Standard preparation technology for root carving product

A production process and product format technology, applied in the process of producing decorative surface effects, decorative arts and other directions, can solve the problems of unsuitable production process, incompatibility, discoloration of roots, etc., and achieves environmental protection and strong versatility. , the effect of less material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

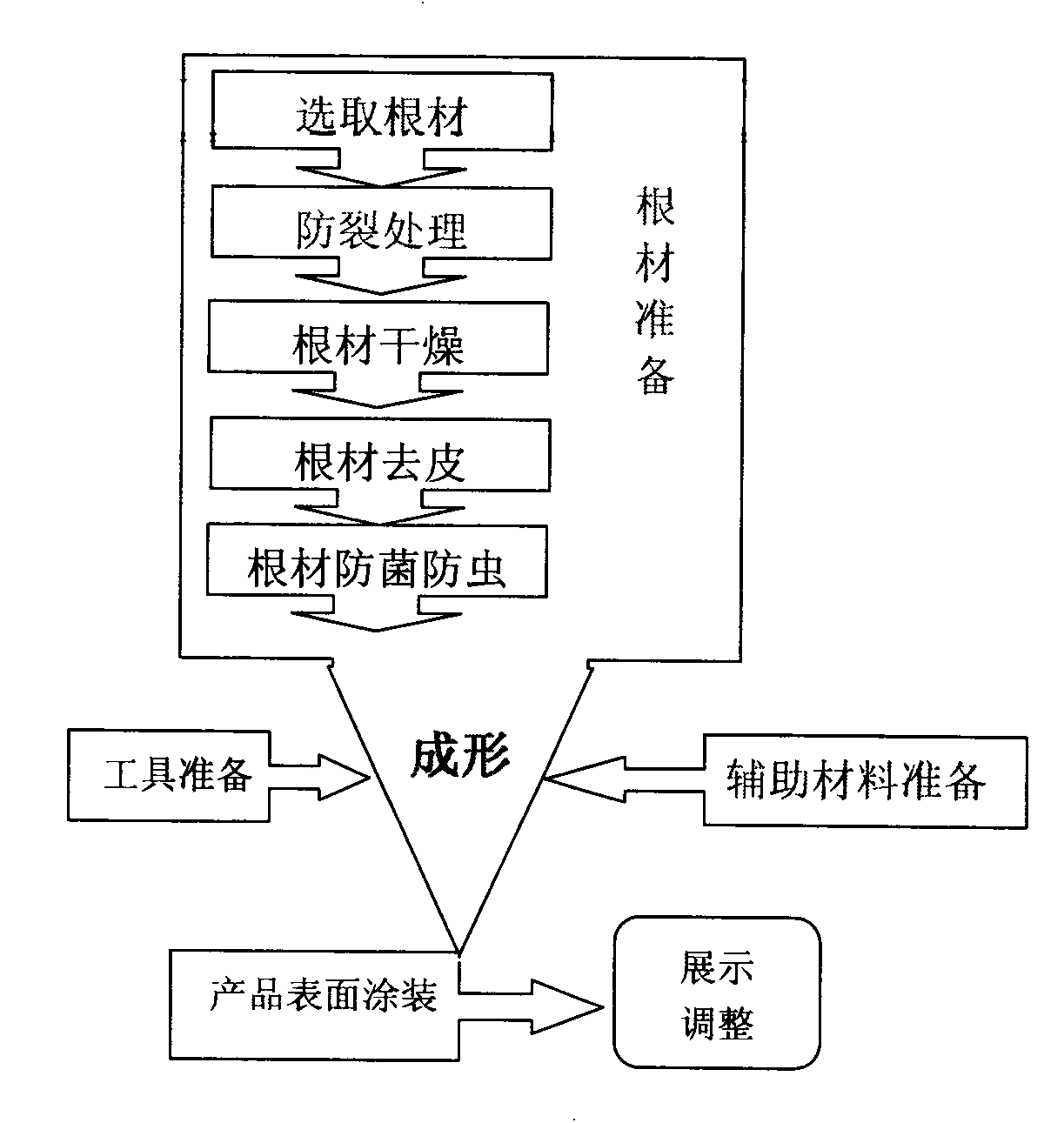

[0028] The invention includes six steps: root material preparation, tool preparation, auxiliary material preparation, molding, product surface coating and display adjustment.

[0029] Among them, root material preparation includes root material selection, anti-cracking treatment, root material drying, root material peeling and root material antibacterial and insect control.

[0030] Among them, the preparation of tools includes saws, rasps, chisels, carving knives, flat shovels, axes, augers, wooden hammers, planes, in addition to scissors for pruning, knives, brushes, sandpaper, and coarse cloth , cotton yarn, rope.

[0031] Among them, the preparation of auxiliary materials includes water glue or latex, paraffin, and paint including varnish, raw lacquer, and paint flakes; when coloring is required, the required pigments must also be prepared.

[0032] In the above, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com