Multi-frequency plane printed antenna comprising protruded floor and applied to mobile terminal

A mobile terminal and floor technology, which is applied in the direction of antenna, antenna grounding device, antenna grounding switch structure connection, etc., can solve the problems of antenna performance deterioration and achieve the effect of reducing processing and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

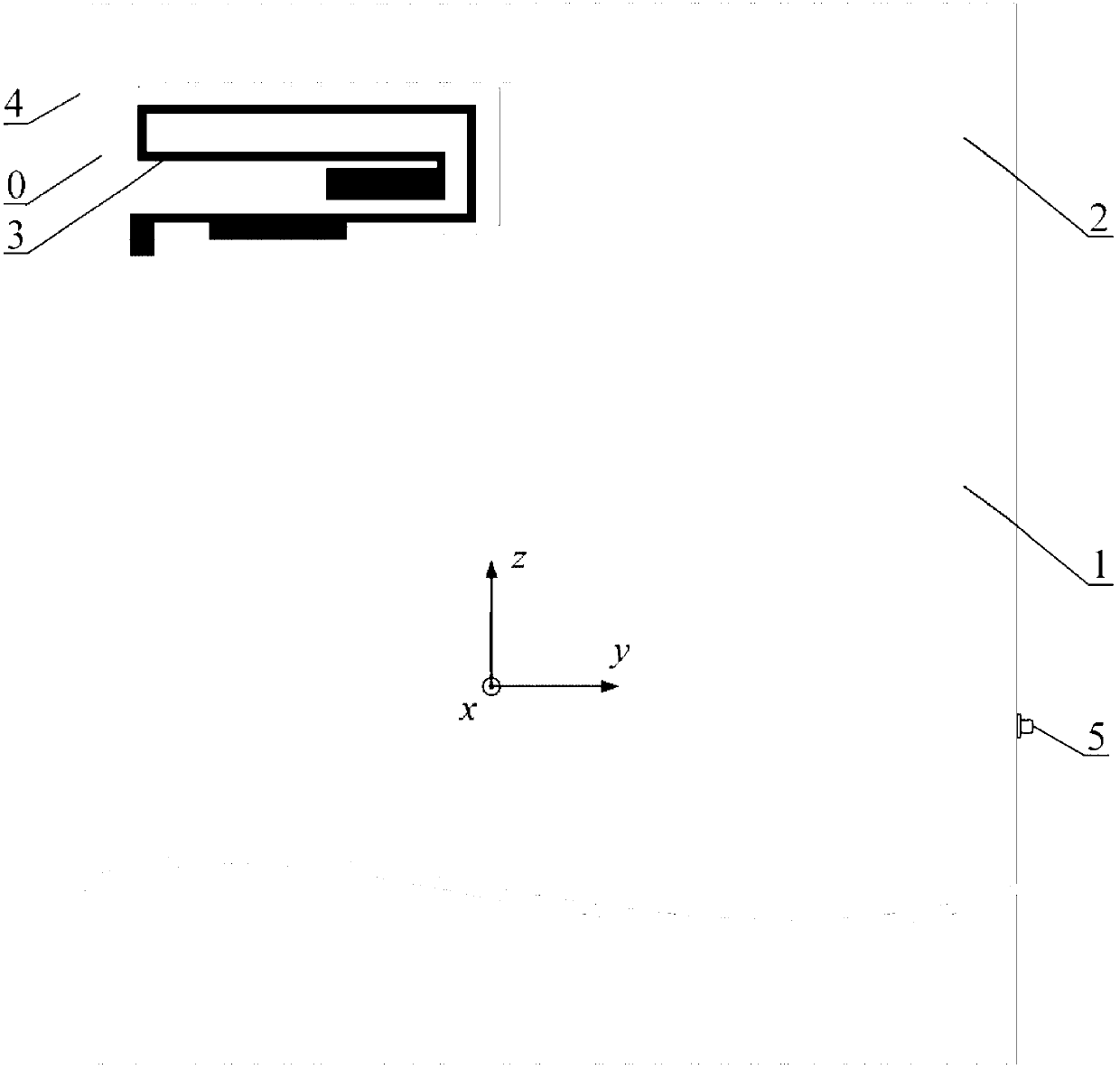

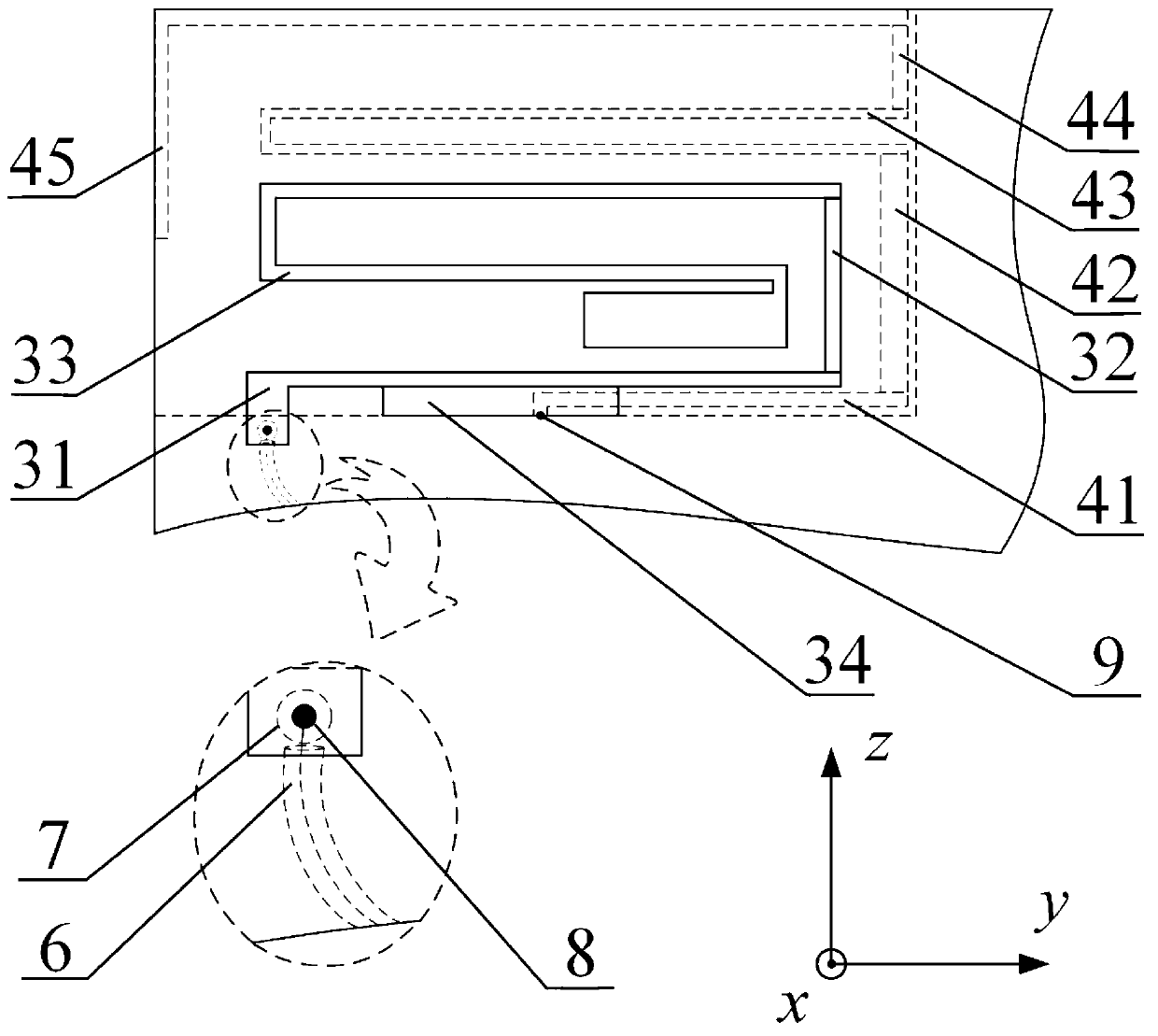

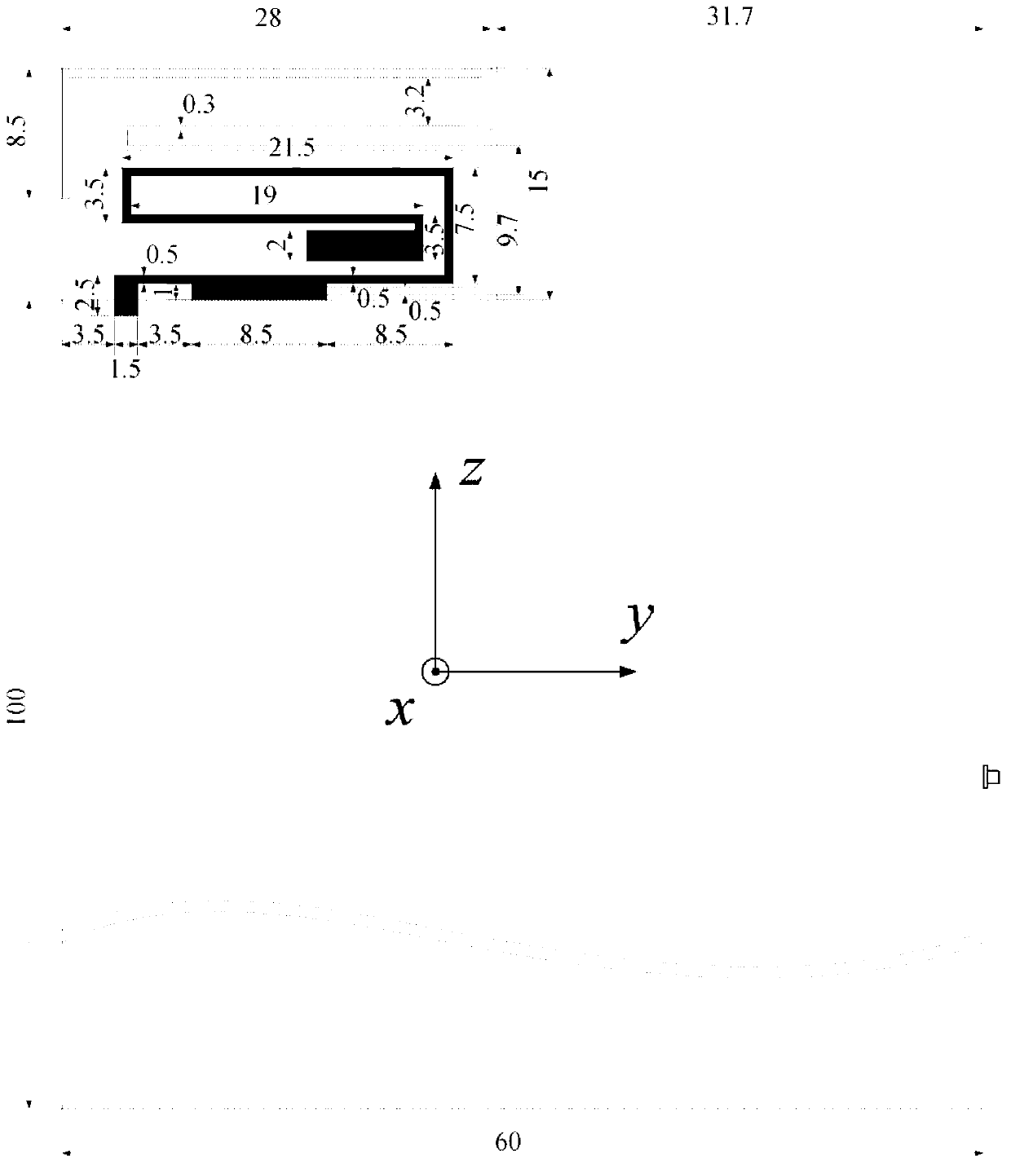

[0031] The present invention provides a multi-frequency planar printed antenna with a protruding floor applied to a mobile terminal. The specific implementation scheme is as follows:

[0032] The structure of each part of the planar printed antenna is printed on a dielectric board 0 using a double-layer printed circuit board process. The main floor 1 printed on the lower back of the dielectric board 0 is used to simulate the circuit part of the circuit board. Printed on the back of the media board 0, located on the upper right of the main floor 1 and connected to the protruding floor 2 of the main floor 1, for electronic equipment that may be needed, such as digital cameras, speakers, data ports, power supply and headphone jacks, etc. Space for placement. The main part of the antenna consists of the excitation branch 3 printed on the front of the dielectric board 0 and the parasitic ground branch 4 printed on the back of the dielectric board 0. The antenna's low frequency band ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com