Wet method polyurethane resin for clothing leather, and preparation method thereof

A technology for wet-process polyurethane and garment leather is applied in the field of wet-process polyurethane resin for garment leather and its preparation, which can solve the problems of poor hand feel, softness and high cost, and achieve the effects of plump hand feel, sufficient supply of raw materials and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

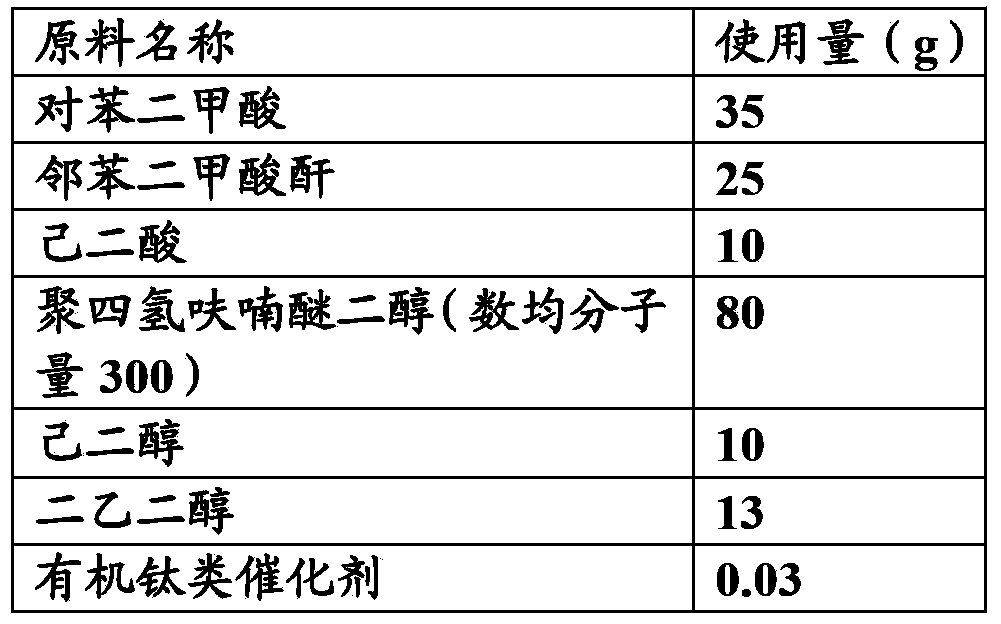

[0025] This example provides a kind of ester-ether copolymer polyol, its raw material formula sees Table 1:

[0026] Table 1

[0027]

[0028] The preparation method of ester-ether copolymer polyol is as follows: Add various raw materials in Table 1 into a four-necked round-bottomed flask equipped with mechanical stirring, nitrogen, temperature controller, and condensation reflux equipment, and gradually raise the temperature to 220°C for 15 hours and then test The acid value of the product is 0.45mgKOH / g, and the hydroxyl value is 15.5mgKOH / g, then cooled for later use.

Embodiment 2

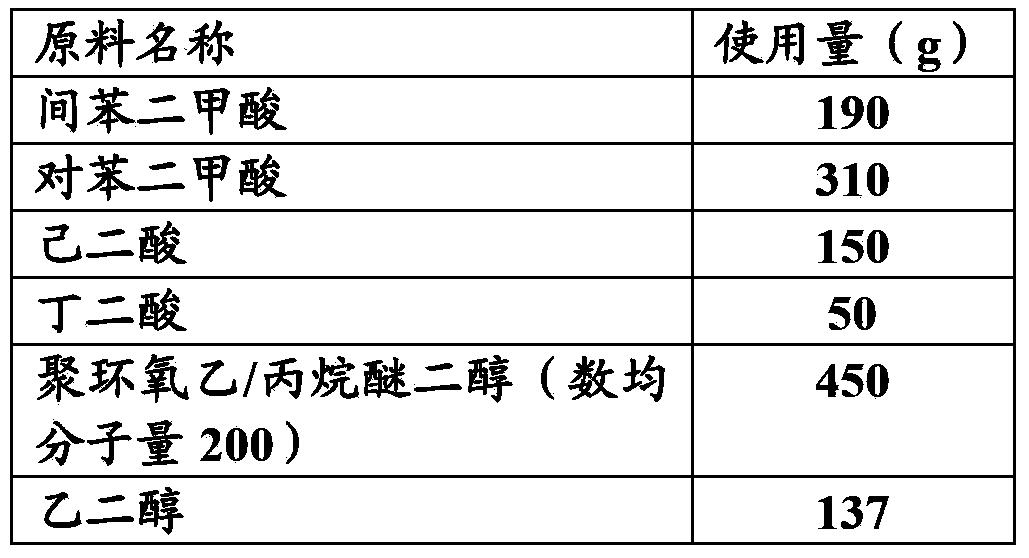

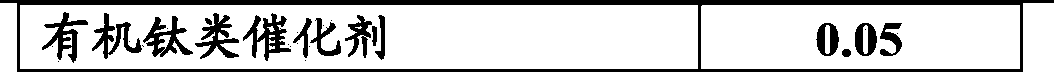

[0030] This example provides a kind of ester ether copolymer polyol, and its raw material formula sees Table 2:

[0031] Table 2

[0032]

[0033]

[0034] The preparation method of ester-ether copolymer polyol is as follows: Add various raw materials in the table into a four-necked round-bottomed flask equipped with mechanical stirring, nitrogen, temperature controller, and condensation reflux equipment, and gradually raise the temperature to 225°C for 18 hours to test the product After the acid value is 0.35mgKOH / g and the hydroxyl value is 18.5mgKOH / g, the temperature is lowered for later use.

Embodiment 3

[0036] This example provides a kind of ester ether copolymer polyol, and its raw material formula sees Table 3:

[0037]

[0038]The preparation method of ester-ether copolymer polyol is as follows: Add various raw materials in the table into a four-neck round-bottomed flask equipped with mechanical stirring, nitrogen, temperature controller, and condensation reflux equipment, and gradually raise the temperature to 230°C for 17 hours to test the product After the acid value is 0.39mgKOH / g and the hydroxyl value is 14.8mgKOH / g, the temperature is lowered for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com