Tank transport vehicle and its internal shut-off valve device

A technology of shut-off valve and transport vehicle, applied in valve device, transportation and packaging, valve operation/release device, etc., can solve the problems of potential safety hazards and increase in the weight of the transport vehicle, so as to reduce liquid sloshing, reduce self-weight, improve The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0015] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

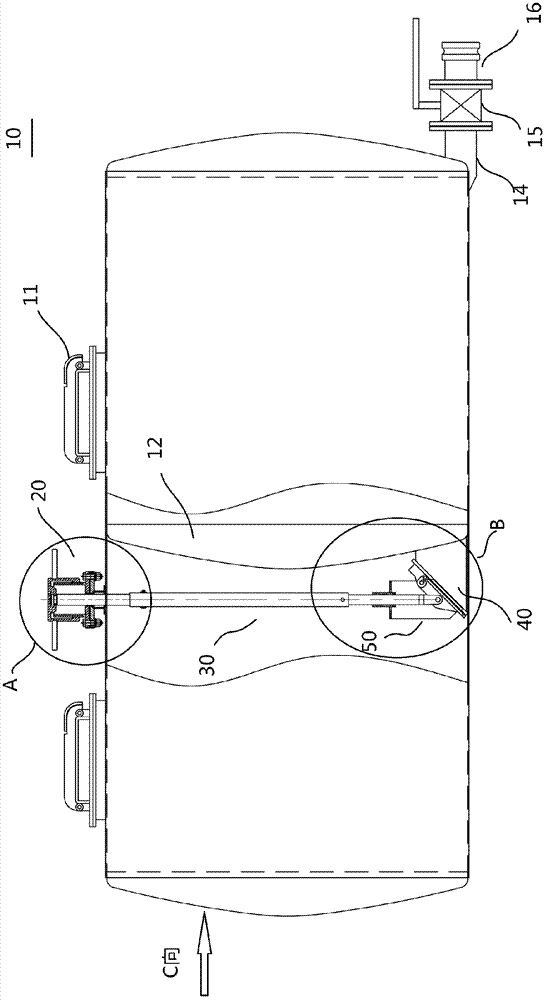

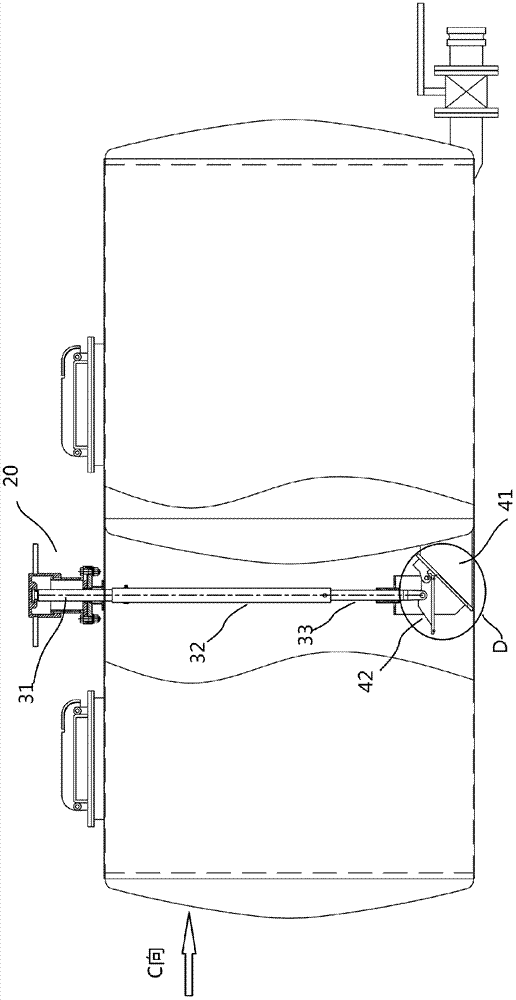

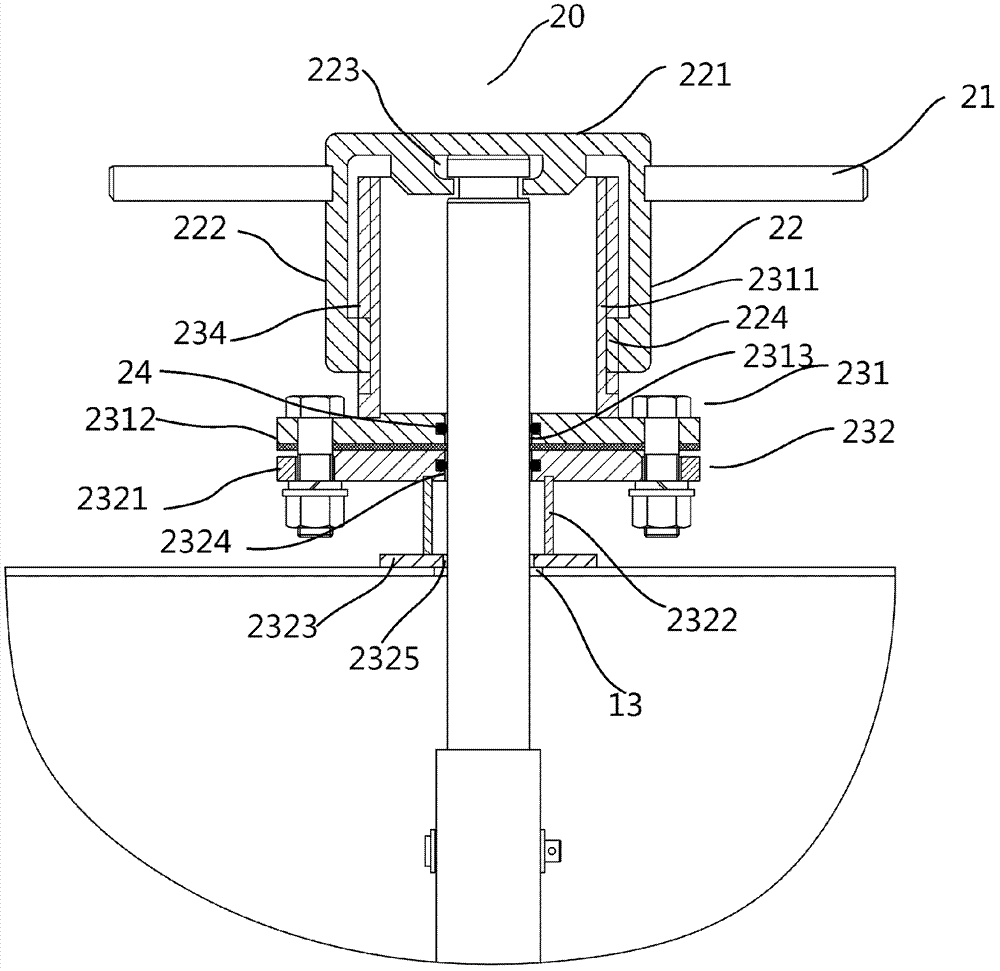

[0016] Such as figure 1 As shown, the tank body 10 of the tank transport vehicle includes: an installation manhole 11 provided at the top, through which the inside of the tank body 10 can be charged; a compartment plate 12, through which the tank body 10 Divided into a plurality of compartments, the bottom of the compartment plate 12 is provided with diversion holes (not shown), the compartment plate 12 can be a flat plate, a corrugated plate or a drum-shaped plate; and an internal shut-off valve device.

[0017] The internal shut-off v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com