A kind of multifunctional scrubbing oxygen particle and preparation method thereof

A multi-functional, granule technology, applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of poor washing effect, human hazards, etc., achieve short washing time, high granulation rate, no The effect of return material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

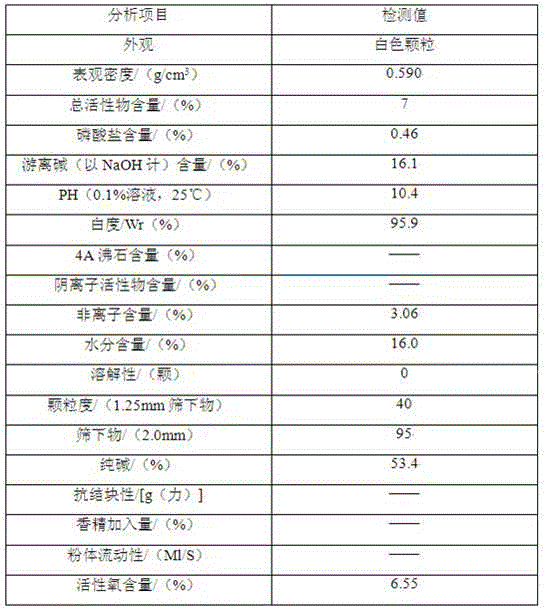

Image

Examples

Embodiment 1

[0032] The present invention is mainly applied to the washing of clothes, towels, quilt covers and other items composed of various materials such as cotton, hemp, silk, and wool synthetic fibers, and can also be applied to the washing of household and kitchen tableware. Stain-removing, germ-killing, bleaching and deodorizing capabilities. Specifically, the oxygen granules in the present invention are formulated from raw materials with the following mass ratios:

[0033] Sulfonic acid: 5% to 10%;

[0034] Sodium carbonate: 25% to 35%;

[0035] Sodium sulfate: 10% to 25%;

[0036] Sodium percarbonate: 25% to 59%;

[0037] Sodium carboxymethyl cellulose: 1% to 5%.

[0038] Using the above-mentioned raw materials, this embodiment prepares raw materials according to a certain mass ratio, and prepares washing oxygen particles through a preparation process. The preparation process includes the following steps:

[0039] (1) Preparation of raw materials: sulfonic acid, sodium carb...

Embodiment 2

[0052]The difference with Example 1 is that in the present example, the mass ratios of the sulfonic acid, sodium carbonate, sodium sulfate, sodium percarbonate and sodium carboxymethylcellulose are respectively: sulfonic acid 7.5%, sodium carbonate 30% %, sodium sulfate 17.5%, sodium percarbonate 42%, sodium carboxymethylcellulose 3%. The preparation process of this embodiment is the same as that of Example 1. Under this proportioning ratio, since the sodium percarbonate composition is slightly less than that of Example 1, its performance is moderate, and it is more suitable for washing clothes, and is usually used in frequent washing environments such as laundry rooms, hospitals, and hotels.

Embodiment 3

[0054] The difference with Example 1 is that in the present example, the mass ratios of the sulfonic acid, sodium carbonate, sodium sulfate, sodium percarbonate and sodium carboxymethylcellulose are respectively: sulfonic acid 10%, sodium carbonate 35% %, sodium sulfate 25%, sodium percarbonate 25%, sodium carboxymethylcellulose 5%. The preparation process of this embodiment is the same as that of Example 1. Under this ratio, sodium percarbonate has the least ingredients, so its washing effect is relatively poor, but its deodorizing and bleaching effects are very prominent, and it is more suitable for items that are not easy to get dirty, such as dining tables, furniture, etc. that do not require high decontamination. items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com