Cutting machine

A technology for cutting machines and guards, which is applied in the direction of metal sawing equipment, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of unfavorable movement, disassembly and installation, potential safety hazards, time-consuming and labor-intensive, etc., and achieves easy grip And the effect of picking up and putting down, convenient operation, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

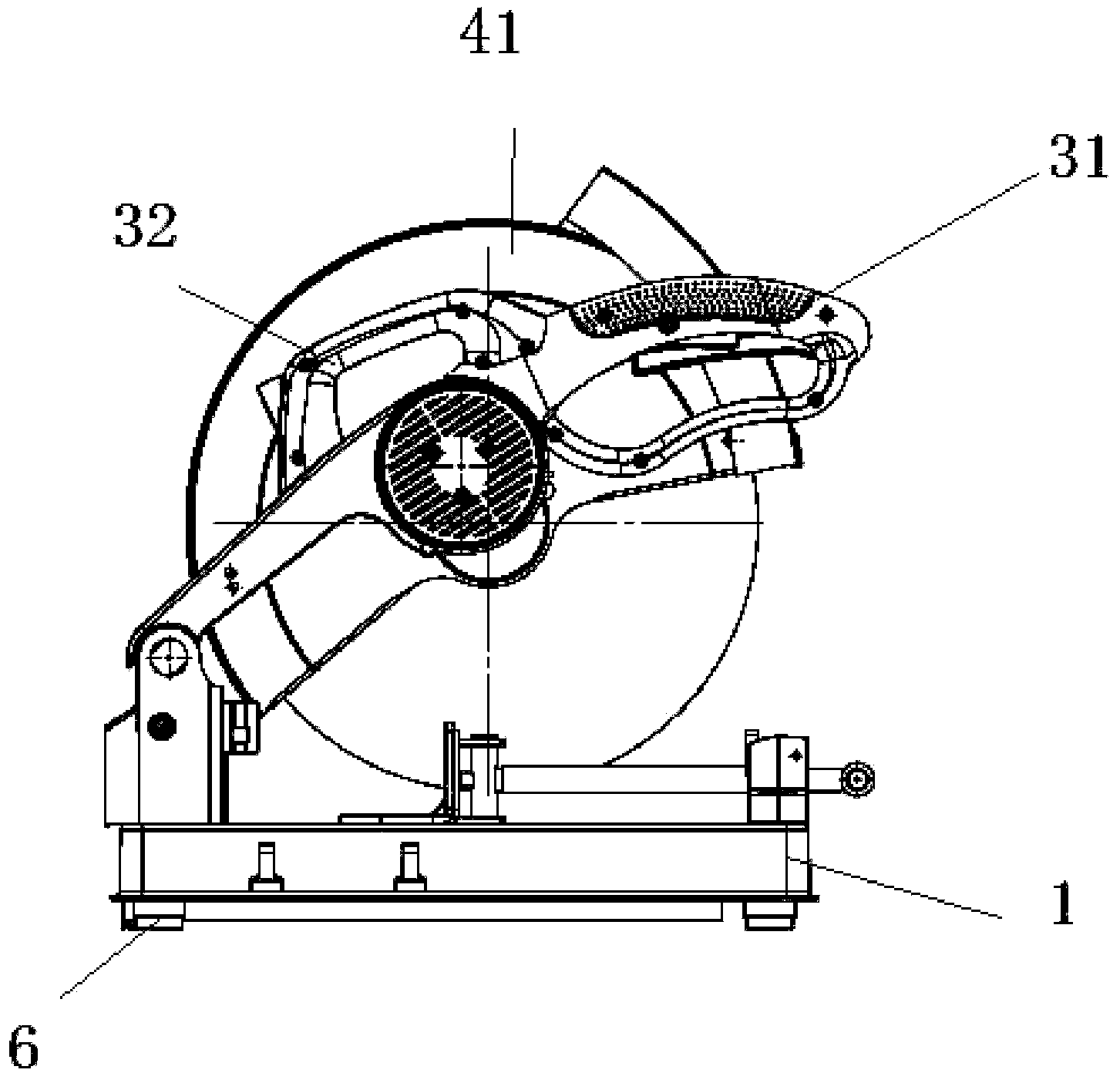

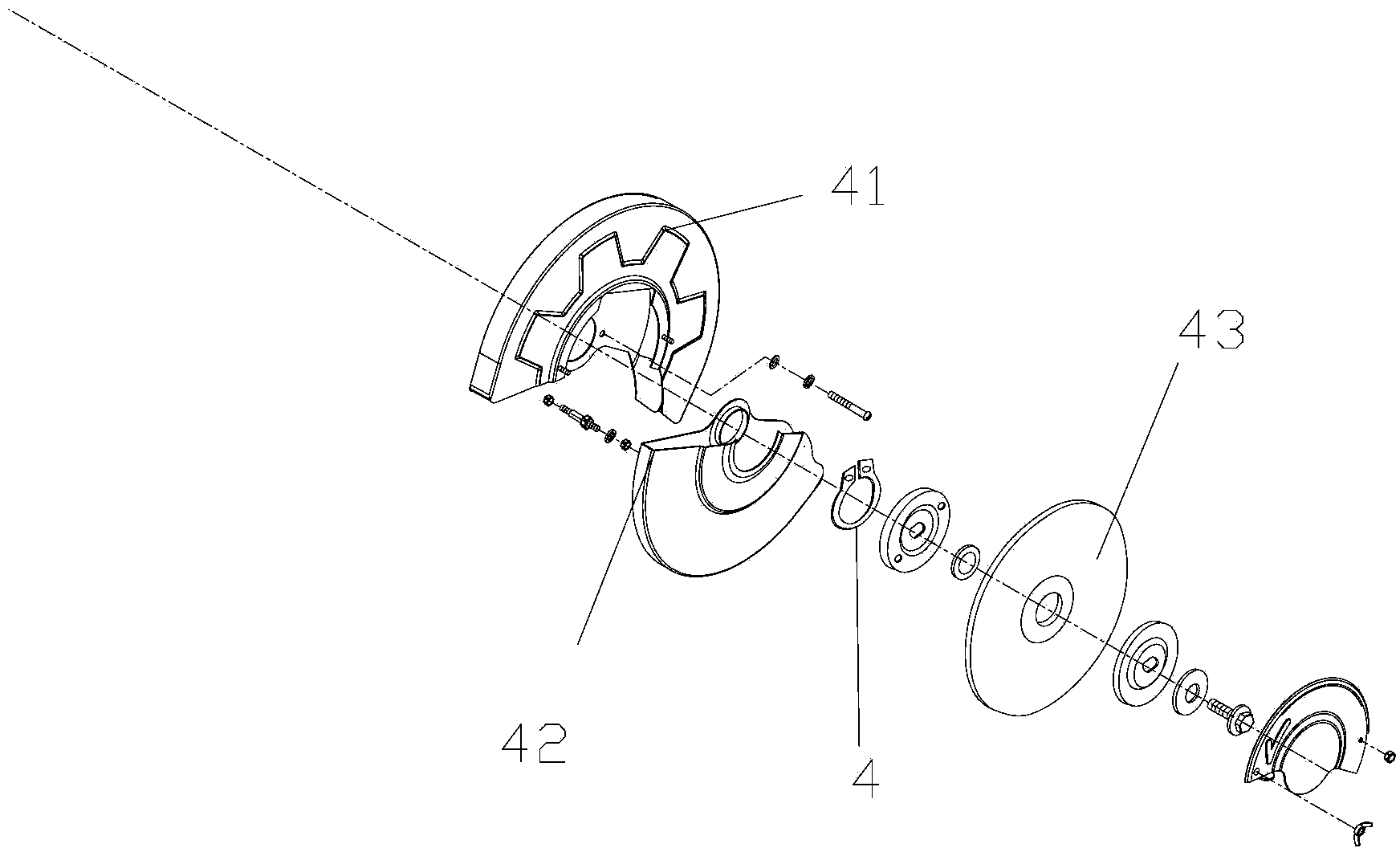

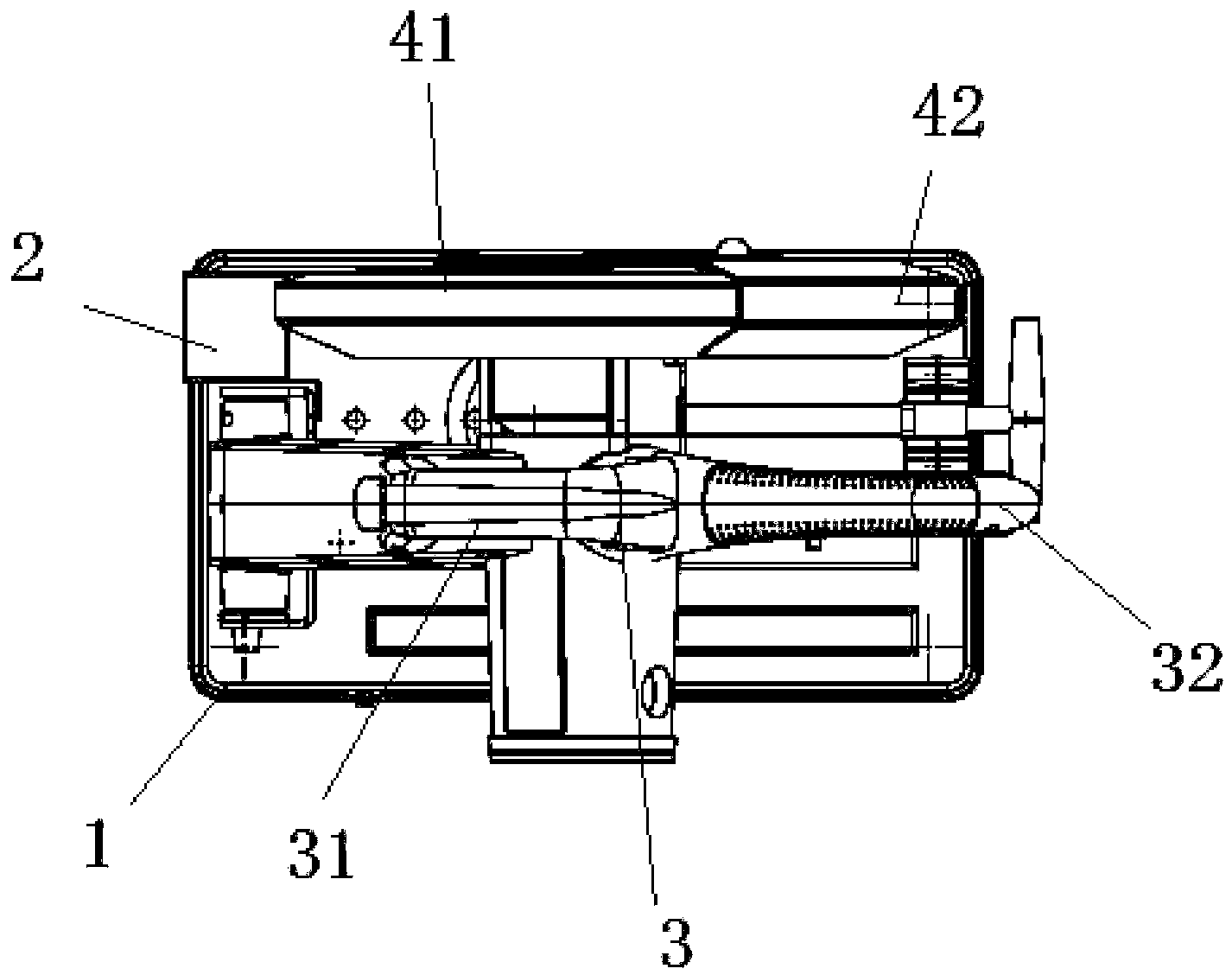

[0014] Such as Figure 1 to Figure 4 As shown, a cutting machine of the present invention includes a base 1, a fixed block 2 mounted on the base 1 and a handle device 3, one side of the fixed block 2 is connected to the end of the support block, and the top of the support block is provided with an arc shaped connecting rod, the saw blade assembly 4 is fixed on the connecting rod; the saw blade assembly 4 includes a first guard 41, a second guard 42 and a grinding wheel sheet 43, and the second guard 42 is equipped with a grinding wheel 43 inside , a first shield 41 is sheathed on the outside, and a driving device connected to the grinding wheel piece 43 is installed on one side of the first shield 41 .

[0015] As a preference, the first shield 41 and the second shield 42 are flexibly connected, and both the first shield 41 and the second shield 42 are open semicircul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com