LED driving circuit

A technology of LED driving and driving control circuit, applied in the field of electronics, can solve the problems such as damage to the driving chip U1, poor safety, and increase of use cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

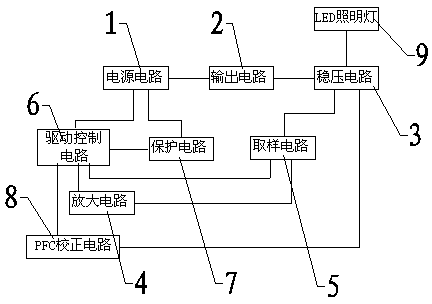

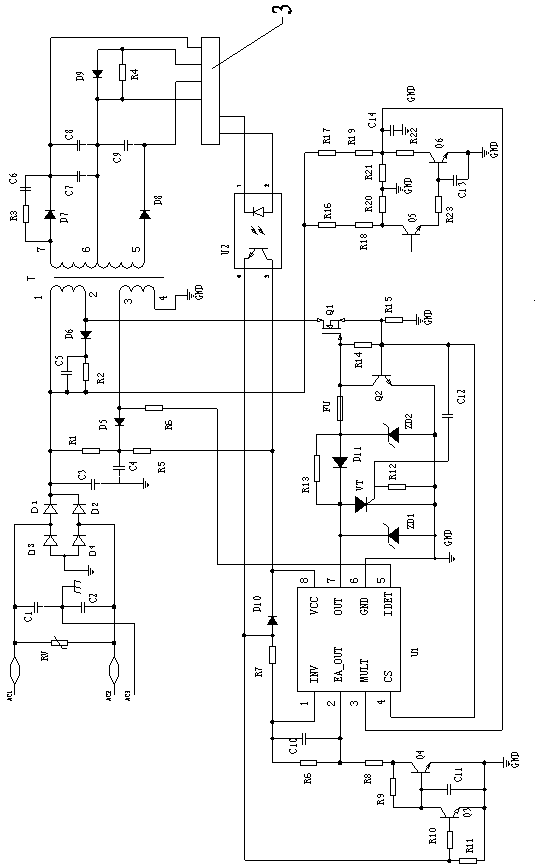

[0039] Examples such as figure 2 , image 3 As shown, an LED driving circuit includes a power supply circuit 1 , an output circuit 2 , a voltage stabilizing circuit 3 , an amplifying circuit 4 , a sampling circuit 5 , a driving control circuit 6 , a protection circuit 7 and a PFC correction circuit 8 .

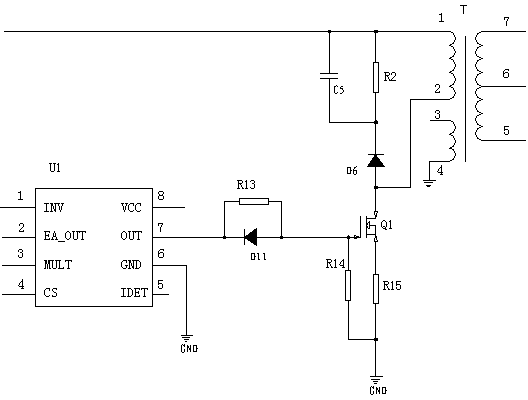

[0040] The power supply circuit 1 includes diode D1, diode D2, diode D3, diode D4, diode D5, diode D6, resistor R1, resistor R2, capacitor C1, capacitor C2, capacitor C3, capacitor C4, capacitor C5 and switching transformer T, diode D1, The rectifier bridge composed of diode D2, diode D3, and diode D4, the switching transformer T has a first primary coil, a second primary coil and a secondary coil, the capacitor C3 is connected between the positive pole of the rectifier bridge and the ground, and one end of the resistor R1 is connected to the rectifier The positive pole of the bridge, the other end of the resistor R1 is connected to one end of the capacitor C4, the negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com