Sterilizable assembly bracket for sterile operation experiment

一种无菌操作、组装支架的技术,应用在灭菌的方法、试管支架/夹、组织细胞/病毒的培养装置等方向,能够解决影响试验结果准确等问题,达到提高准确度及效率、角度可调、结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

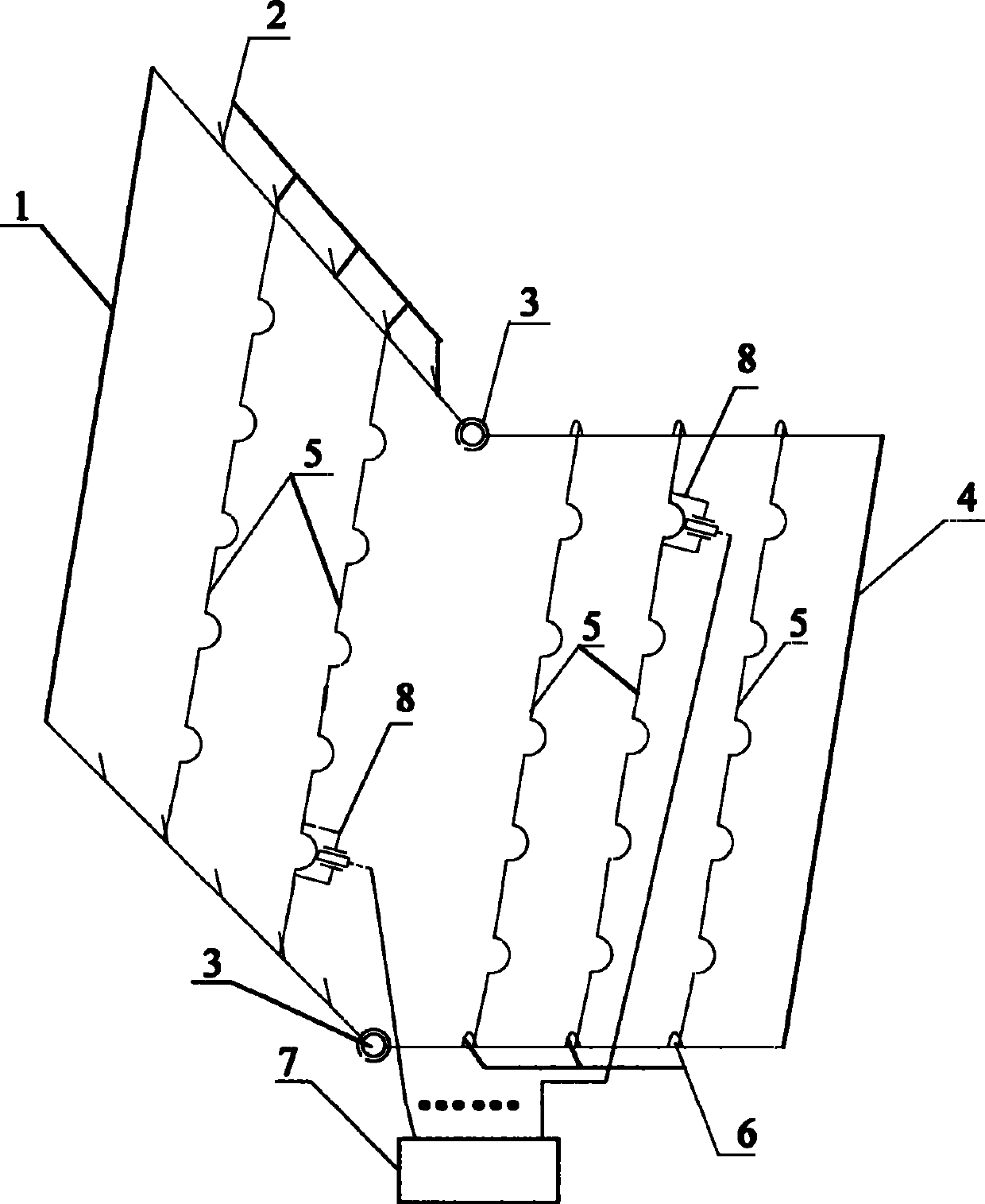

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the sterilizable assembly bracket for the aseptic operation experiment described in this embodiment, which includes a frame 1, a retaining wire 2, a connector 3, a bottom frame 4, and a heat-resistant rod with a plurality of semicircular positioning rings 5. Connecting ring 6, temperature display control unit 7 and N temperature sensors 8, N is an integer greater than or equal to 1, frame 1 and bottom frame 4 are U-shaped frames with the same size, and frame 1 and bottom frame 4 pass through connectors 3 connections, frame 1 U-shaped arms are symmetrically provided with multiple retaining wires 2, heat-resistant rods 5 are placed horizontally on the retaining wires 2, bottom frame 4 U-shaped arms are symmetrically provided with multiple connecting rings 6, and heat-resistant rods 5 are fixed on The connection ring 6 is parallel to the heat-resistant rod 5 on the frame 1, and N temperature senso...

specific Embodiment approach 2

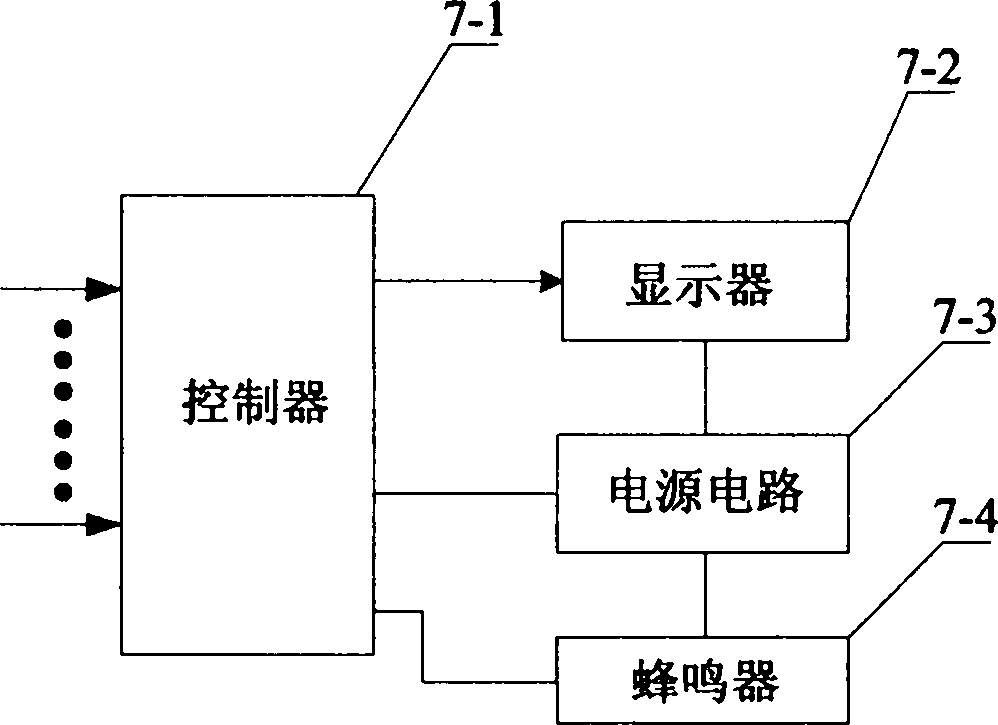

[0009] Specific implementation mode two: combination figure 2 Describe this embodiment. This embodiment is a further limitation of the aseptic operation experiment sterilizable assembly bracket described in Embodiment 1. The temperature display control unit 7 includes a controller 7-1, a display 7-2, and a power circuit 7- 3 and buzzer 7-4, the power output end of power supply circuit 7-3 corresponds to the power input end of controller 7-1, the power input end of display 7-2 and the power input end of buzzer 7-4 respectively Connected, the input ends of the N temperature sensing signals of the controller 7-1 are correspondingly connected with the output ends of the sensing signals of the N temperature sensors 8, and the output ends of the display signals of the controller 7-1 are connected with the output ends of the display 7-2. The input end of the display signal is connected, and the output end of the buzzer start control signal of the controller 7-1 is connected with the...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 This embodiment is described. This embodiment is a further limitation of the aseptic operation experiment sterilizable assembly bracket described in Embodiment 2, and the controller 7-1 adopts a single-chip microcomputer.

[0011] Specific implementation mode four: combination figure 1 This embodiment is described. This embodiment is a further limitation of the aseptic operation experiment sterilizable assembly bracket described in Embodiment 1. The positioning rings on the heat-resistant rod 5 are evenly distributed.

[0012] Specific implementation mode five: combination figure 1 This embodiment is described. This embodiment is a further limitation of the aseptic operation experiment sterilizable assembly bracket described in Embodiment 1. Both the frame 1 and the bottom frame 4 are heat-resistant frames.

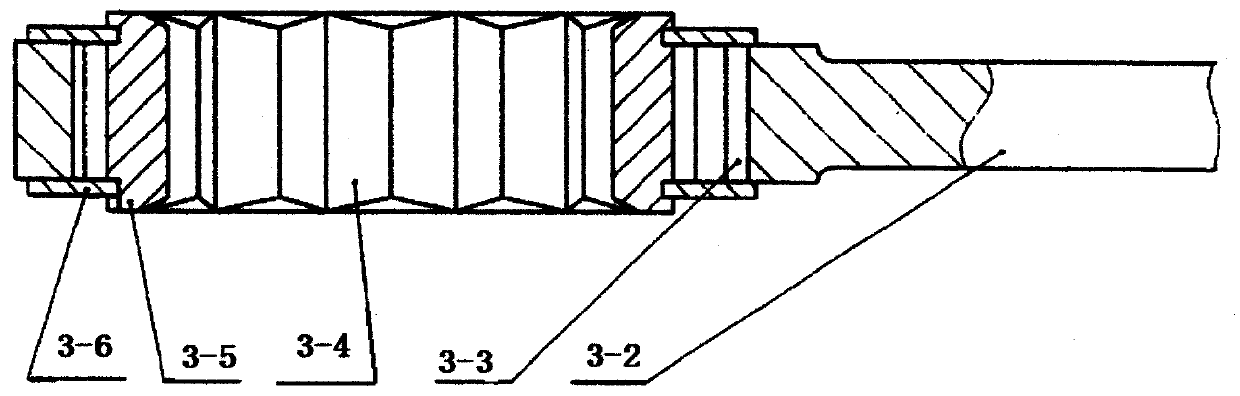

[0013] Specific implementation mode six: combination image 3 , Figure 4 This embodiment is describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com