Regeneration method of nitrogen-preparation carbon molecular sieve

A carbon molecular sieve and molecular sieve technology, applied in the field of regeneration of nitrogen-producing carbon molecular sieve, can solve the problems of large pores, uneven pore size of carbon molecular sieve, poor activation effect, etc., and achieve high adsorption capacity, improve selectivity, and reduce the effect of pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

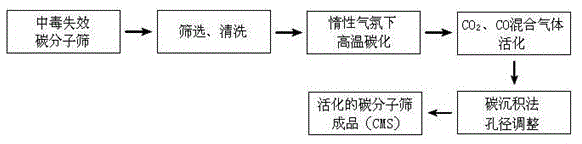

[0034] like image 3 As shown, the poisoned carbon molecular sieve of CMS-200 specification is screened through a 15-30 mesh screen, and then the screened carbon molecular sieve is washed 2-3 times with water to remove impurities; the cleaned carbon molecular sieve is placed in the furnace, Under the protection of nitrogen, the temperature is raised to 850°C for carbonization; mixed gas activation: after high temperature carbonization, CO is introduced into the furnace 2 , CO mixed gas, where CO 2 The ratio is 85%, and the carbonized carbon molecular sieve is activated, and the temperature in the furnace is 700°C; Toluene is fed through a precision peristaltic pump with a feeding flow rate of 50ml / min. Keep the furnace temperature at 300°C to allow carbon molecular sieves to adsorb xylene, and then crack xylene at 800°C to deposit pyrolytic carbon on the carbon material. Carbon molecular sieves are adjusted in pore size to obtain recycled products.

[0035] Since the gas pr...

Embodiment 2

[0039] like image 3 As shown, the poisoned carbon molecular sieve of CMS-280 specification is screened through a mesh screen, and then the screened carbon molecular sieve is washed 2-3 times with water to remove impurities; the cleaned carbon molecular sieve is placed in the furnace, under the protection of nitrogen Raise the temperature to 1000°C for carbonization; mixed gas activation: after high temperature carbonization, pass CO into the furnace 2 , CO mixed gas, where CO 2 The ratio is 90%, and the carbonized carbon molecular sieve is activated, and the temperature in the furnace is 800 °C; the activated carbon molecular sieve is placed in the converter furnace, and the temperature of the converter is 900 °C, and xylene is introduced under the protection of nitrogen. Toluene is fed through a precision peristaltic pump with a feeding flow rate of 80ml / min. Keep the furnace temperature at 500°C to allow carbon molecular sieves to adsorb xylene, and then crack xylene at 90...

Embodiment 3

[0042] like image 3 As shown, the poisoned carbon molecular sieve of CMS-240 specification is screened through a mesh screen, and then the screened carbon molecular sieve is washed 2-3 times with water to remove impurities; the cleaned carbon molecular sieve is placed in the furnace, under the protection of nitrogen Raise the temperature to 900°C for carbonization; mixed gas activation: after high-temperature carbonization, pass CO into the furnace 2 , CO mixed gas, where CO 2 The proportion is 88%, and the carbonized carbon molecular sieve is activated, and the temperature in the furnace is 78 °C; the activated carbon molecular sieve is placed in the converter furnace, and the temperature of the converter is 850 °C, and xylene is introduced under the protection of nitrogen. Toluene is fed through a precision peristaltic pump with a feeding flow rate of 66ml / min. Keep the furnace temperature at 400°C to allow carbon molecular sieves to adsorb xylene, and then crack xylene at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com