and methods, bulk chemical production, inorganic chemistry, etc., can solve the problems of poor thermal stability and high content of porous carbon functional groups, and achieve good thermal stability , easy recycling, low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 2g of glucose and add it to 20g of 1-butylsulfonic acid-3-methylimidazolium bisulfate, dissolve at 60°C for 30min, heat to 150°C for carbonization for 5h, and obtain a solid that is washed and dried to obtain primary activated carbon. The primary activated carbon yield was 37.8%, and its elemental composition was: C, 61.22%; H, 4.33%; O, 32.31%; S, 1.57%; N, 0.38%. Then the primary activated carbon was placed in a tubular carbonization furnace, and CO was introduced at a flow rate of 15ml / min. 2 The air was replaced for 15 min, and then heated to 500 °C for 2 h at a heating rate of 10 °C / min to obtain mesoporous activated carbon with a yield of 54.7% of the primary activated carbon sample, and its elemental composition was: C, 85.24%; H, 3.08%; O , 10.00%; S, 0.10%; N, 0.28%.

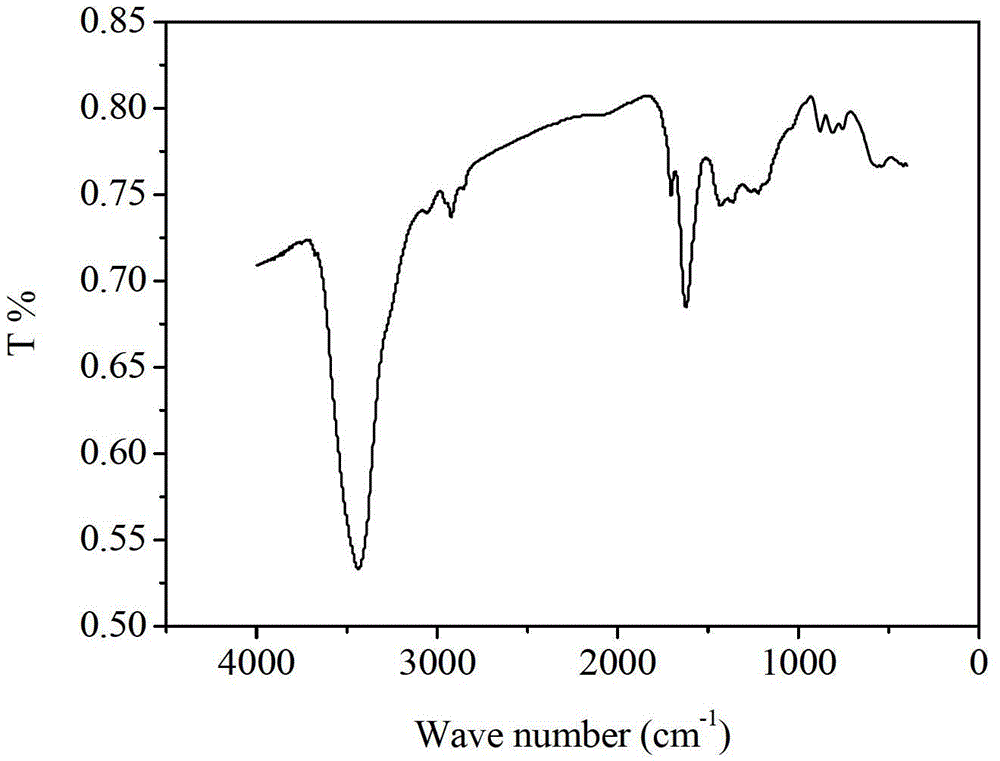

[0030] The specific surface area analysis results show that the specific surface area of the obtained mesoporous activated carbon is 454m 2 / g, the pore size is 3.55nm. Raman spectrosc...

Embodiment 2

[0032] Repeat Example 1, with the following differences: the selected starting material is cellulose, and the obtained primary activated carbon yield is 50.4%, and its elemental composition is: C, 61.66%; H, 4.78%; O, 32.25%; S , 1.85%; N, 0.77%. Then the primary activated carbon is activated by the same method as in Example 1 to obtain mesoporous activated carbon, the yield is 54.7% of the primary activated carbon sample, and its elemental composition is: C, 84.88%; H, 3.65%; O, 11.19%; S, 0.17 %; N, 0.58%. The specific surface area analysis results show that the specific surface area of the obtained mesoporous activated carbon is 465m 2 / g, the pore size is 3.58nm.

Embodiment 3

[0034] Repeat Example 1, with the following differences: the selected starting material is lignin, and the obtained primary activated carbon yield is 28.8%, and its elemental composition is: C, 55.33%; H, 5.12%; O, 30.70%; S , 6.10%; N, 2.45%. Then the primary activated carbon is activated by the same method as in Example 1 to obtain mesoporous activated carbon, the yield is 50.4% of the primary activated carbon sample, and its elemental composition is: C, 84.45%; H, 2.95%; O, 10.19%; S, 0.14 %; N, 0.58%. The specific surface area analysis results show that the specific surface area of the obtained mesoporous activated carbon is 289m 2 / g, the pore size is 3.58nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com