Crosslinked vinyl acetate-acrylic emulsion for digital color inkjet ink-absorbing coating and preparation method thereof

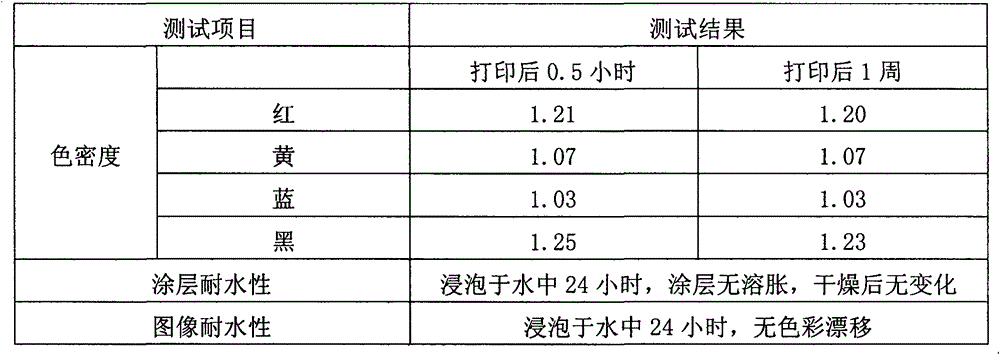

A technology of ink-absorbing coating and vinegar-acrylic emulsion, applied in the direction of coating, etc., can solve the problems of emulsion stability decline, difficult control of viscosity, cost increase, etc., and achieve printing with bright colors, excellent water resistance and strong impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

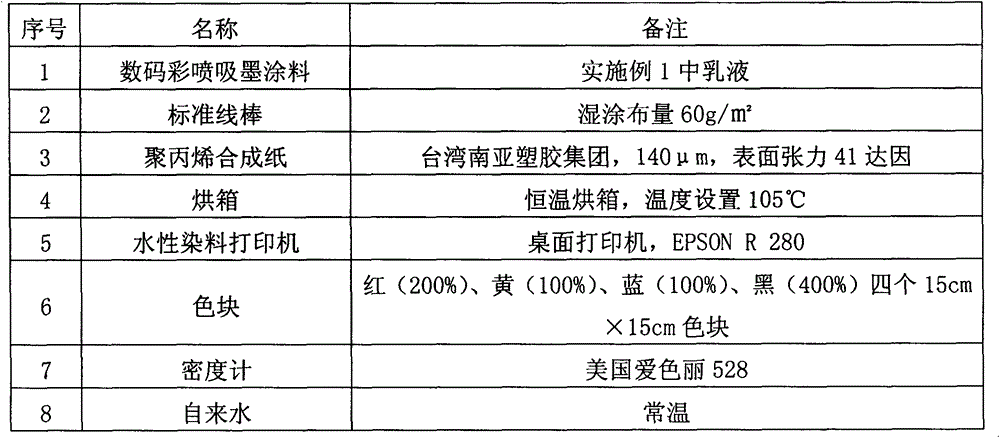

Examples

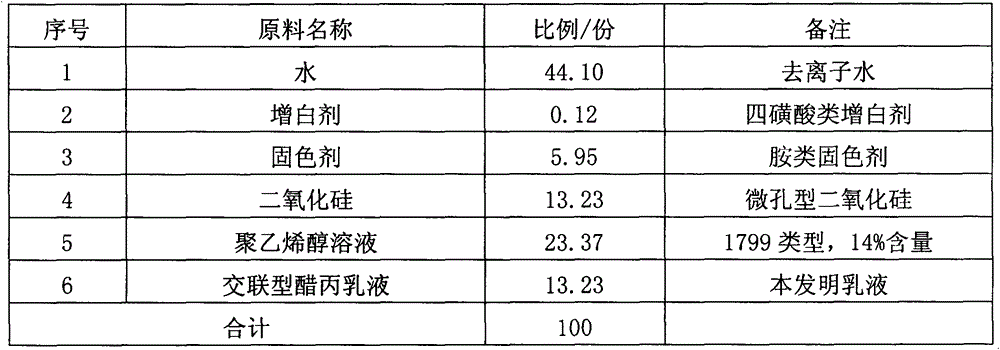

Embodiment 1

[0027] A kind of cross-linked vinegar-acrylic emulsion for digital color-jet ink-absorbing coating, which is composed of the following components by weight in the total amount of the emulsion: 15 parts of vinyl acetate; 3.1 parts of acrylic acid; 0.9 parts of methacrylic acid; N - 0.03 parts of methylol acrylamide, 0.3 parts of a mixture of sodium lauryl sulfate and OP-10; 17881.5 parts of polyvinyl alcohol; 0.03 parts of ammonium persulfate; 0.03 parts of disodium hydrogen phosphate, and 79.11 parts of water.

[0028] The preparation method of the cross-linked vinegar-acrylic emulsion for the above-mentioned digital color-jet ink-absorbing coating comprises the following steps:

[0029] 1) Preparation of monomer mixture: mix vinyl acetate, acrylic acid, methacrylic acid, and N-methylol acrylamide with 80% water according to the above ratio to obtain a monomer mixture, which is set aside;

[0030] 2) Preparation of the pre-emulsion: get 10% of the weight of the monomer mixture...

Embodiment 2

[0037] A kind of cross-linked vinegar-acrylic emulsion for digital color-jet ink-absorbing coating, which is composed of the following components by weight in the total amount of the emulsion: 28 parts of vinyl acetate, 12.4 parts of methyl acrylate, methyl methacrylate 9.3 parts, 1.5 parts of N-isopropoxymethacrylamide, 1.5 parts of a mixture of sodium dodecylsulfonate and NP-10, 3 parts of hydroxyethyl cellulose, 0.3 parts of potassium persulfate, 0.3 parts of disodium hydrogen phosphate , add 43.7 parts of water.

[0038] The preparation method of the cross-linked vinegar-acrylic emulsion for the above-mentioned digital color-jet ink-absorbing coating comprises the following steps:

[0039] 1) Preparation of the monomer mixture: mix vinyl acetate, methyl acrylate, methyl methacrylate, and N-isopropoxymethacrylamide with 80% by weight of water in proportion to obtain the monomer mixture, spare;

[0040] 2) Preparation of the pre-emulsion: take 50% of the weight of the mono...

Embodiment 3

[0047] A cross-linked vinegar-acrylic emulsion for digital color-jet ink-absorbing coating, which is composed of the following components by weight in the total amount of the emulsion: 20 parts of vinyl acetate, 10 parts of ethyl acrylate, 10 parts of ethyl methacrylate 5 parts, 1 part of N-isopropoxymethacrylamide, 1 part of sodium dodecylbenzenesulfonate and OP-20 mixture, 17992 parts of polyvinyl alcohol, 0.1 part of ammonium persulfate, 0.1 part of sodium bicarbonate, plus moisture.

[0048] A kind of preparation method of above-mentioned digital color-jet ink-absorbing coating cross-linked type vinegar acrylic emulsion, comprises the steps:

[0049] 1) Preparation of the monomer mixture: mix vinyl acetate, ethyl acrylate, ethyl methacrylate, and N-isopropoxymethacrylamide with 80% by weight of water in proportion to obtain the monomer mixture, spare;

[0050] 2) Preparation of pre-emulsion: get step 1) 30% of the weight of the monomer mixed solution obtained in the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com