Method for photoelectrically detecting nitrogen dioxide with trace amount

A nitrogen dioxide, photoelectric detection technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of low detection limit and high working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Fabrication of resistive sensors:

[0024] Fix the electrode 2 on the ceramic substrate 1, connect the electrode 2 through the sensitive material titanium dioxide / graphene 3, connect the electrode 2 to the signal processor 5, and fix the heater and thermocouple 4 on the bottom of the ceramic substrate 1 to form a resistive sensor;

[0025] Photoelectric detection NO 2 Methods:

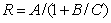

[0026] Add a light-emitting diode (LED) light source 6 with a wavelength of 367 nm directly above the resistive sensor, such as figure 1 As shown, the sensor is placed in the presence of a known concentration of NO 2 In atmosphere, at a temperature of 220°C and a light source of 6 9 W / m 2 Under the condition of light intensity, irradiate the sensitive material titanium dioxide / graphene composite material 3, and use the resistance change of titanium dioxide / graphene composite material 3 as a signal to calibrate the sensor;

[0027] The sensor was then exposed to an unknown concentration of NO...

Embodiment 2

[0029] The making of resistive sensor is carried out according to embodiment 1;

[0030] Photoelectric detection NO 2 Methods:

[0031] Add Xe light source 6 obliquely above the resistive sensor, use gratings, filters, lenses and mirrors to process the light into monochromatic light, so that the light with a wavelength of 200 nm is irradiated on the sensitive material titanium dioxide / graphene composite material 3; The absorption of different wavelengths of light by titanium dioxide / graphene composite material 3 is as follows: figure 2 As shown, the sensor is placed in the presence of a known concentration of NO 2 In atmosphere, at room temperature and light source 6: 0.001 W / m 2 Under the condition of light intensity, the sensor is calibrated by using the resistance change of the sensitive material titanium dioxide / graphene composite material 3 as a signal;

[0032] The sensor was then exposed to an unknown concentration of NO 2 In an atmosphere of 0.001 W / m at room tem...

Embodiment 3

[0034] Fabrication of resistive sensors:

[0035] Fix the electrode 2 on the ceramic substrate 1, connect the electrode 2 through the sensitive material nickel oxide 3, connect the electrode 2 to the signal processor 5, and fix the heater and the thermocouple 4 on the bottom of the ceramic substrate 1 to form a resistive sensor;

[0036] Photoelectric detection NO 2 Methods:

[0037] Add Xe light source 6 directly above the resistive sensor, such as figure 1 As shown, the sensor is placed in the presence of a known concentration of NO 2 In the atmosphere, the resistance change of the sensitive material nickel oxide material 3 is used as a signal, and the temperature is 100°C and the light source 6 is 0.001 W / m 2 Under the condition of light intensity, calibrate the sensor;

[0038] The sensor was then exposed to an unknown concentration of NO 2 In an atmosphere of 0.001 W / m at a temperature of 100°C and a light source 6 2 Under the condition of light intensity, for trace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com