Method for stamping multi-station progressive die

A multi-station and manufacturing method technology, applied in the field of die punching, can solve the problems affecting the punching accuracy of products, traction error, increase die material, etc., and achieve the effect of reducing two-way traction links, improving manufacturing accuracy, and reducing manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

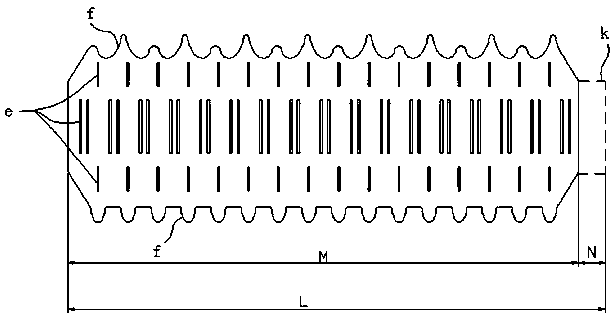

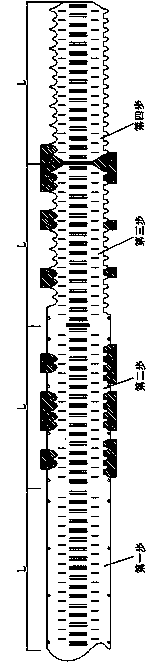

[0015] The method of the present invention is illustrated by taking the punched product with material as an example. figure 1 As shown, the structural features of this product are divided into two types: the narrow and long groove e in the middle part and the regular and irregular toothed f in the outer contour part. In the punching method, the feeding step of the punching strip is L, and L is the length M of the product plus the length N of the edge. When designing the mold, such as image 3 As shown, the narrow and long groove e is divided into two features, that is, feature a1 and feature a2. For regular and irregular tooth shapes f, starting from the requirements of mold processing technology, it is divided into seven features such as feature a3-feature a9. Among them, feature a5 is the part that needs to be cut off caused by the vertical edge (ie, process waste), and the remaining features a3, a4, a6-a9 are the parts that need to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com