Masonry plastering anticracking agent

An anti-cracking agent and masonry technology, which is applied in the field of mortar admixture, can solve problems such as frequent engineering quality problems, research and development lag, and failure, so as to improve the quality of construction projects, solve matching problems, and simplify the mortar ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, a kind of masonry plastering anti-cracking agent, it is made up of the composition of following weight content:

[0031] Active silica 2.5%, redispersible latex powder (Vac / E) 5%, inorganic gel 7.5%, sodium bentonite 20%, UF type urea-formaldehyde resin 5%, sodium dodecylbenzenesulfonate 2.5%, 17.5% naphthalene superplasticizer, 2.5% sodium lauryl sulfate, 15% methyl cellulose, 2% anhydrous sodium pyrophosphate, 20% silica fume (5000 mesh fineness), 5-6mm long poly Acrylic fiber 0.5%.

[0032] Put various raw materials into a coulter-type gravity-free mixer, stir and mix evenly until there is no agglomeration or agglomeration, and then the masonry plastering anti-cracking agent is obtained.

Embodiment 2

[0033] Embodiment 2, a kind of masonry plaster anti-cracking agent, it is made up of the composition of following weight content:

[0034] Active silica 2.2%, redispersible latex powder (Vac / E) 5.5%, inorganic gel 7%, sodium bentonite 21%, UF type urea-formaldehyde resin 4.5%, sodium dodecylbenzene sulfonate 2.8%, 18% naphthalene superplasticizer, 2.8% sodium lauryl sulfate, 14.5% methyl cellulose, 1.7% anhydrous sodium pyrophosphate, 19.4% silica fume (5000 mesh fineness), 5-6mm long poly Acrylic fiber 0.6%.

[0035] The preparation method is identical to Example 1.

Embodiment 3

[0036] Embodiment 3, a kind of masonry plaster anti-cracking agent, it is made up of the composition of following weight content:

[0037] Active silica 2.8%, redispersible latex powder (Vac / E) 4.5%, inorganic gel 7.9%, sodium bentonite 19%, UF type urea-formaldehyde resin 5.5%, sodium dodecylbenzenesulfonate 2.2%, Naphthalene superplasticizer 17%, sodium lauryl sulfate 2.2%, methyl cellulose 15.4%, anhydrous sodium pyrophosphate 2.3%, silica fume (5000 mesh fineness) 20.8%, length 5-6mm Acrylic fiber 0.4%.

[0038] The preparation method is identical to Example 1.

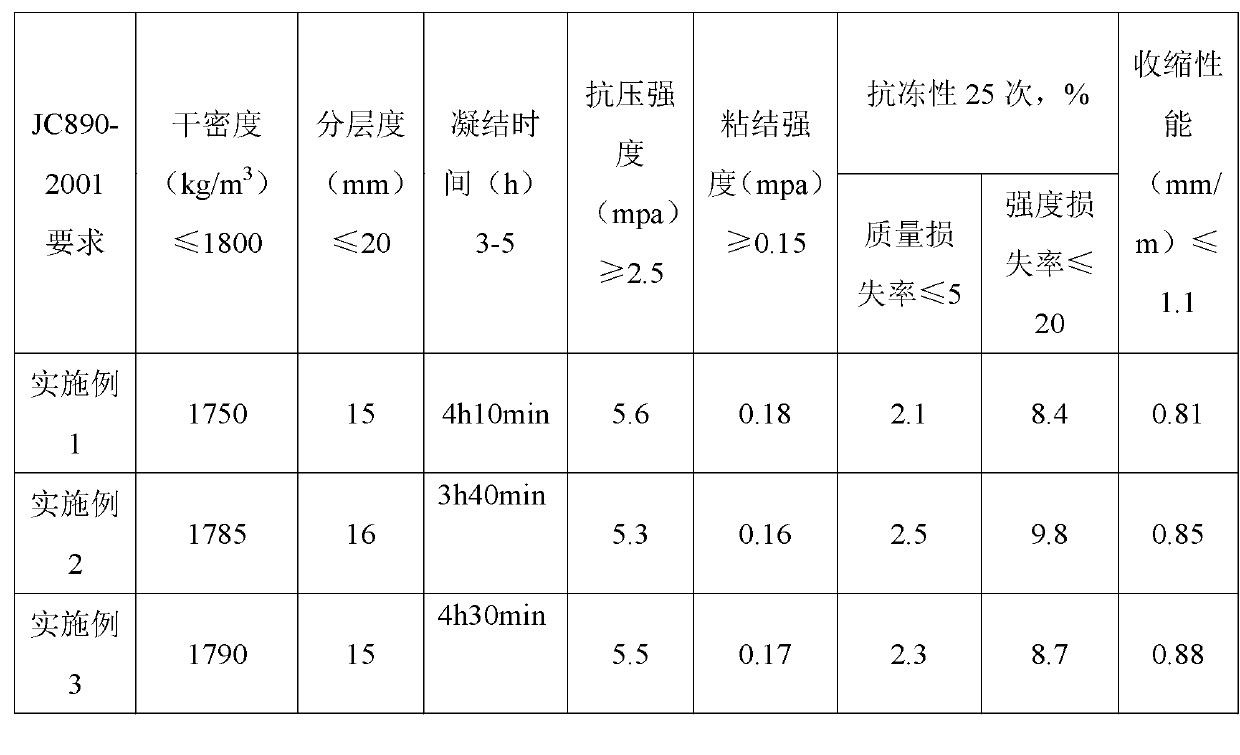

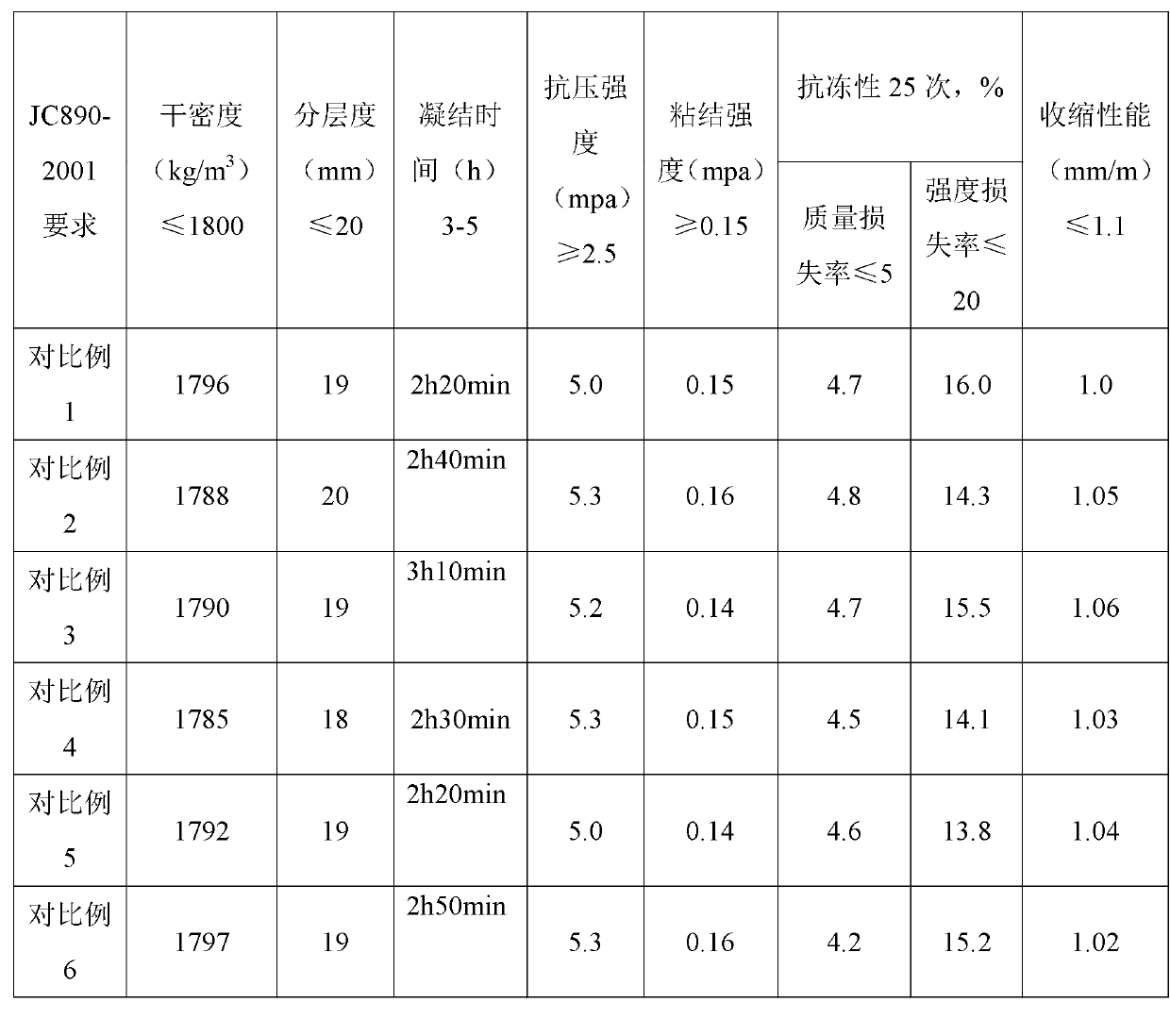

[0039] In order to verify the performance of the anti-cracking agent for masonry plastering of the present invention, the inventor has done an applicability test on the anti-cracking agent for masonry plastering (taking the proportion of M5.0 cement-based plastering mortar as an example), the results are as follows:

[0040] 1. Raw materials and admixtures for testing

[0041] 1. Cement: Nanfang brand 32.5 ordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com