Processing method of vacuum refrigerating flavored prawn cake

A technology of vacuum freezing and processing methods, applied in the field of food processing, which can solve the problems of inconvenient transportation, insufficient nutrition, comprehensiveness, and high transportation costs, and achieve flavor and taste retention, rich nutrition, and good appearance and color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

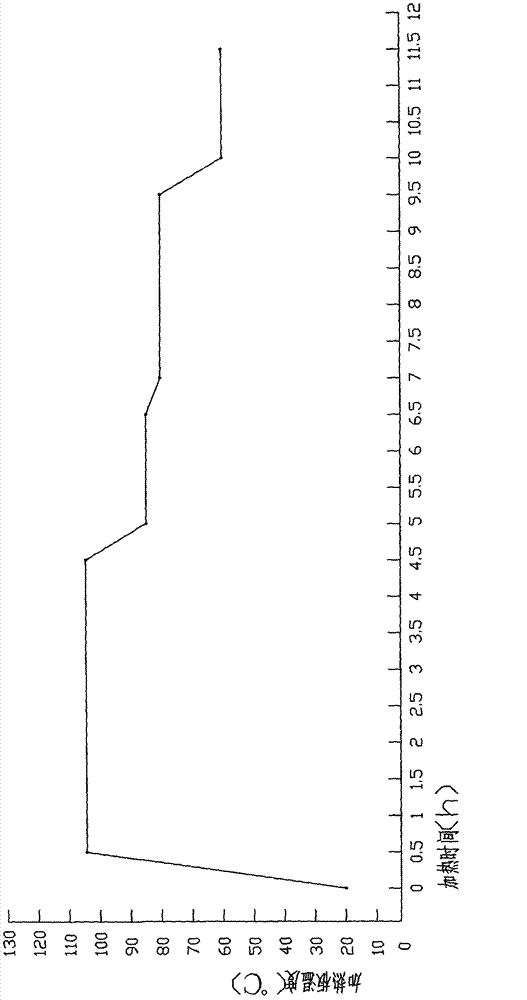

[0032] Depend on figure 1 Shown, a kind of processing method of vacuum freeze-dry flavor shrimp cake, concrete processing method is as follows:

[0033] a. Material selection: select raw materials in the following proportions by weight: minced fish 70, shelled shrimp 30, soybean protein isolate 9, and shrimp meat paste 4. The minced fish must be well frozen and have no peculiar smell;

[0034] b. Pretreatment: Cut the frozen surimi into small pieces with a knife and put them in an environment of 0°C-4°C for later use;

[0035] c. Beating: put the frozen surimi block, shrimp, soybean protein isolate and shrimp meat paste together in the beater, then add the seasoning into the beater and beat at high speed until the minced meat is uniform, and control the temperature of the slurry during the beating process Below 12°C, the proportioning by weight of the added seasoning is: 2.2 portions of salt, 0.5 portions of monosodium glutamate, 0.08 portions of ginger powder, 0.08 portions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com